Patents

Literature

36results about How to "Easy to quench" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

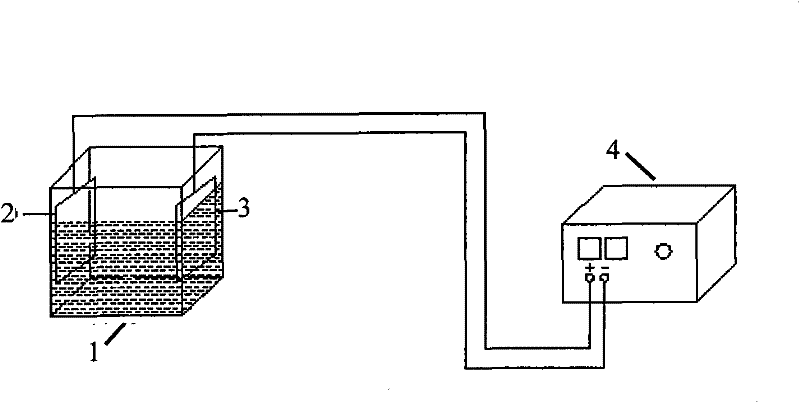

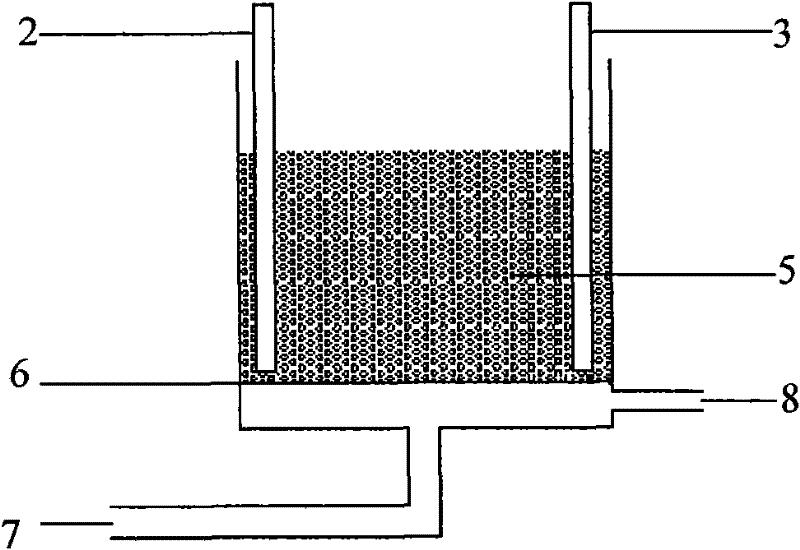

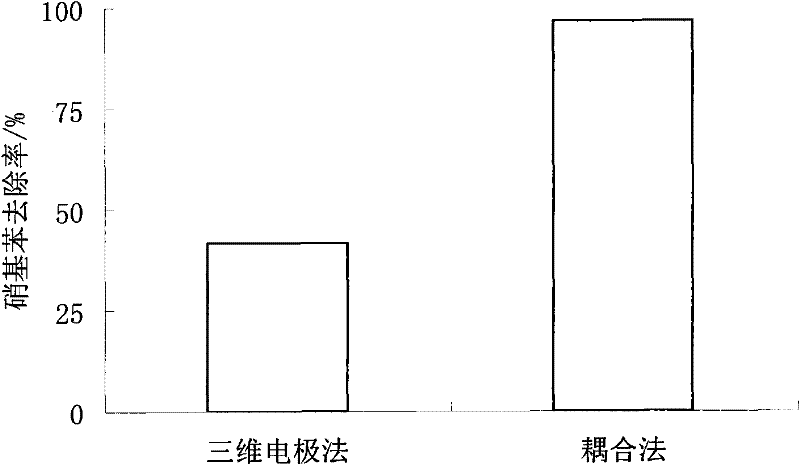

Method for degrading nitrobenzene waste water by polyphase electrocatalytic oxidation-Fenton coupling process and reactor thereof

ActiveCN101838074AGuaranteed emission standardsPromote generationMultistage water/sewage treatmentWater/sewage treatment by oxidationCarbon dioxideHigh concentration

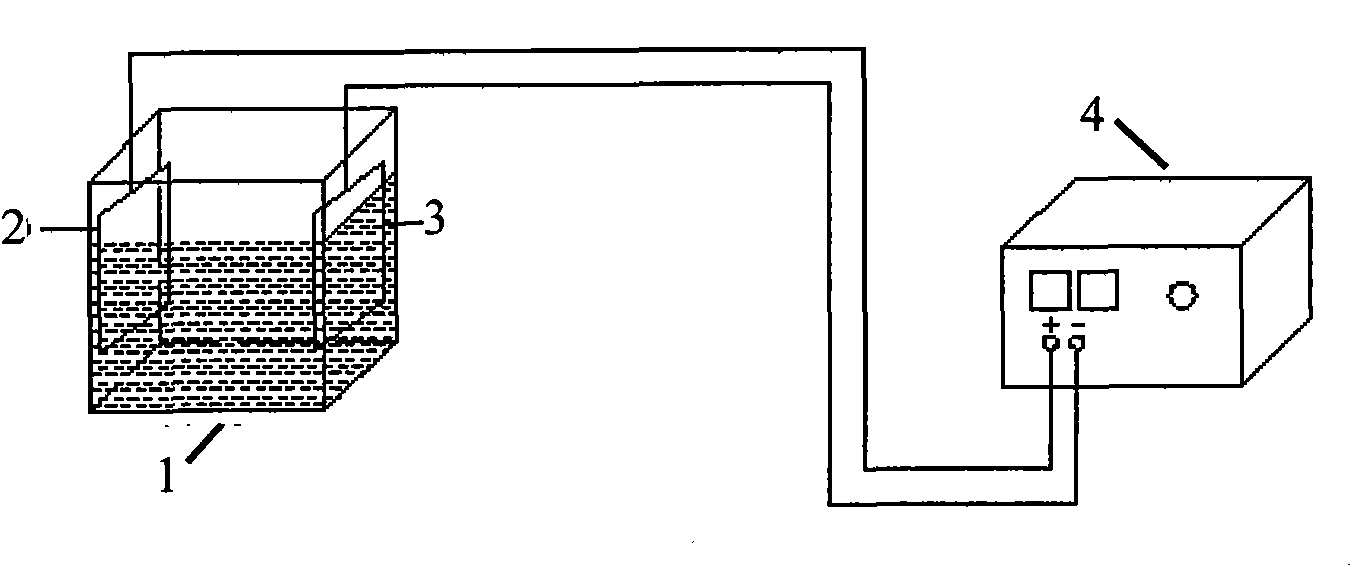

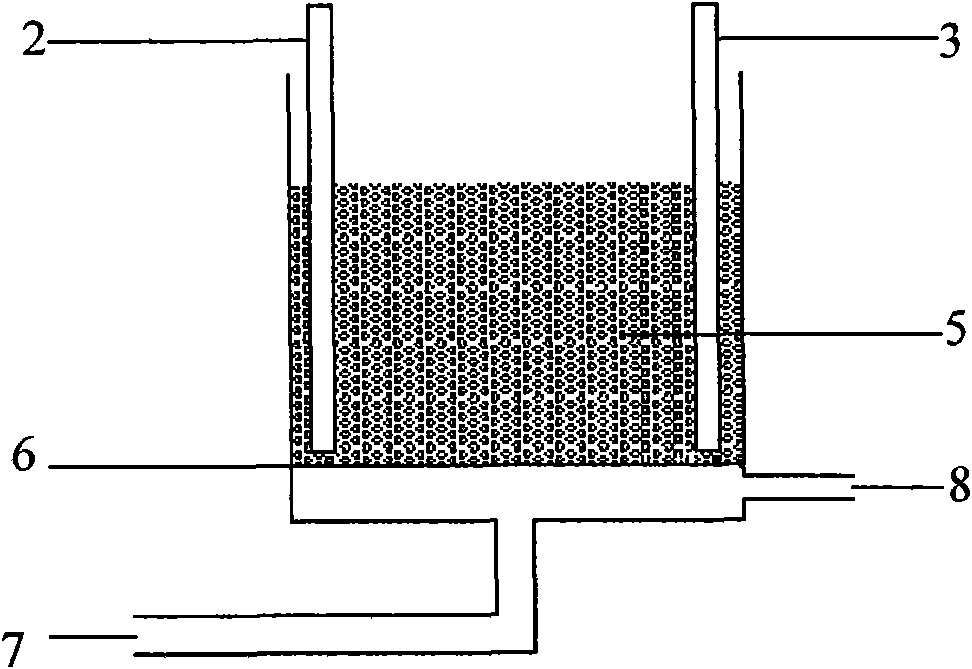

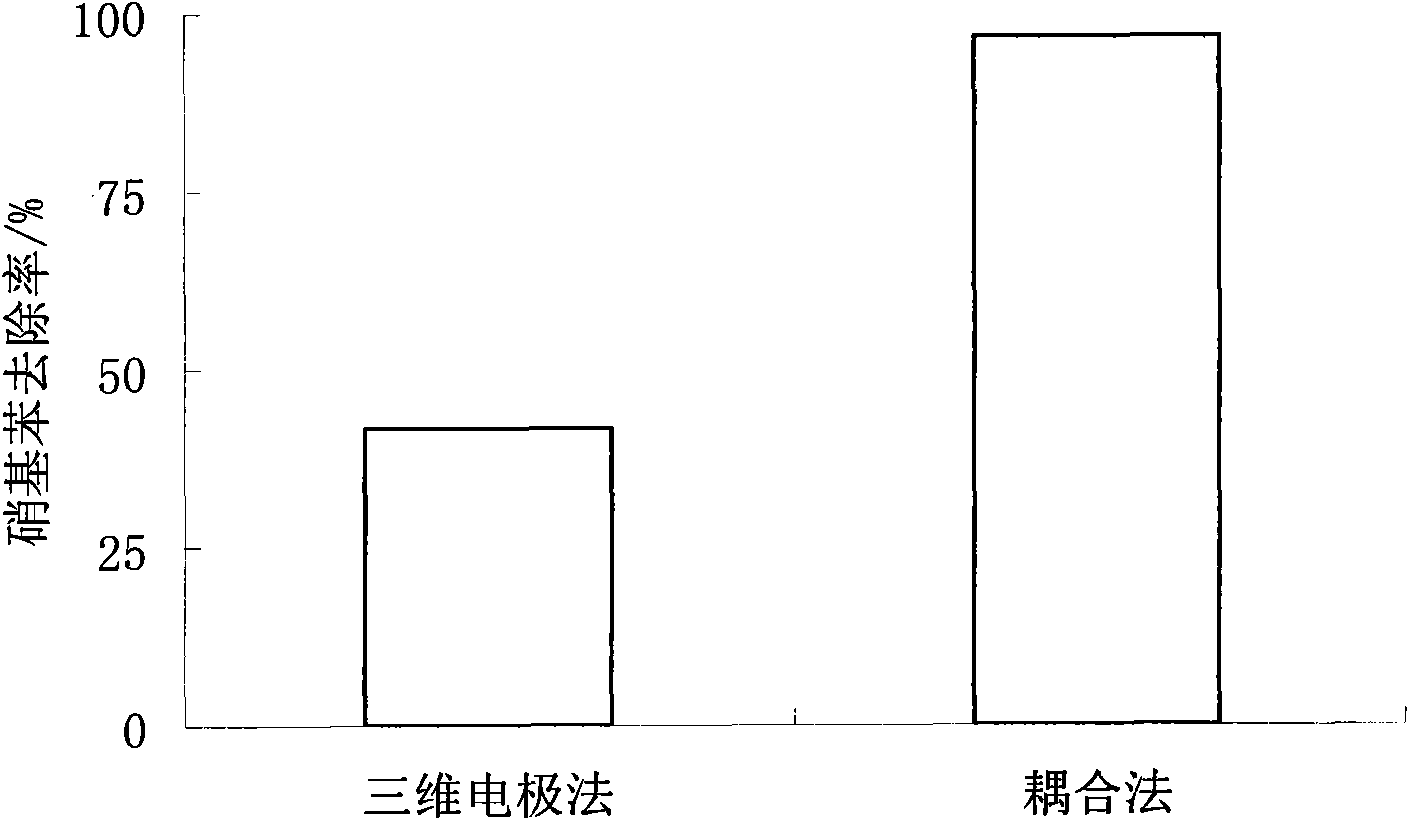

The invention belongs to the technical field of treatment of high concentration organic waste water, and particularly relates to a method for degrading nitrobenzene waste water by a polyphase electrocatalytic oxidation process. The invention solves the problems of high cost and long time consumption in the traditional nitrobenzene waste water methods, low efficiency and high energy consumption in the electrolytic process, high oxidant consumption, high cost and the like in the Fenton process in the prior art for treating high concentration nitrobenzene water waste. The invention mainly adopts the catalytic oxidation action of transition metal catalysts in the electric field, and combines the Fenton process, thereby effectively degrading the high concentration nitrobenzene waste water. The method comprises the following steps that: (1) heterocatalytic reagents (solid catalysts) and particle electrodes, mainly including active carbon, and transition metal oxides and salts, are used for avoiding economic loss and secondary pollution to the environment, which are caused by catalyst loss in heterocatalytic oxidation; (2) under the condition of low pH value of the waste water in cooperation with Fe2+ with strong reducibility, a coupling reactor composed of an electrolysis field and oxidation reaction is used for generating chain reaction for generating an OH hydroxyl free radical, and the OH hydroxyl free radical can carrying out nonselective oxidization on organic substances, thereby finally oxidizing organic pollutants into carbon dioxide and water; (3) by using electric energy as an excitation energy and using cheap air as raw material, nitrobenzene substances in waste water are efficiently degraded under the coupling action of the polyphase electrocatalytic oxidation process and the Fenton process; (4) and the reactor is composed of a direct current regulated power supply, a feed electrode and an electrolytic bath.

Owner:广东华凯明信科技有限公司

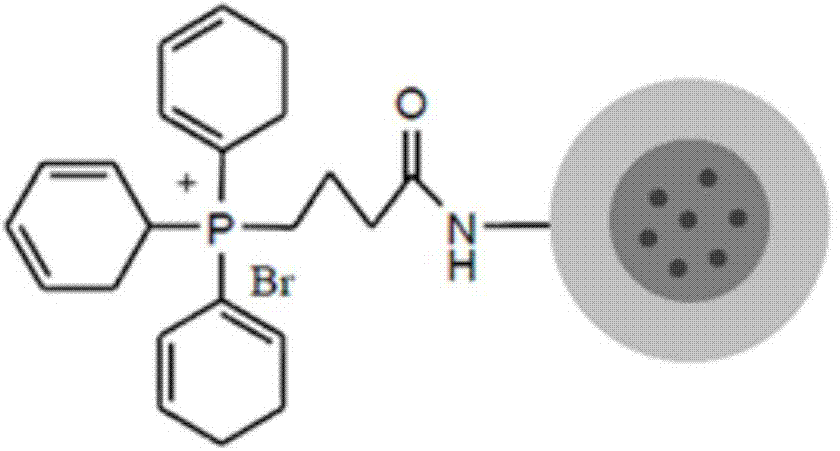

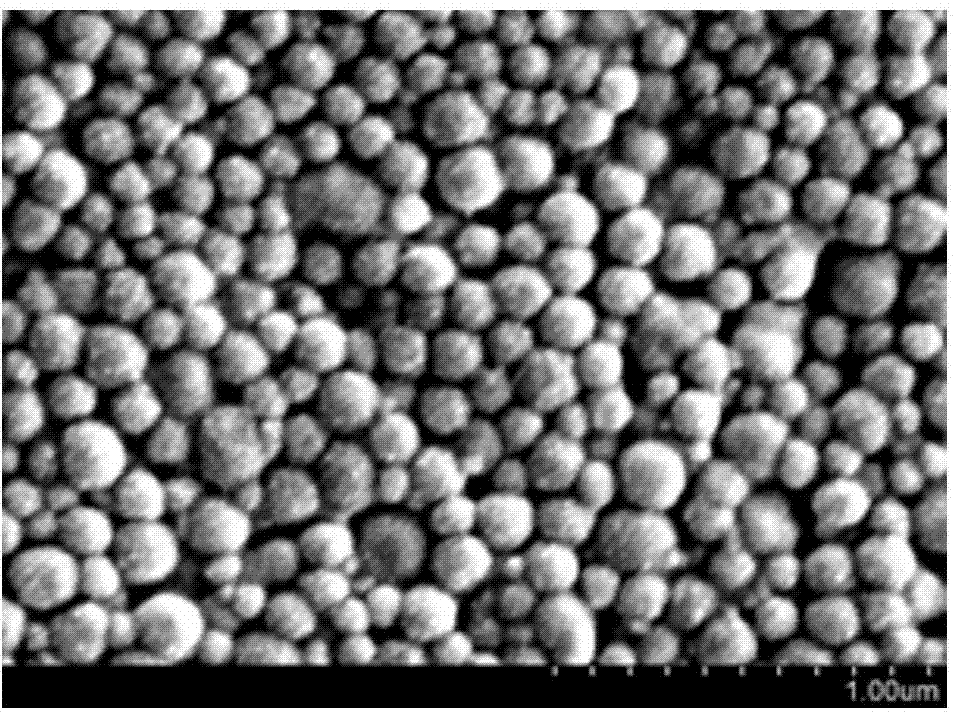

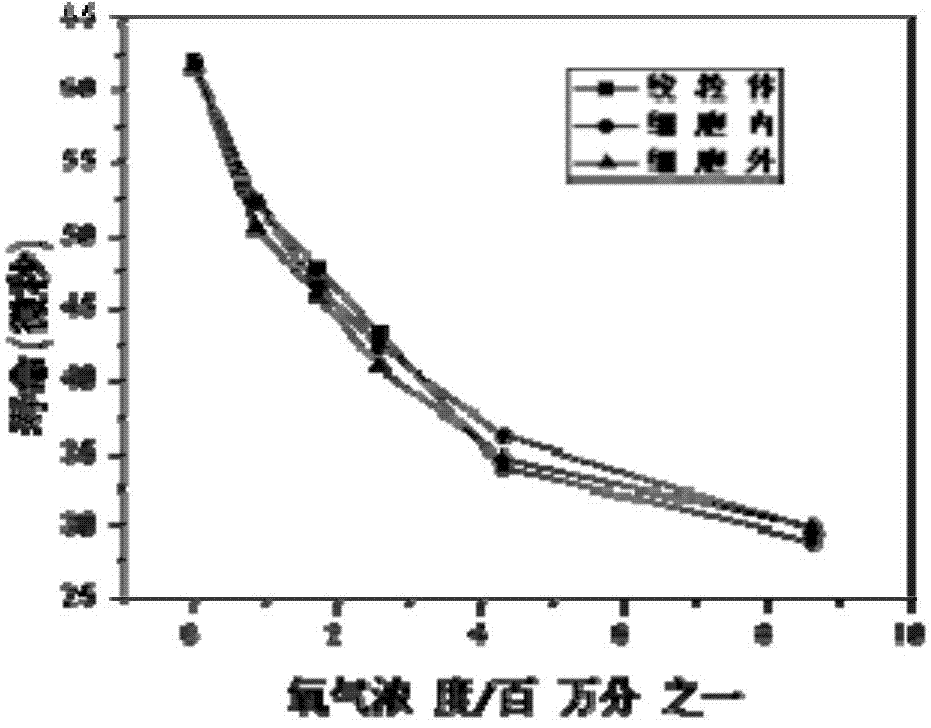

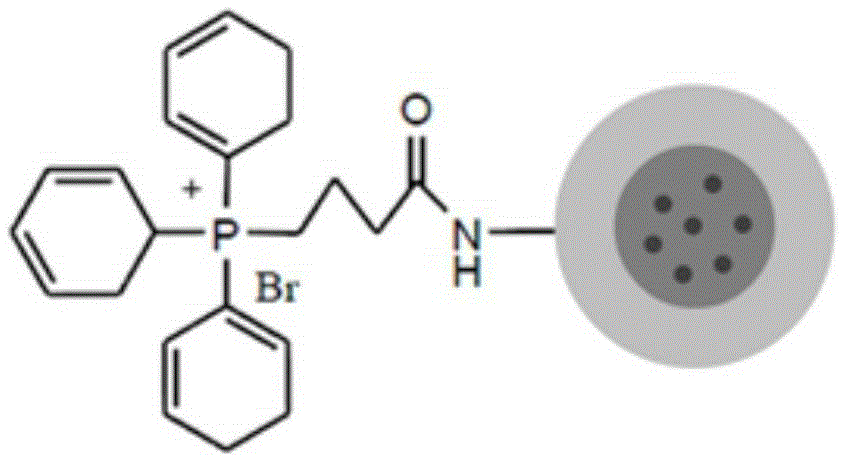

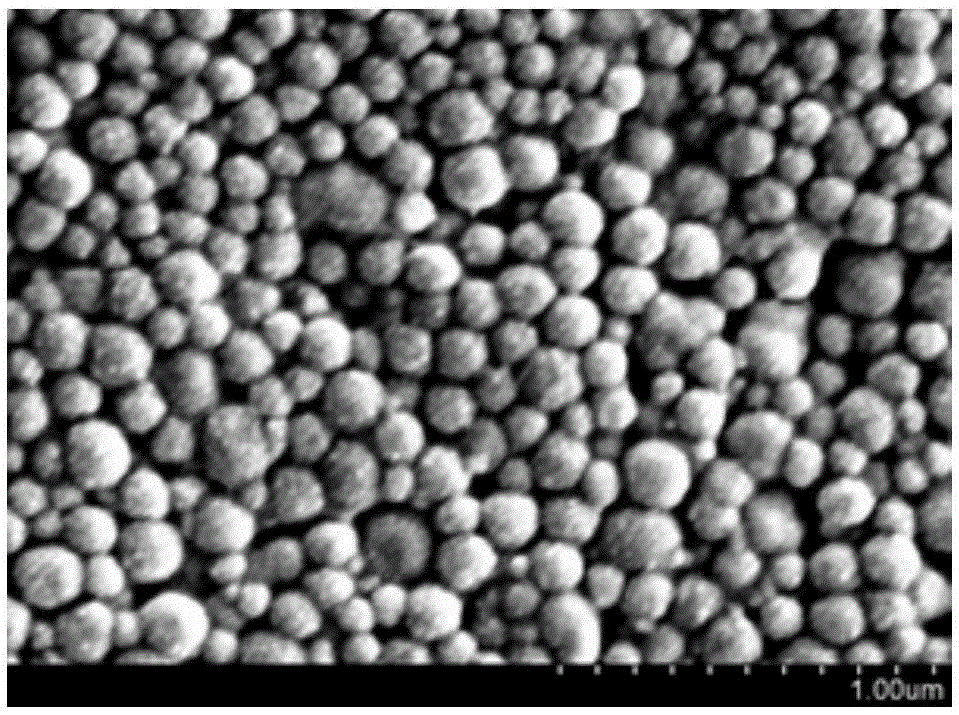

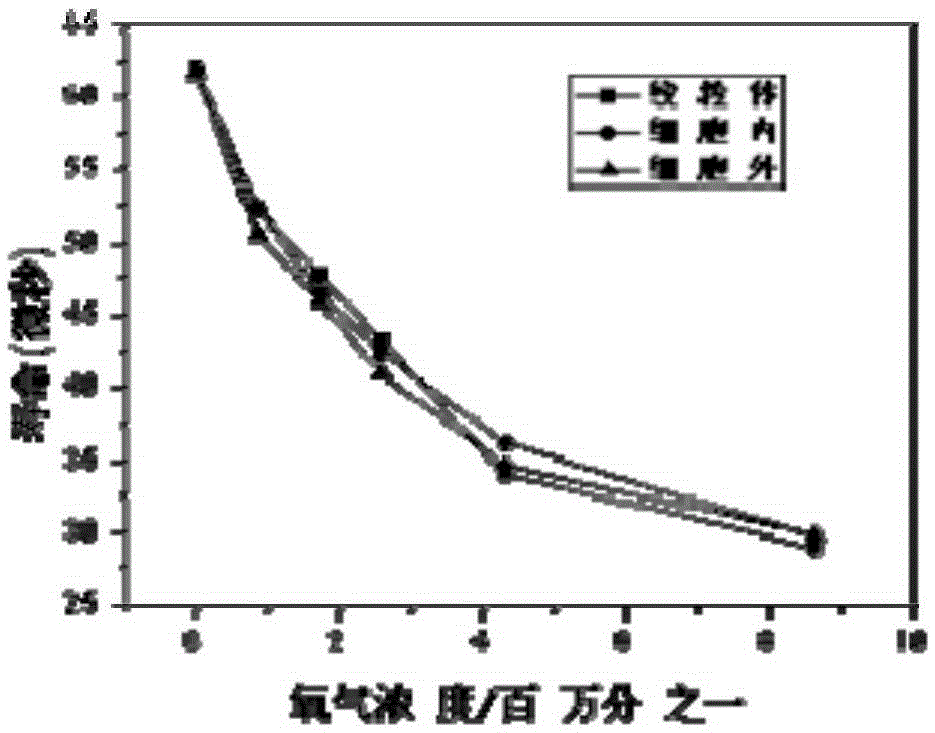

Fluorescent oxygen nano sensor with cellular mitochondrion targeting, and preparation method of nano sensor

InactiveCN103575717AStrong targetingGood biocompatibilityNanostructure manufactureFluorescence/phosphorescenceBiological bodyInterference resistance

The invention discloses a fluorescent oxygen nano sensor with cellular mitochondrion targeting. The nano sensor has the fluorescent service life sensitive to dissolved oxygen quantity, and can specifically target a mitochondrion in a cell. After the cell phagocytizes the oxygen nano sensor, variations of the dissolved oxygen quantity in a cytoplasm and the mitochondrion can be detected by a variation of the fluorescent service life of the nano sensor. The fluorescent oxygen nano sensor with the cellular mitochondrion targeting has the following characteristics that (1) a PLL (Phase Locked Loop) housing layer allows the sensor to have good organism compatibility; encapsulation allows a probe to have external interference resistance; (2) the mitochondrion targeting is good; (3) the oxygen sensitivity of the fluorescent service life is high; (4) the dissolved oxygen quantity in different positions in the cell can be detected.

Owner:BEIJING JIAOTONG UNIV

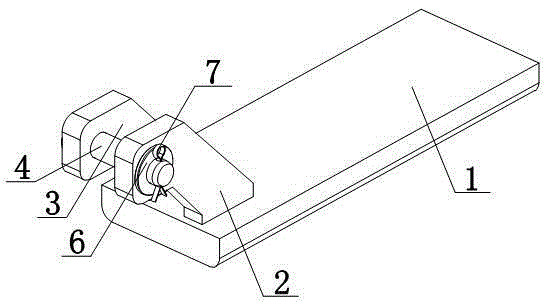

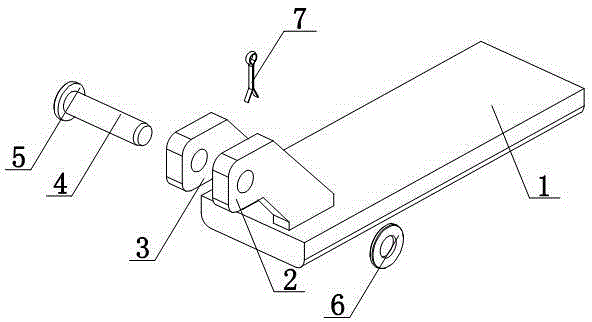

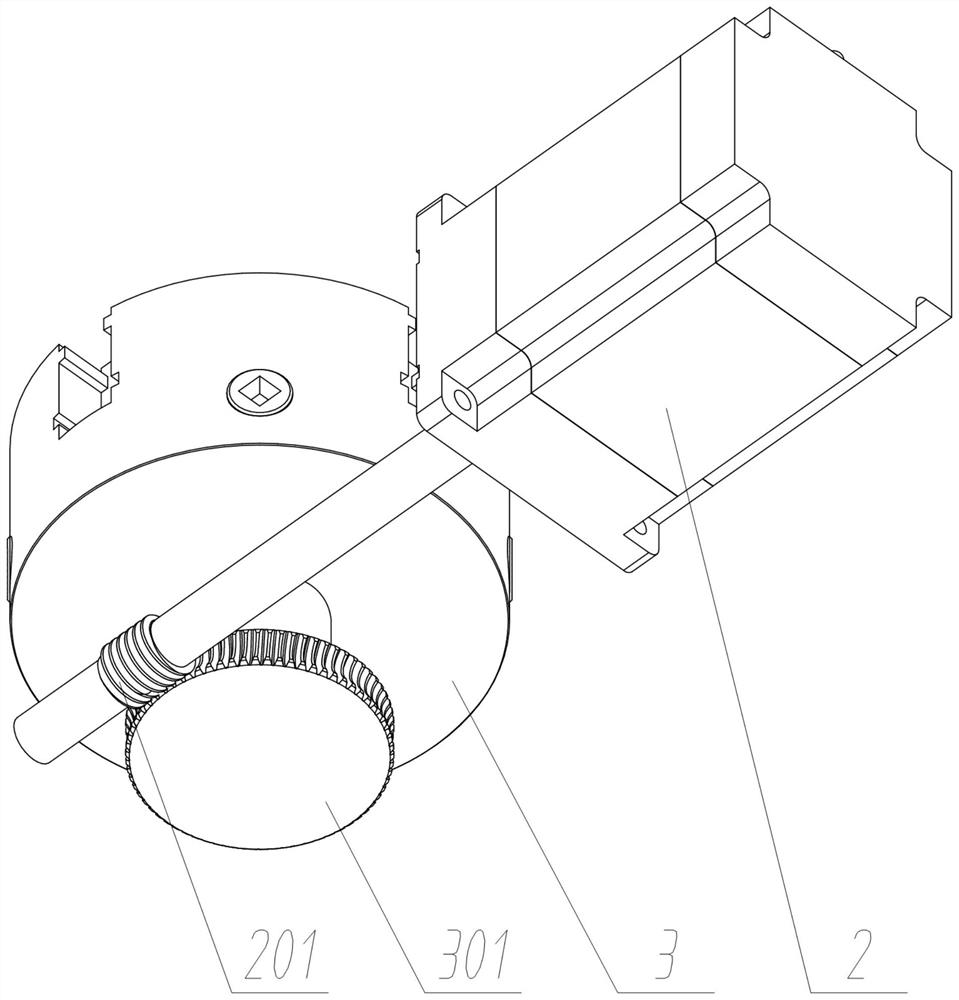

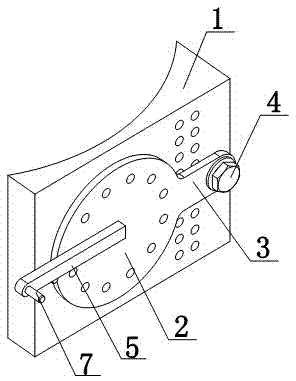

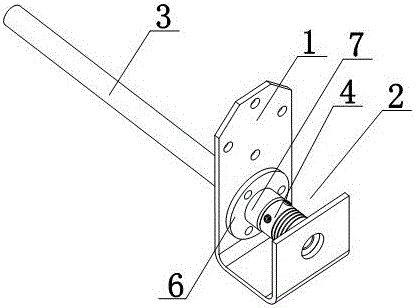

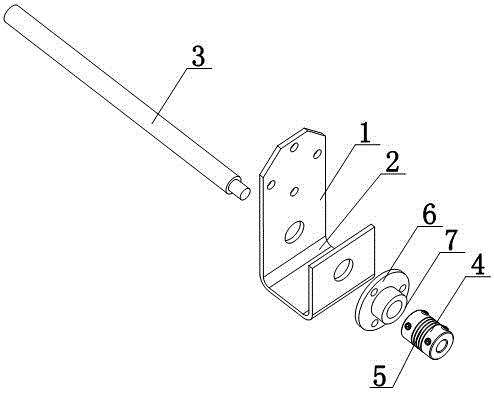

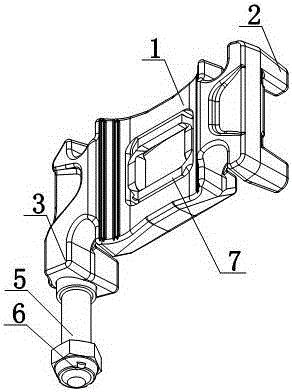

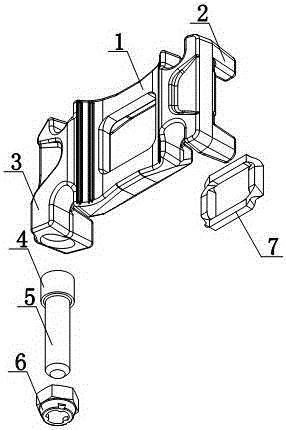

Gear surface hardening adjusting bracket

The invention discloses a gear surface hardening adjusting bracket which comprises a fixed plate. A mounting rack is arranged on the fixed plate; a mounting groove is formed in the mounting rack; an inserted rod is connected with the mounting rack in an inserting manner; a retaining ring is arranged at one end of the inserted rod and is buckled on one side of the mounting rack; a locking ring is arranged at the other end of the inserted rod and is buckled on the other side of the mounting rack. According to the invention, a to-be-treated gear can be mounted in the mounting groove and is mounted on the outer surface of the inserted rod in a sleeving manner, and then the adjusting bracket is moved to hardening equipment, so that the hardening treatment performed on the gear is facilitated.

Owner:岳文智

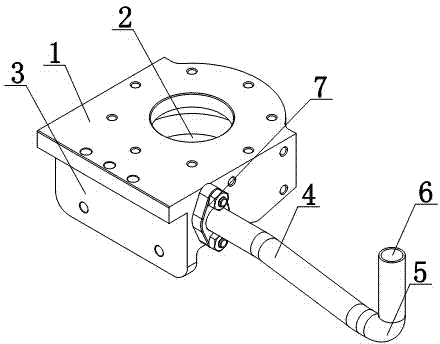

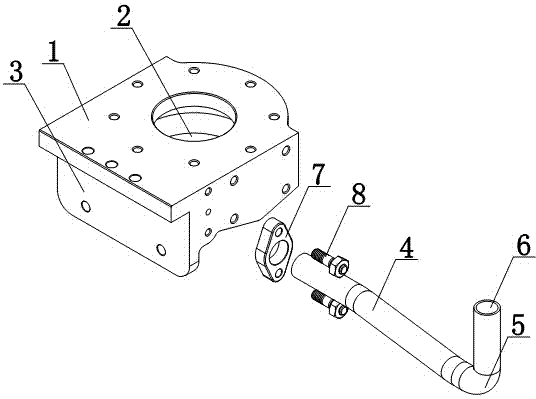

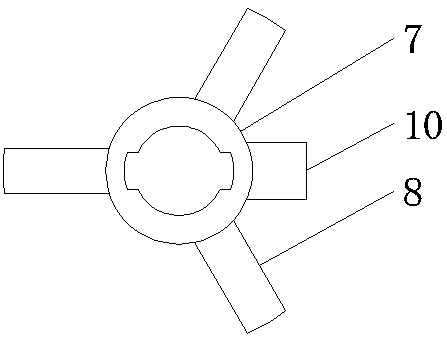

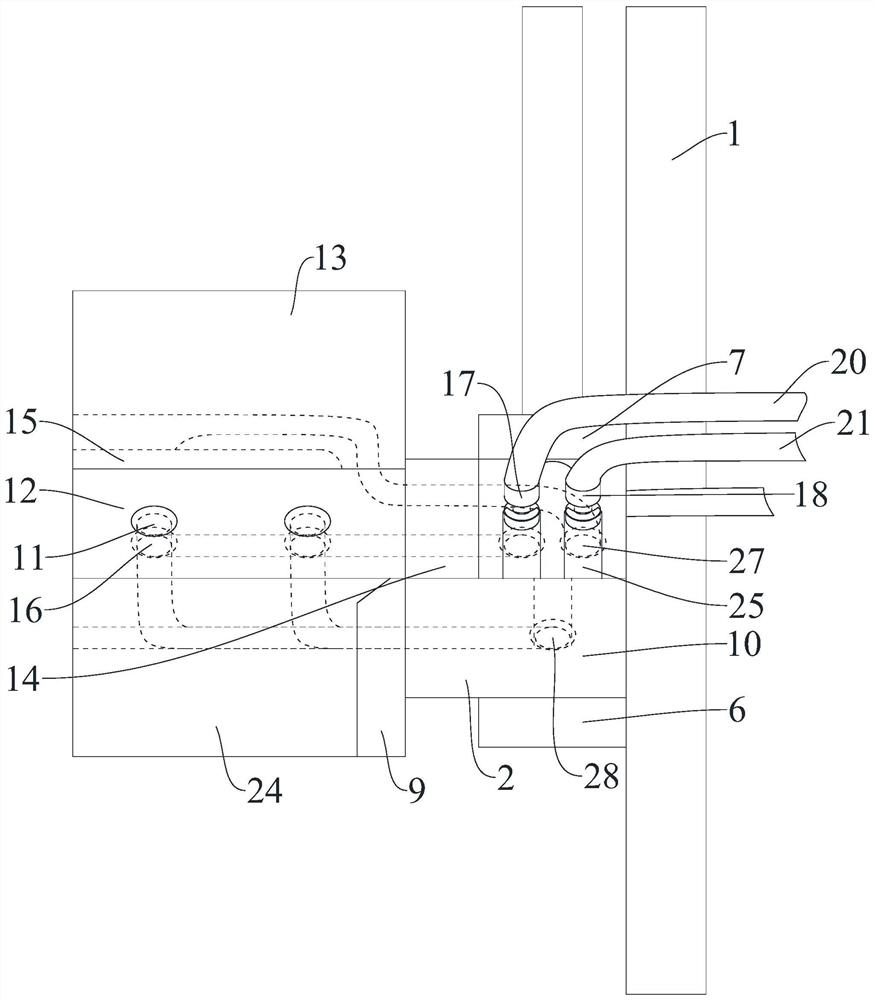

Metal ring quenching processing mechanism

The invention discloses a metal ring quenching processing mechanism, which comprises a quenching pool, wherein an annular processing groove is formed in the quenching pool; a quenching pipe is connected to the outside of the quenching pool; an elbow part is formed in the quenching pipe; a joint opening is formed in the end part of the quenching pipe; a locking block is arranged at the connecting position of the quenching pipe and the quenching pool; the locking block is butted with the quenching pool through a locking pin. According to the metal ring quenching processing mechanism, a to-be-processed metal ring can be mounted in the processing groove; the quenching pipe is connected with a quenching fire source through the joint opening; a fire source is continuously provided to the quenching pipe through the quenching fire source, so that the quenching treatment of the metal ring can be conveniently carried out.

Owner:胡俊

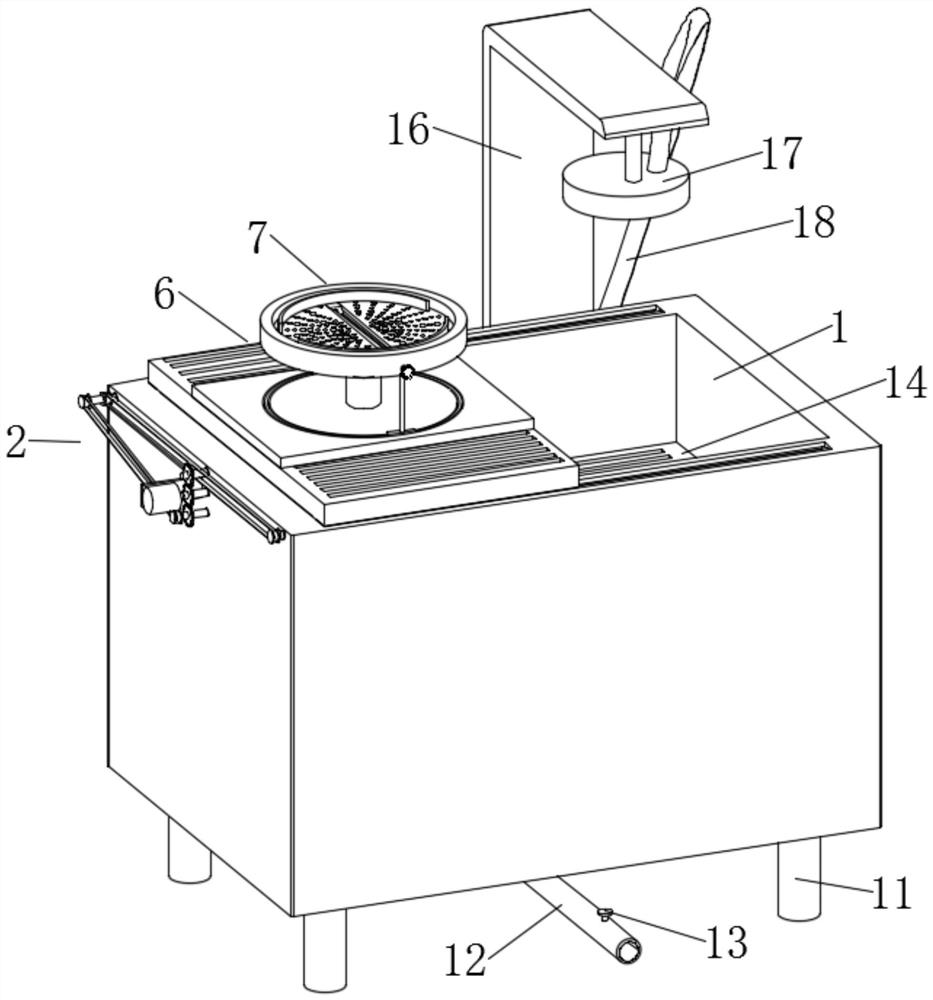

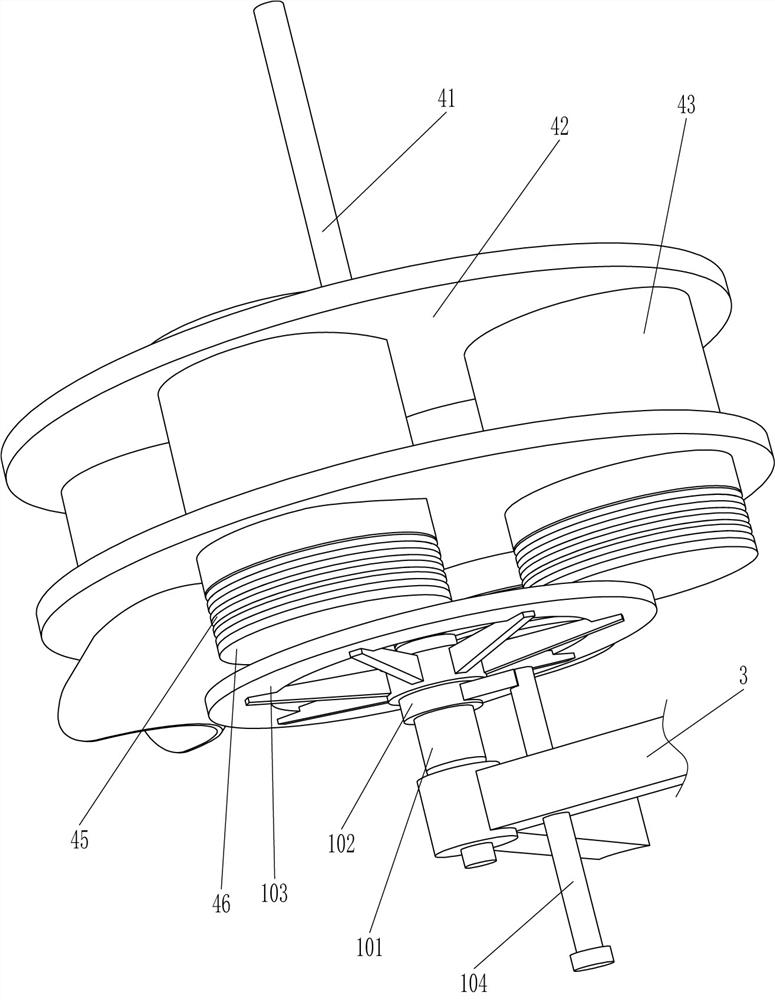

Sprocket gear quenching equipment

InactiveCN109136520AImprove work efficiencyEasy to adjustFurnace typesHeat treatment furnacesQuenchingSprocket

The invention relates to the technical field of gear processing and discloses sprocket gear quenching equipment. The equipment comprises a tank body in which cooling oil is added, and a heater, wherein a driving device is fixedly arranged at the bottom end of one side of the tank body; a sleeve provided with bosses on both sides is fixedly connected with the center of the bottom of the inner wallof the tank body; and groove rotating shafts are arranged at both sides, which are rotatably connected with a top end through two bearings, of both ends in the sleeve. The sprocket gear quenching equipment has the beneficial effects that through the cooperation of the rotating shafts, support plates, support frames and rotating wheels, object stages can be rotated; meanwhile, by utilizing a heater, the rotating shafts, a rotating disc, limiting cylinders and a driving wheel, a heat-treated gear can be cooled below the cooling oil level through the rotation of the rotating shafts and the othergears can be rotated to the position where the heater is arranged to be heated at the same time; and therefore, the other gears are heated while the gear is cooled at the same time, so that the gear can be conveniently quenched by the equipment and the work efficiency is improved.

Owner:耒阳市海天机械设备有限公司

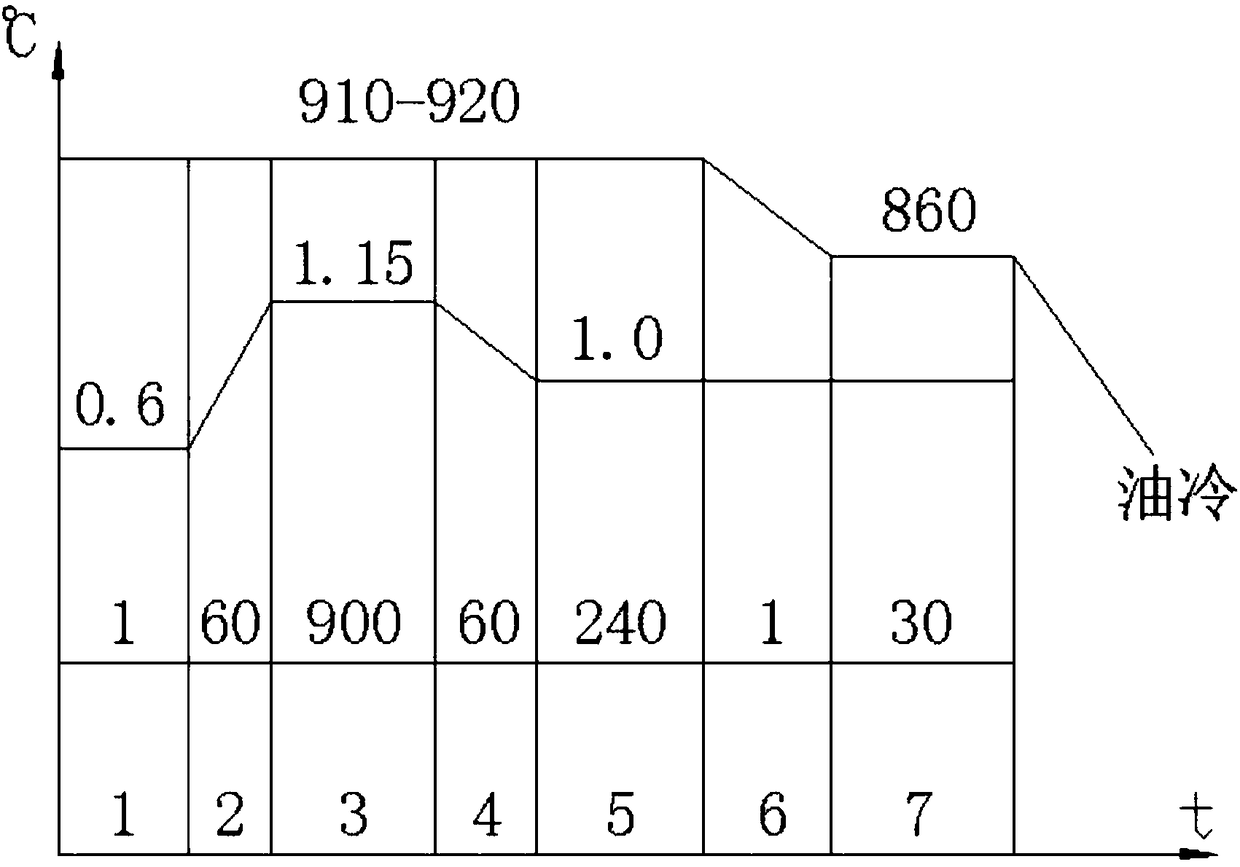

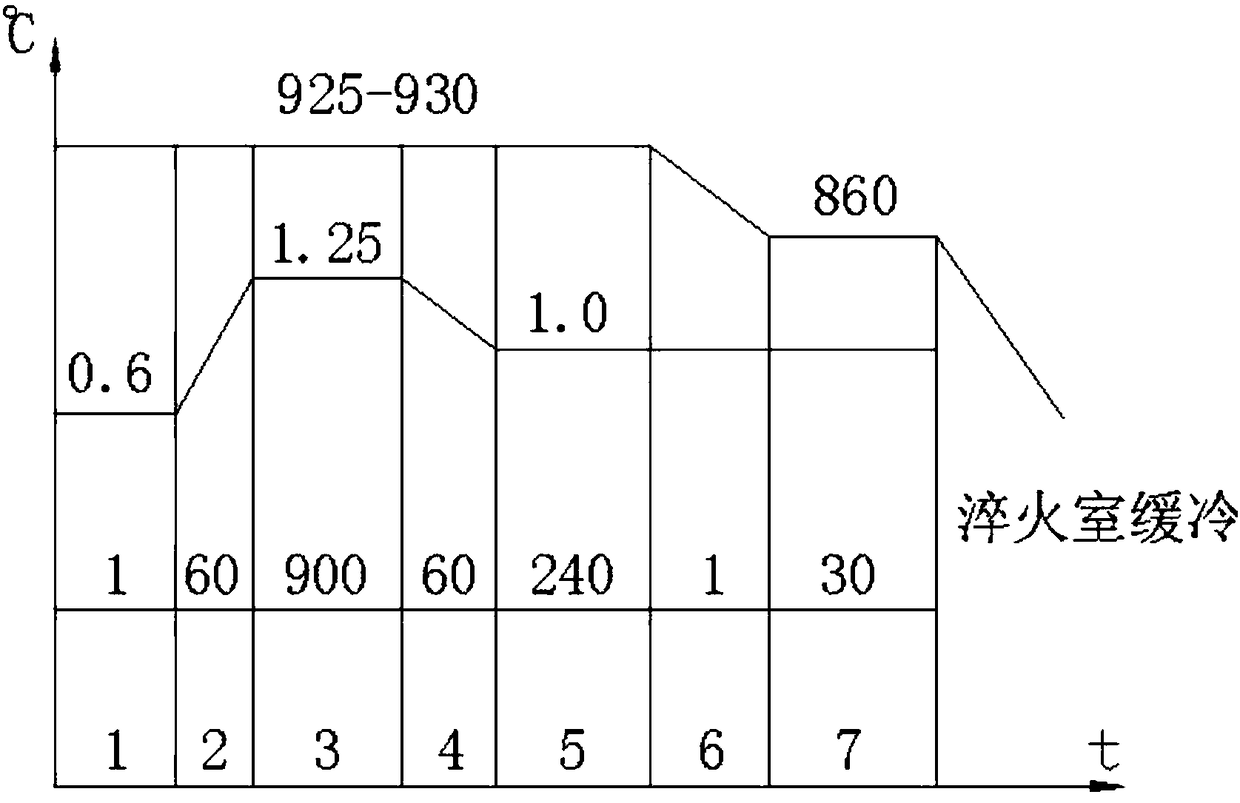

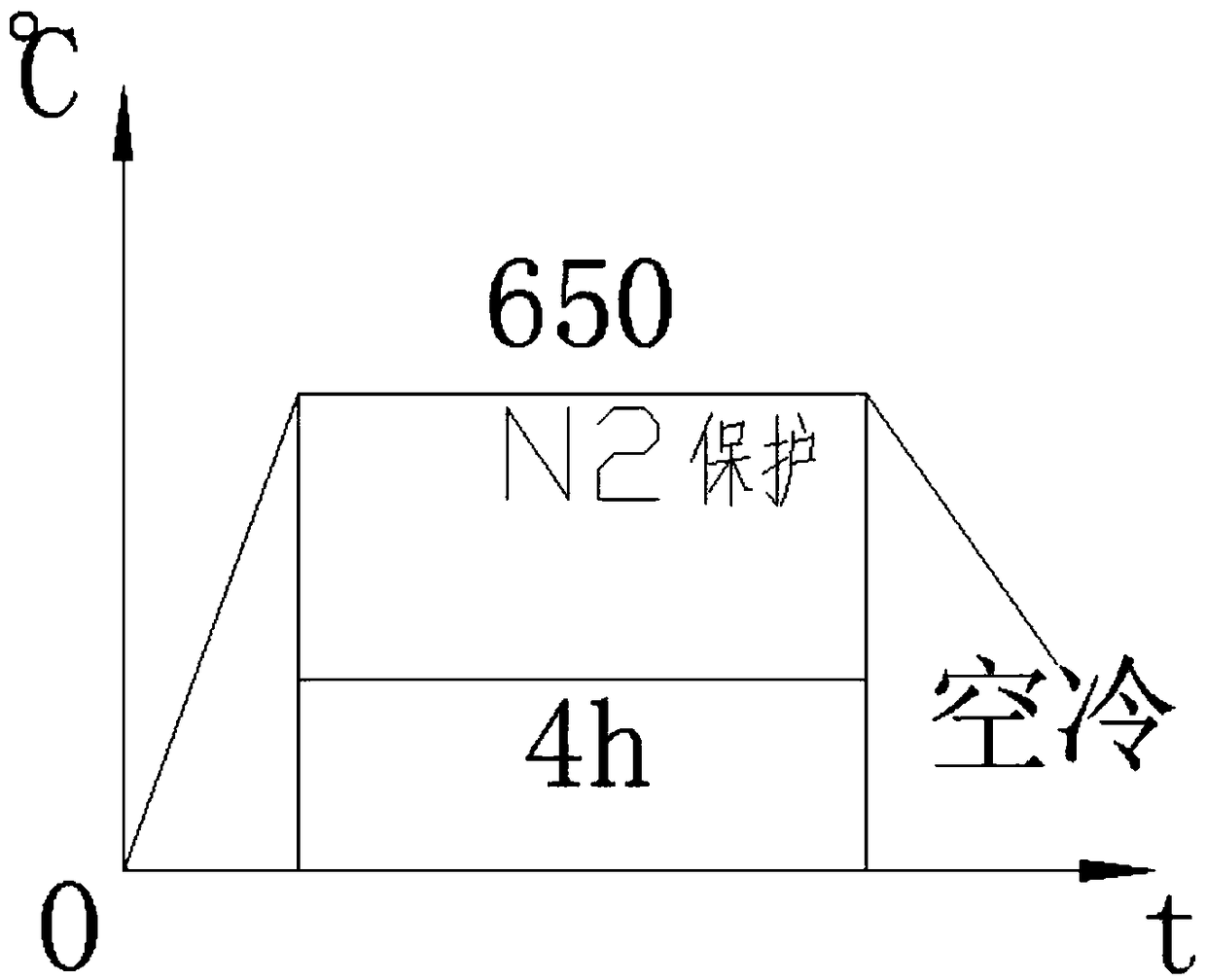

Heat treatment method for roller cone

InactiveCN108588388AExtended service lifeHeat treatment deformation is smallSolid state diffusion coatingFurnace typesCarbon potentialHardness

The invention provides a heat treatment method for a roller cone. The heat treatment method includes the following steps that (1) a roller cone pre-fabricated part is put in a furnace for carburizingtreatment, the temperature is controlled to be 925-930 DEG C, and the carburizing treatment includes a reinforcing carburizing period and a diffusion period; and after the diffusion period is over, aroller cone is cooled to 840-860 DEG C, subjected to slow cooling to 430-460 DEG C and then discharged out of the furnace; (2) the roller cone which is already subjected to carburizing treatment and slow cooling and discharged out of the furnace is subjected to high-temperature tempering treatment, the temperature is controlled to be 670-690 DEG C, tempering is performed for 10-14 hours under protection of N2, then the temperature is decreased to 430-460 DEG C, and the roller cone is discharged out of the furnace and subjected to air cooling; (3) the roller cone which is already subjected to high-temperature tempering treatment is subjected to quenching treatment, the temperature is controlled to be 850-870 DEG C, carbon potential is 0.3-0.5%, and after 100-140 minutes, oil cooling is performed till the temperature reaches 100-150 DEG C; and (4) the roller cone which is already subjected to quenching treatment is subjected to low-temperature tempering, the temperature is controlled tobe 220-230 DEG C, and after 10-15 hours, the roller cone is discharged out of the furnace and subjected to air cooling till the temperature reaches the indoor temperature. By means of the heat treatment method, deformation of inner holes of the roller cone is small, the effective carburized layer and hardness are uniform, and the heat treatment quality of the roller cone is greatly improved.

Owner:武钢中冶工业技术服务有限公司

A fluorescent oxygen nanosensor with mitochondrial targeting

InactiveCN103575717BGood biocompatibilityLong luminous lifeNanostructure manufactureFluorescence/phosphorescenceBiological bodyInterference resistance

The invention discloses a fluorescent oxygen nano sensor with cellular mitochondrion targeting. The nano sensor has the fluorescent service life sensitive to dissolved oxygen quantity, and can specifically target a mitochondrion in a cell. After the cell phagocytizes the oxygen nano sensor, variations of the dissolved oxygen quantity in a cytoplasm and the mitochondrion can be detected by a variation of the fluorescent service life of the nano sensor. The fluorescent oxygen nano sensor with the cellular mitochondrion targeting has the following characteristics that (1) a PLL (Phase Locked Loop) housing layer allows the sensor to have good organism compatibility; encapsulation allows a probe to have external interference resistance; (2) the mitochondrion targeting is good; (3) the oxygen sensitivity of the fluorescent service life is high; (4) the dissolved oxygen quantity in different positions in the cell can be detected.

Owner:BEIJING JIAOTONG UNIV

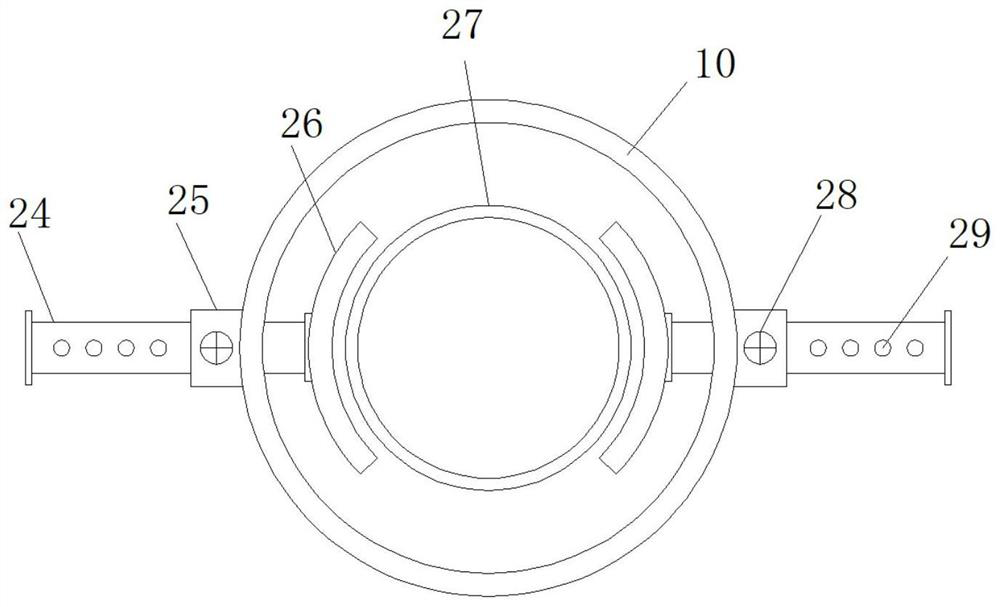

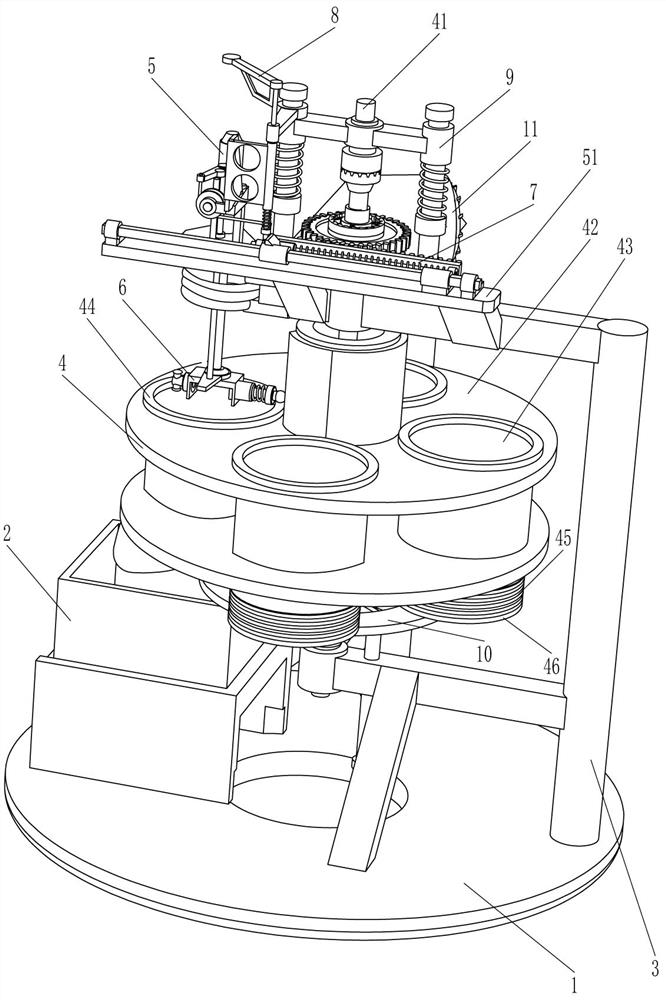

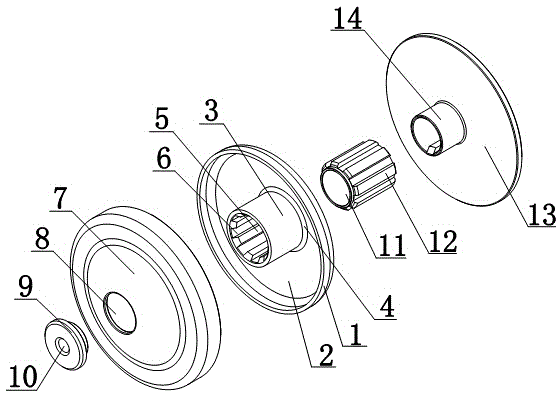

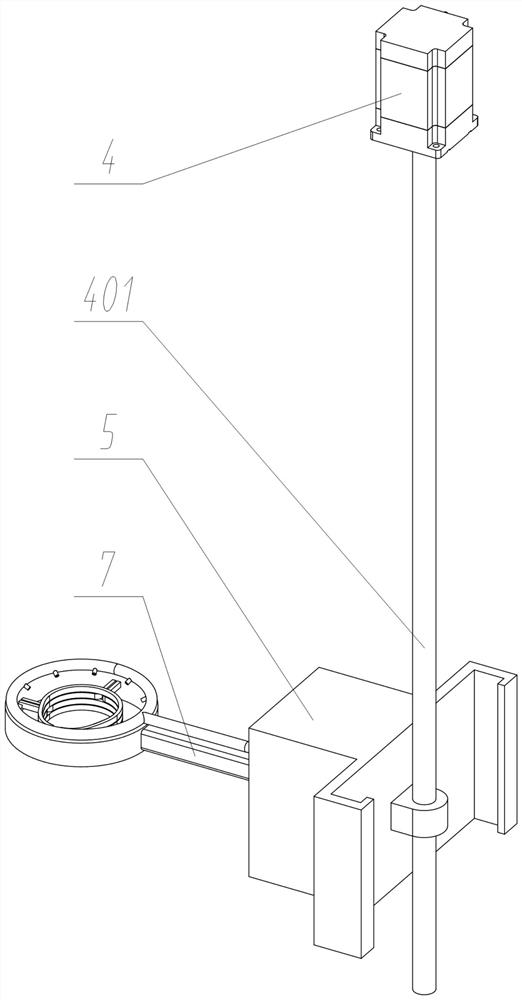

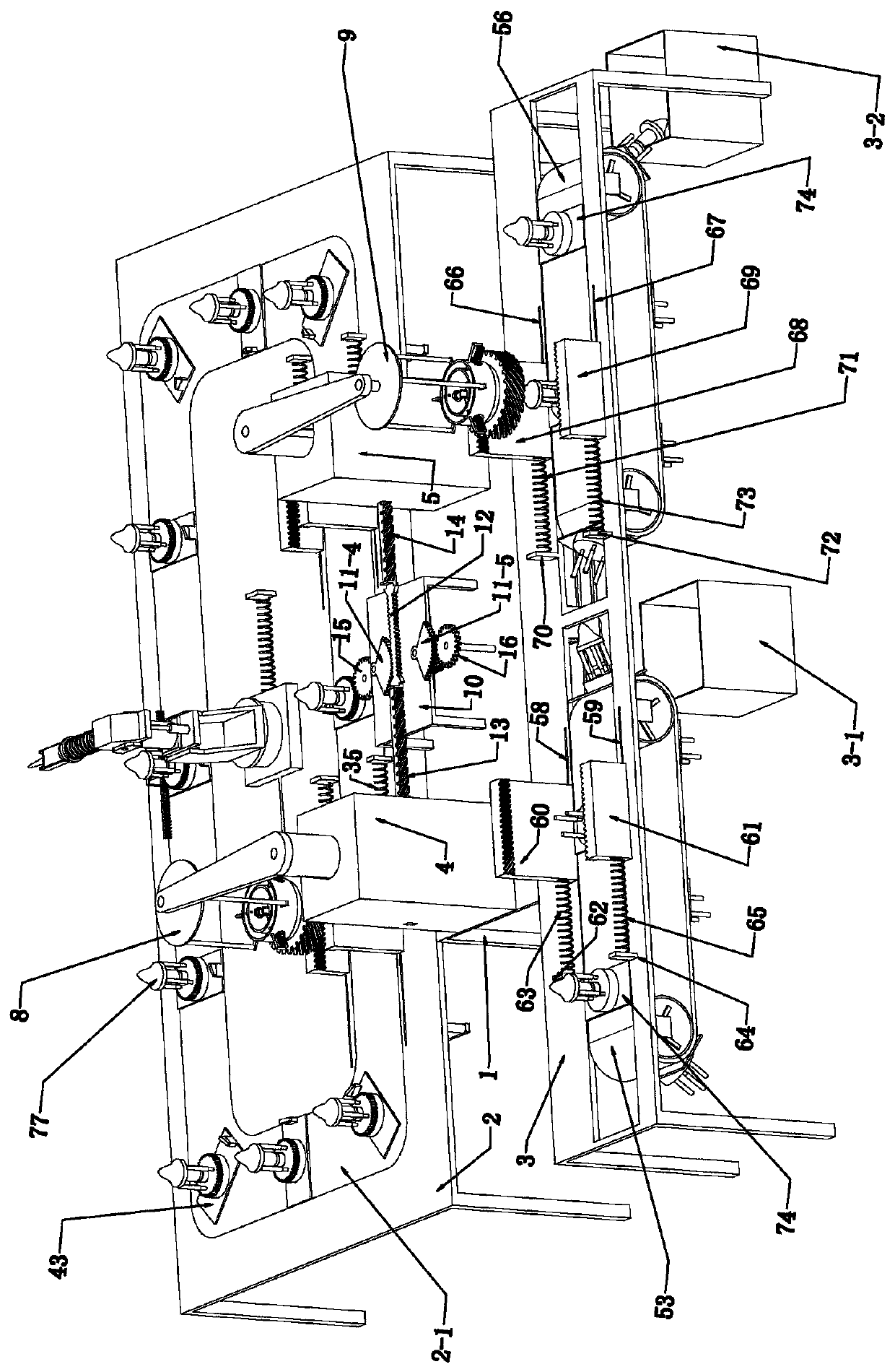

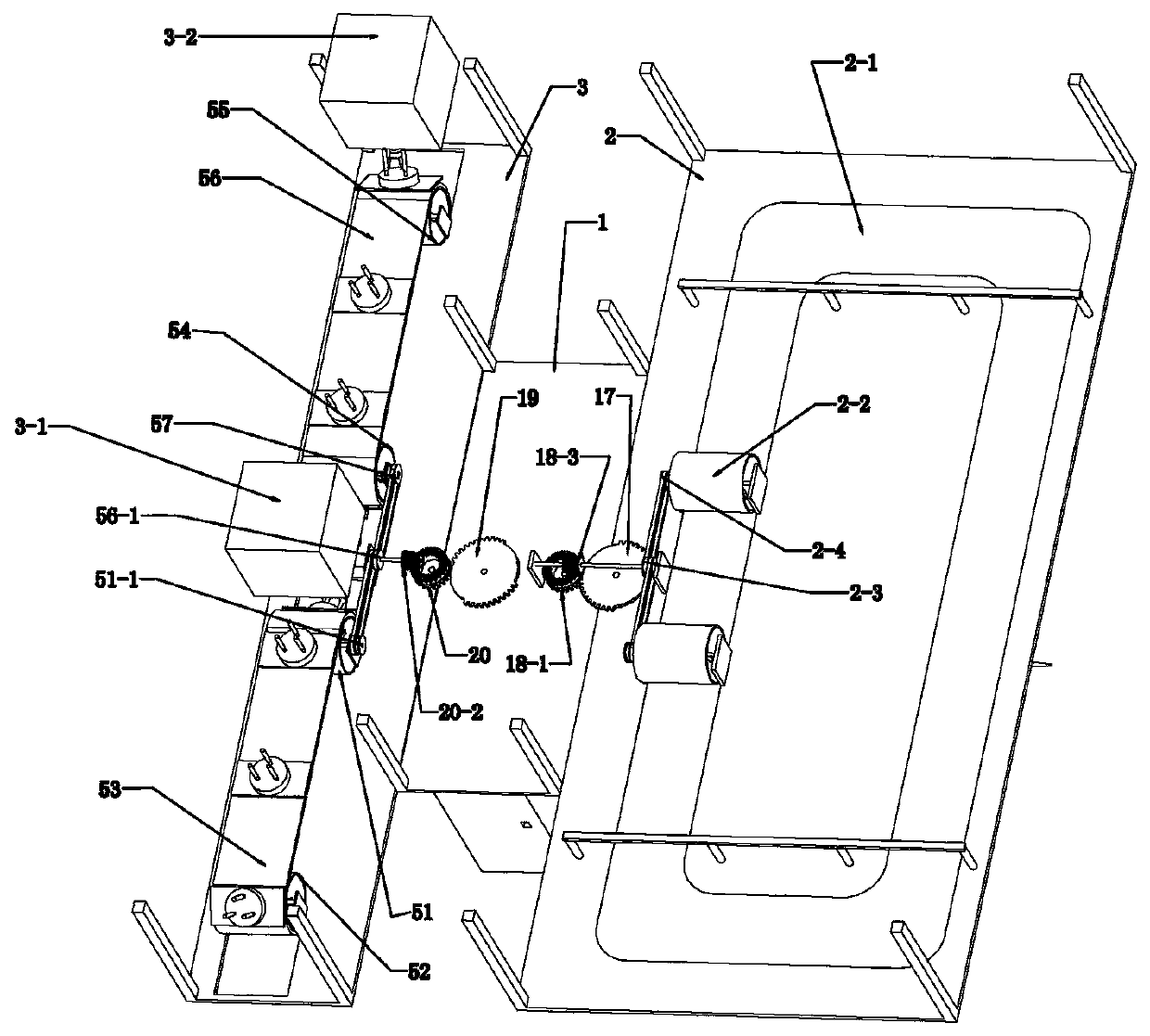

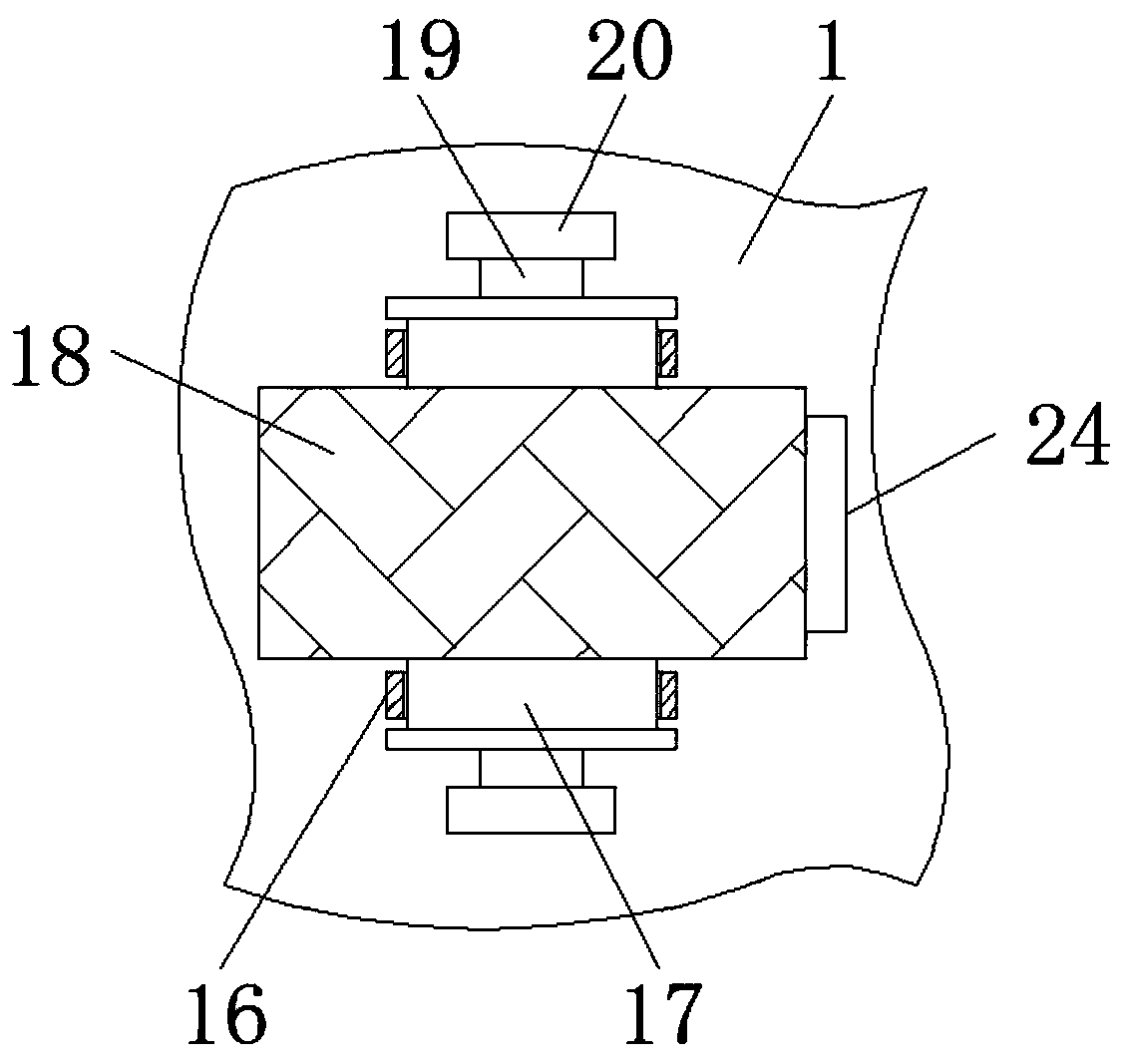

Quenching mechanism for machining slewing bearing

PendingCN114250346AEasy to fixImprove convenienceFurnace typesHeat treatment furnacesEngineeringSlewing bearing

The invention discloses a quenching mechanism for machining a slewing bearing, and particularly relates to the field of slewing bearing machining, the quenching mechanism comprises a collecting box, a blow-off pipe is fixedly mounted at the bottom end of the collecting box, a partition plate is fixedly mounted on the inner wall of the collecting box, and a connecting part is fixedly mounted on one side of the collecting box; a quenching disc is fixedly installed on the inner wall of the connecting part, a feeding mechanism is arranged on the face, away from the blow-off pipe, of the collecting box, a jacking mechanism is arranged on the surface of a partition plate, a rotating mechanism is arranged on the surface of the jacking mechanism, and a clamping mechanism is arranged on the surface of the rotating mechanism. The second rotating rod enables the material disc to rotate through the rotating disc, and the slewing bearing rotates synchronously along with the material disc, so that the quenching disc conducts quenching machining on the inner wall of the slewing bearing in the rotating state, quenching machining of the inner wall of the slewing bearing is conveniently completed, and then the convenience of quenching machining of the inner wall of the slewing bearing is effectively improved.

Owner:徐州健川机械制造有限公司

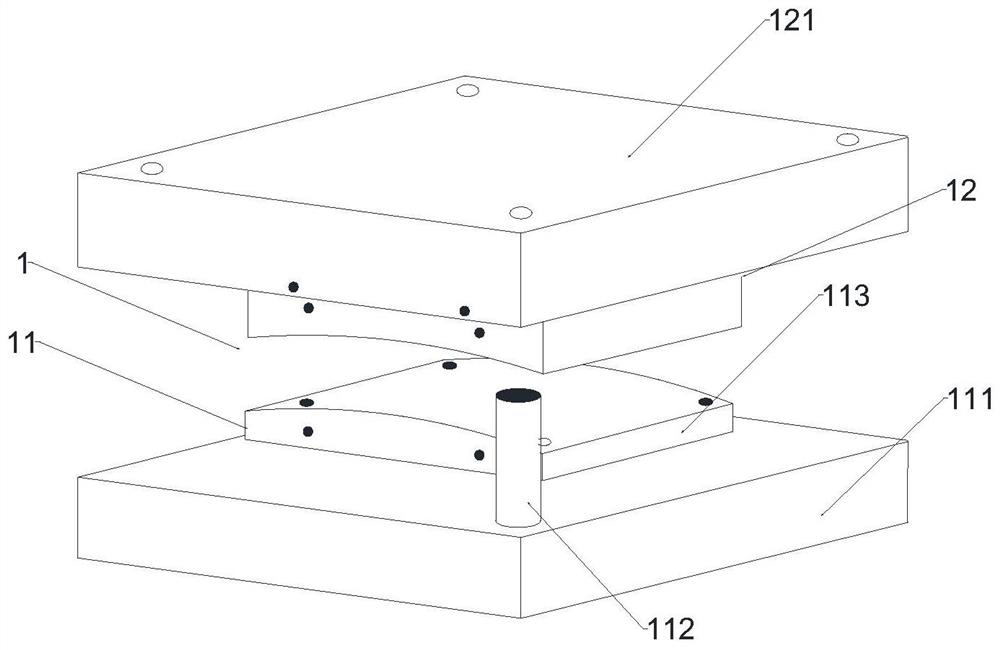

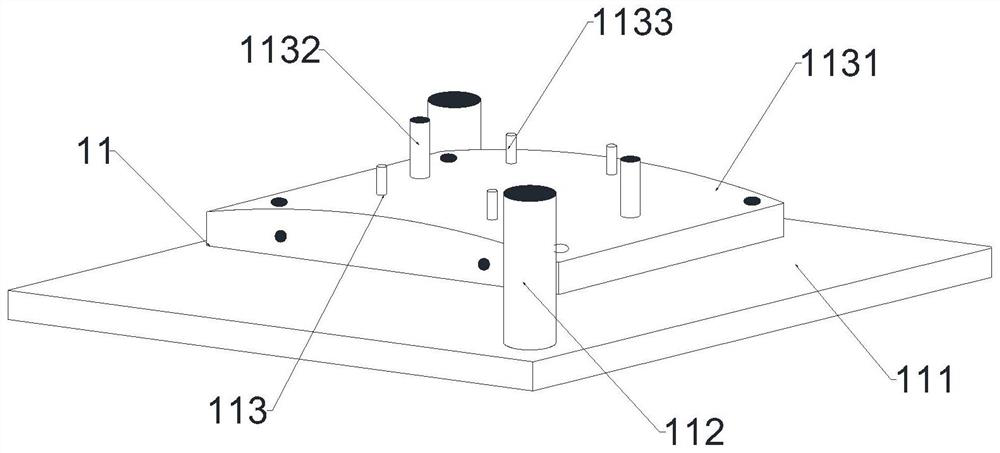

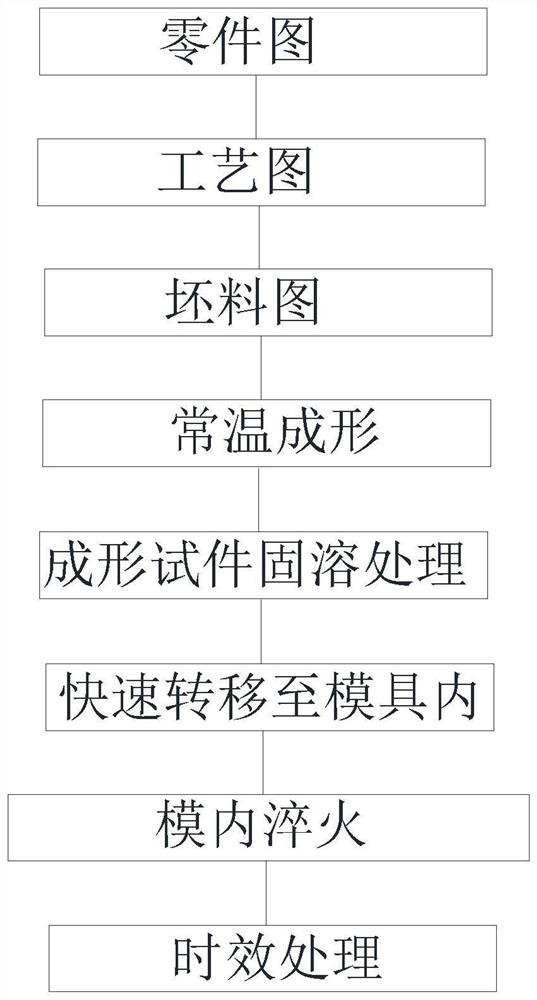

Quenching shape control method for flexible die of aluminum alloy curved surface part for spaceflight

PendingCN114107846ASimple structureReasonable designShaping toolsFurnace typesShape controlThermal deformation

The invention provides a quenching shape control method for a flexible mold of an aluminum alloy curved surface part for spaceflight. The quenching shape control method comprises the following steps: S1, obtaining a part plate blank according to a product structure; s2, a part is obtained through pre-drawing; s3, setting heat treatment parameter values; s4, carrying out solid solution heating and heat preservation on the preformed test piece; s5, after solid solution heating and heat preservation are completed, the sample is rapidly transferred to a quenching mold, the pre-formed sample is positioned, rapid mold closing is conducted, and forming is completed; s6, closing the mold, maintaining the pressure, and cooling (quenching) to obtain a test piece; and S7, taking out the test piece, and performing natural aging or artificial aging. According to the quenching shape control method for the flexible die of the aluminum alloy curved-surface part for spaceflight, the total time from rapidly taking out a plate blank from a furnace to before forming does not exceed 15 seconds by designing the flexible quenching die of the aluminum alloy curved-surface part in the forming process; and the problem of thermal deformation-quenching composite forming cracking of the spaceflight aluminum alloy curved surface piece with the large depth (27 mm) and the large curvature is solved, and therefore the product percent of pass is 100%.

Owner:TIANJIN AEROSPACE CHANGZHENG ROCKET MFGCO

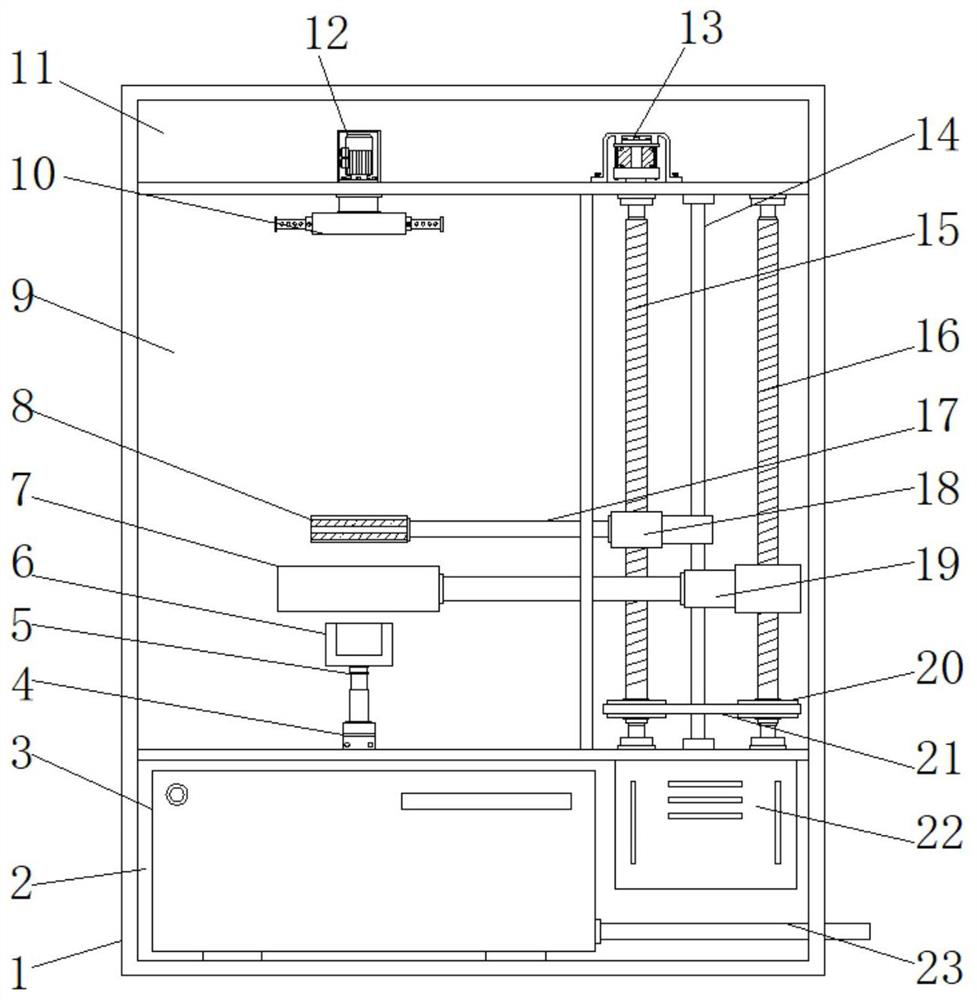

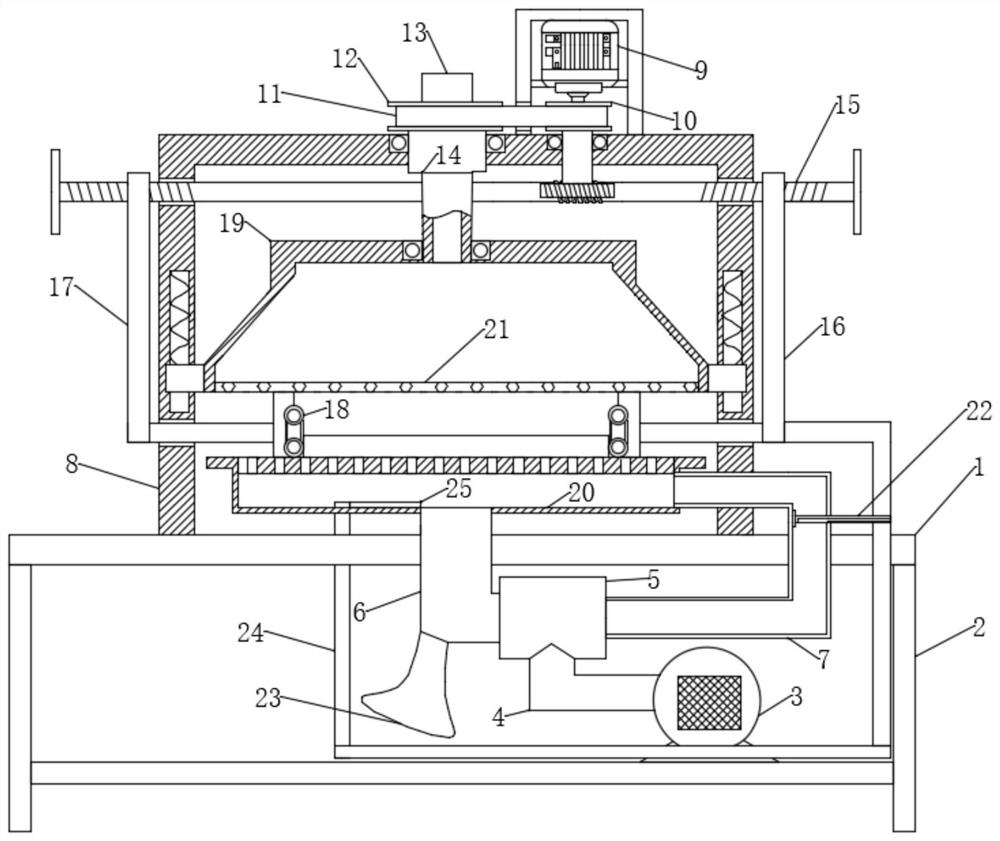

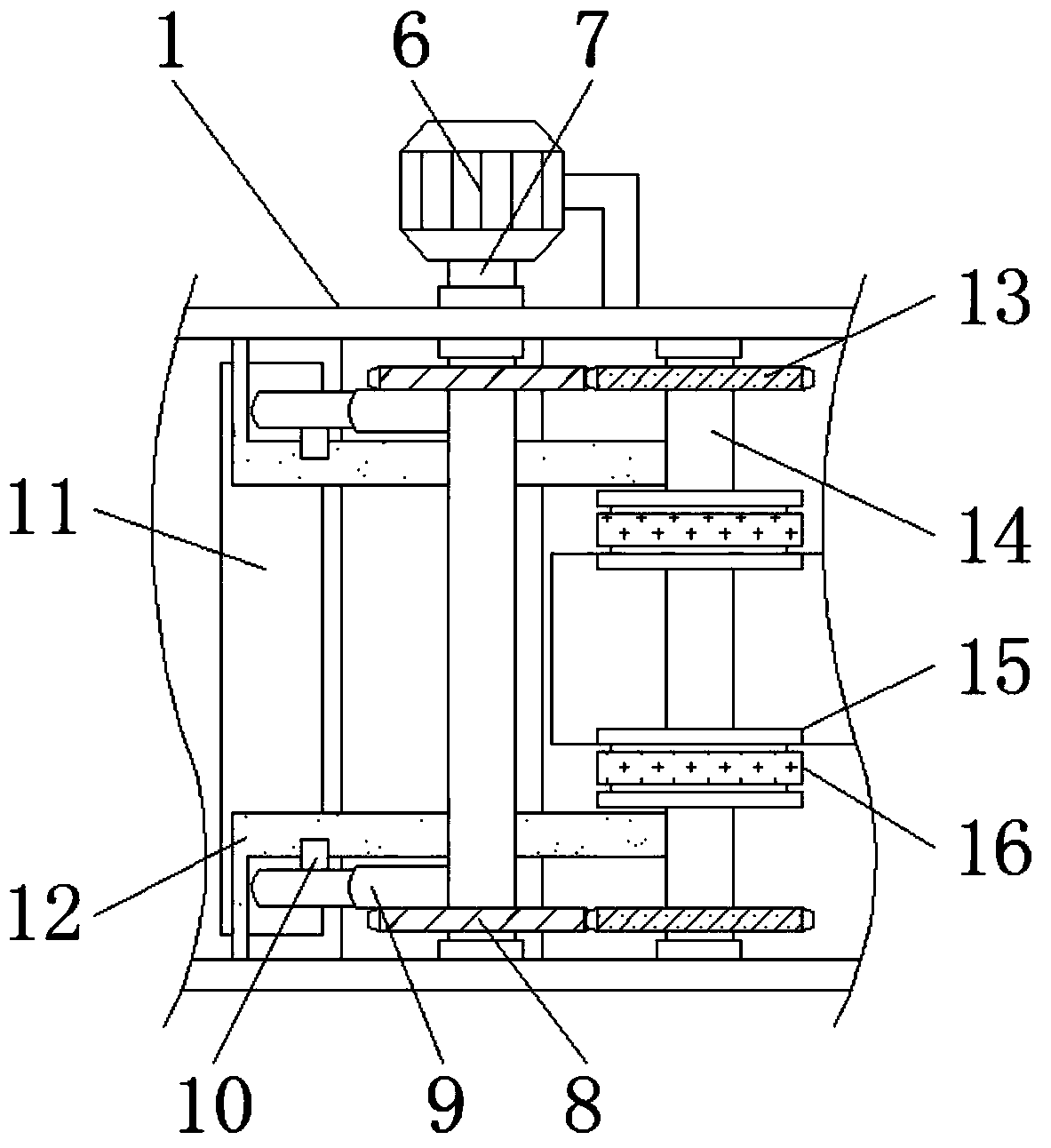

Heat treatment processing device for bearing ring processing

ActiveCN113502385AAffect the quenching speedAvoid affecting quenching efficiencyIncreasing energy efficiencyFurnace typesEngineeringMechanical engineering

The invention discloses a heat treatment processing device for bearing ring processing. The device comprises a first screw block, a heating wire, a first screw rod, a control box, a hollowed plate, a second screw block, a second mounting frame, a water suction pump, a second screw rod, a water pump and a conveying quenching device, the right side of the first screw block is fixedly connected to a connecting plate, the top end of the heating wire penetrates through the connecting plate to be fixedly connected to the bottom of a heater, the bottom of the first screw rod penetrates through the outer wall of the top end of the first mounting frame and the first screw block to extend into the first mounting frame, a signal receiver is mounted on the upper portion inside the control box through a partition plate, and a control panel is mounted under the signal receiver. According to the heat treatment processing device for bearing ring processing, heating wires are arranged, two bearing rings are quenched at the same time through the arrangement of the two heating wires, and therefore the situation that the quenching speed of the whole bearing rings is affected and the whole quenching efficiency is also affected due to the fact that the bearing rings are heated and quenched by a single heating wire is avoided.

Owner:浙江赛赛轴承有限公司

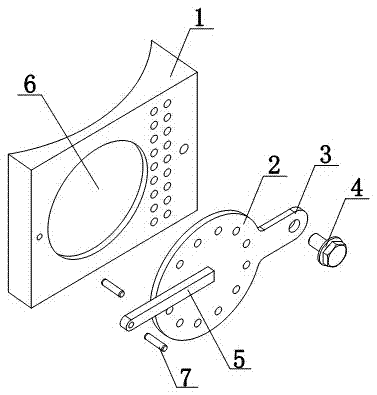

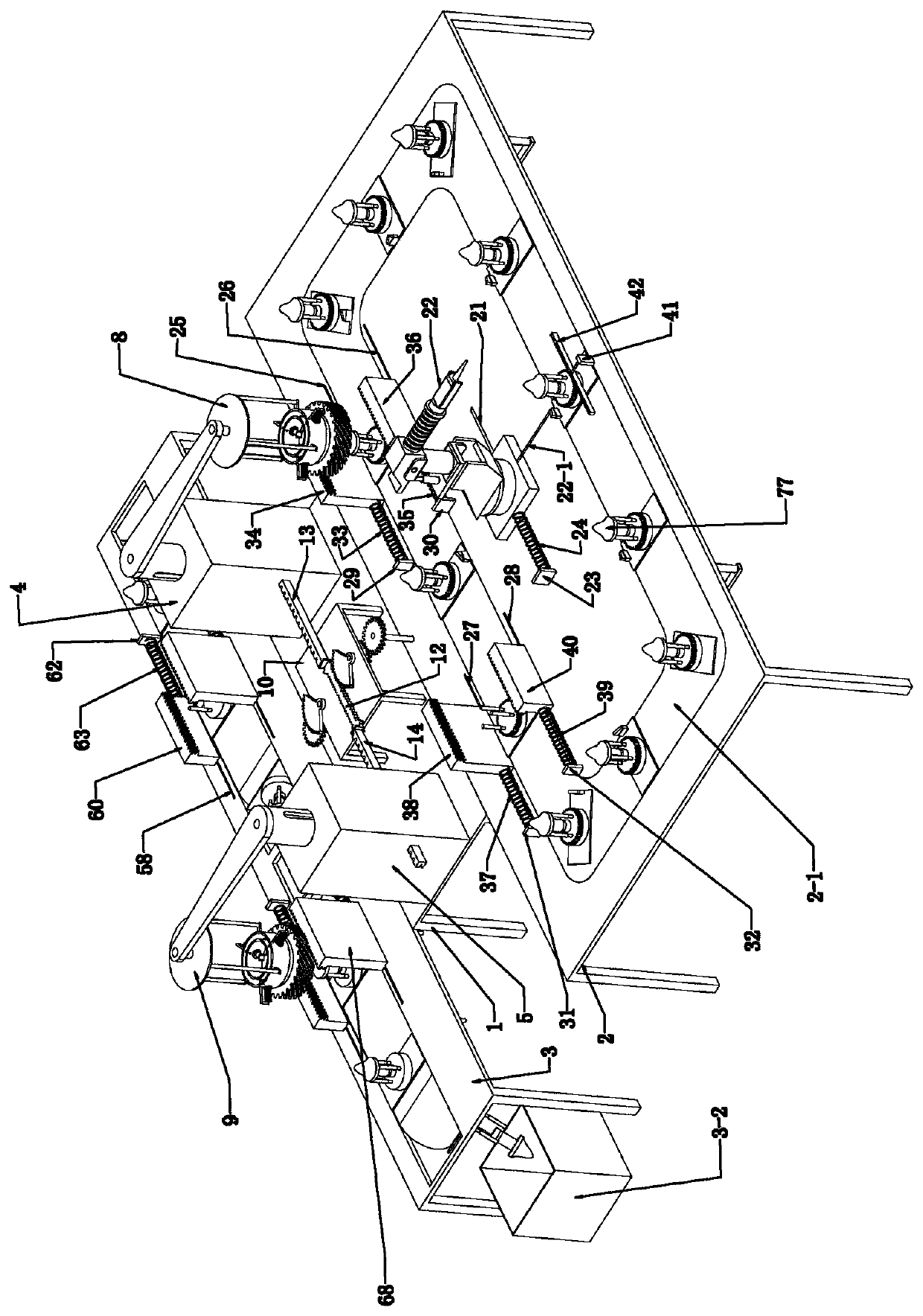

Five-axis linkage quenching machine tool carried with DSP and digital high-frequency power supply

PendingCN113789429AEasy to fixImprove stabilityIncreasing energy efficiencyHeat treatment process controlEngineeringMachine tool

The invention discloses a five-axis linkage quenching machine tool carried with a DSP and a digital high-frequency power supply. The five-axis linkage quenching machine tool comprises a machine tool body, a first cavity, a second cavity and a third cavity are formed in the machine tool body, a water collecting box is arranged in the first cavity, a cooling ring is arranged in the second cavity, and a heating ring is arranged above the cooling ring. According to the five-axis linkage quenching machine tool carried with the DSP and the digital high-frequency power supply, when cylindrical parts such as shafts are machined and quenched, the bottom ends of the cylindrical parts can be placed in the containing groove, then the top ends of the cylindrical parts are placed in a fixing ring, then adjusting rods on the two sides of the fixing ring are moved, the parts are clamped and fixed through clamping plates on the corresponding sides of the adjusting rods, and finally, fixing bolts are tightened and fixed, so that the parts are conveniently and stably fixed, the machine tool can conveniently carry out quenching machining on the parts, the quenching stability of the device is improved, and the problem that the parts needing to be quenched are inconvenient to fix is solved.

Owner:麦克斯威感应科技(江苏)有限公司

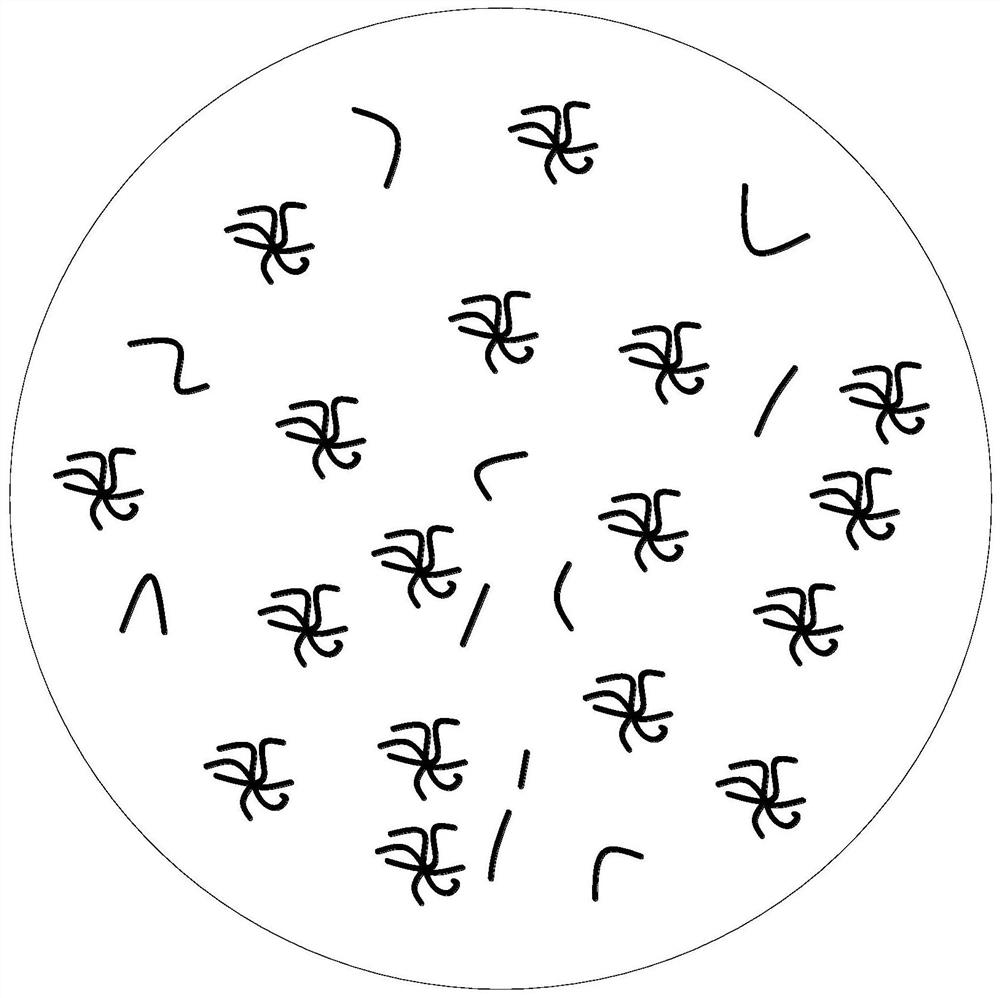

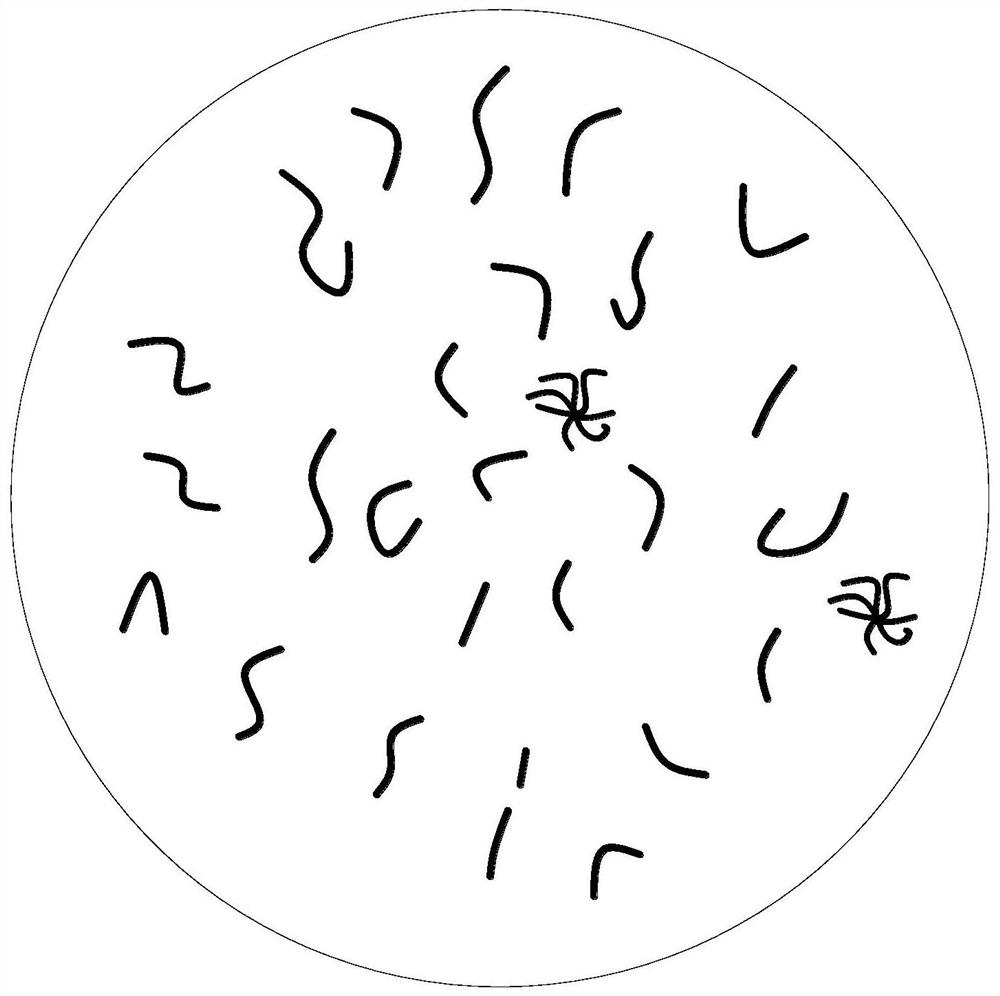

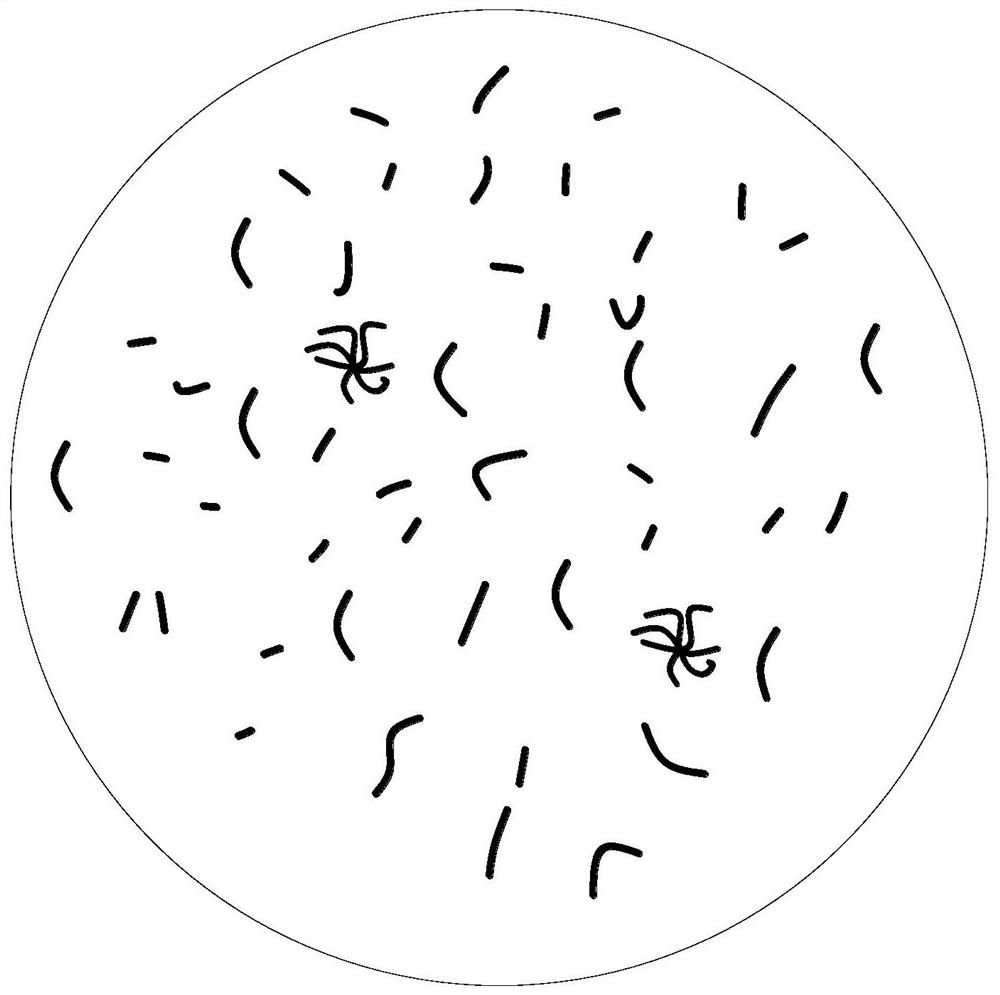

Casting method of high-matrix-hardness GM241 alloy gray iron

The invention discloses a casting method of high-matrix-hardness GM241 alloy gray iron. The casting method comprises the following steps that S1, the GM241 alloy gray iron is composed of 3.0%-3.2% of C, 1.6%-1.8% of Si, 0.9%-1.0% of Mn, less than 0.06% of P, less than 0.1% of S, 0.3%-0.5% of Cu, 0.10%-0.15% of Ni, 0.4%-0.5% of Mo and 0.4%-0.5% of Cr. According to the method, graphite is refined by prolonging the heat preservation time of molten iron and adopting a secondary inoculation method, the pearlite content is finally increased, the proportion of A-type graphite is increased, the length of the graphite is refined, the matrix hardness of a casting is improved, the matrix hardness is averagely improved by about 20 HB and is improved to 220-241 HB from original 197-220 HB, the casting is easier to quench, the quenching hardness reaches 52 HRC or above, and the casting is not prone to cracking in the quenching process.

Owner:南通虹冈铸钢有限公司

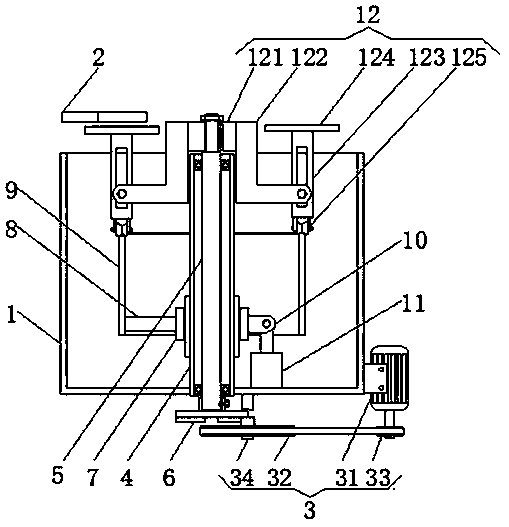

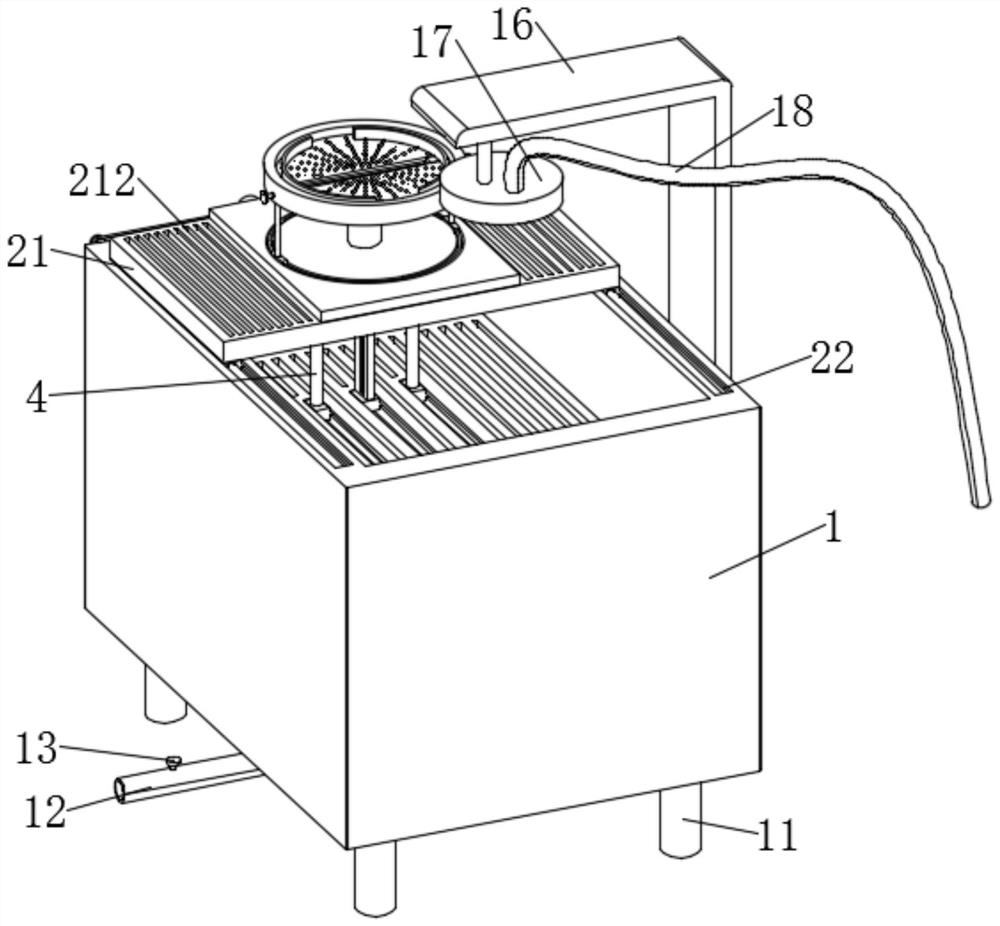

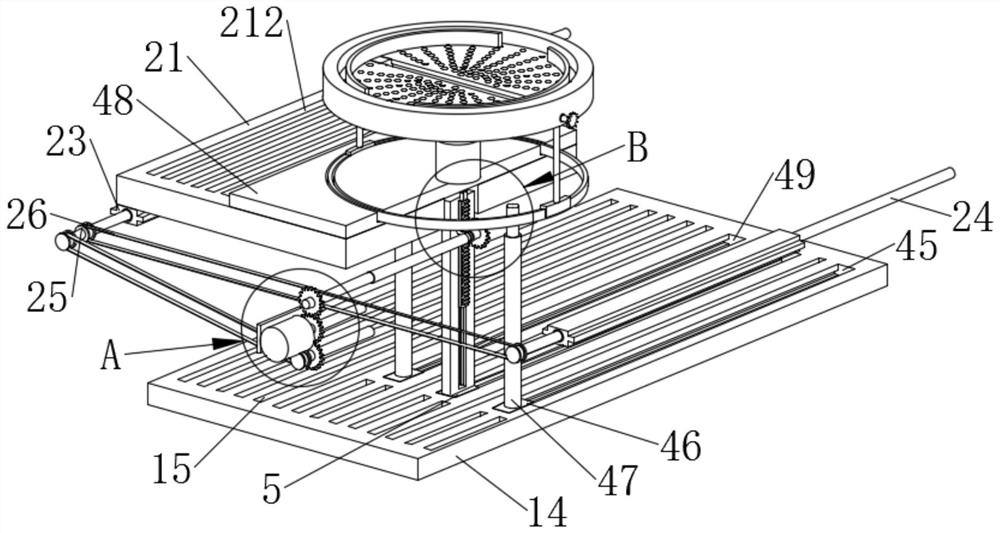

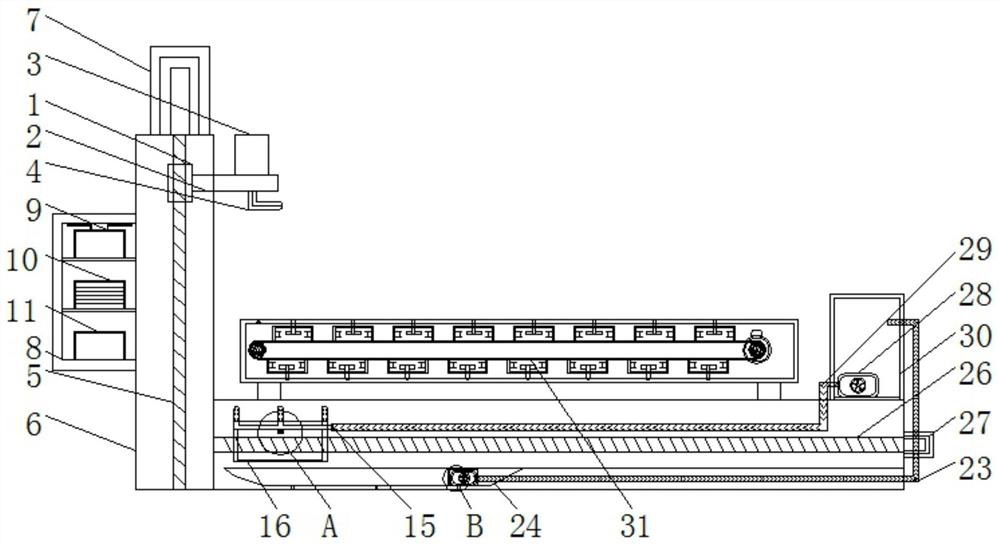

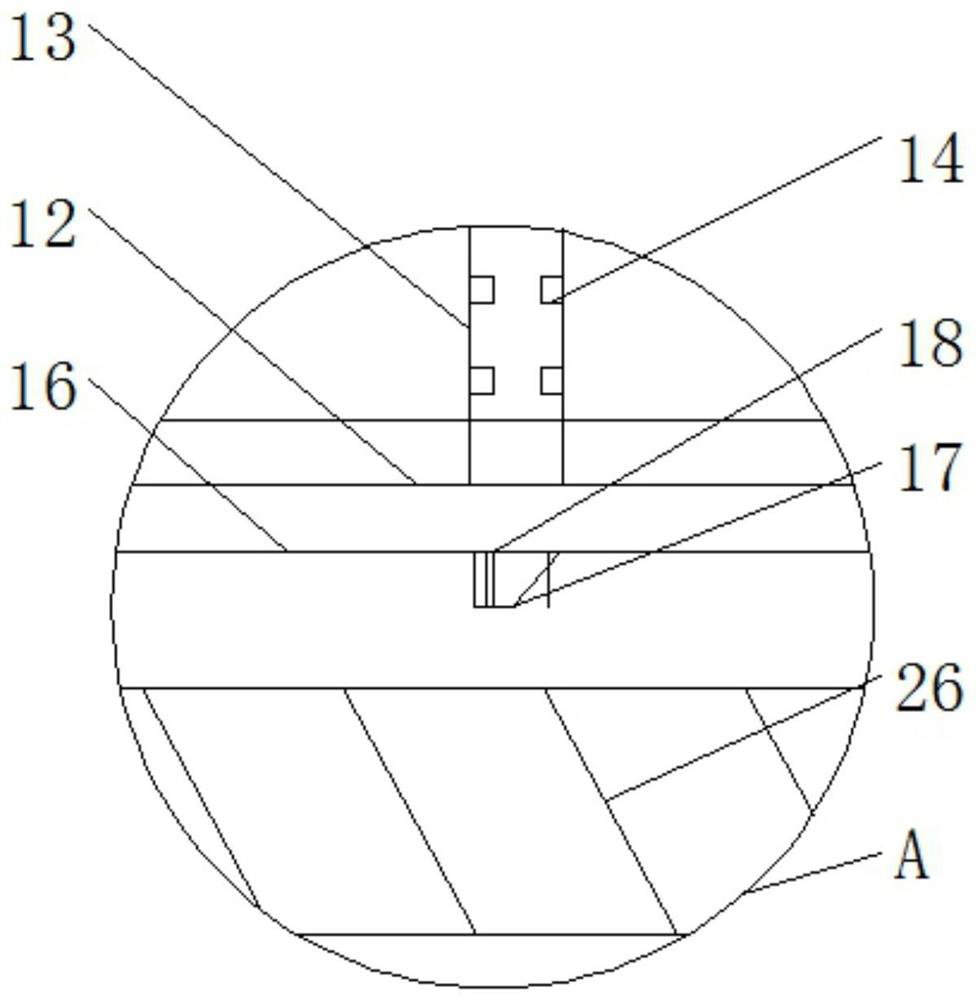

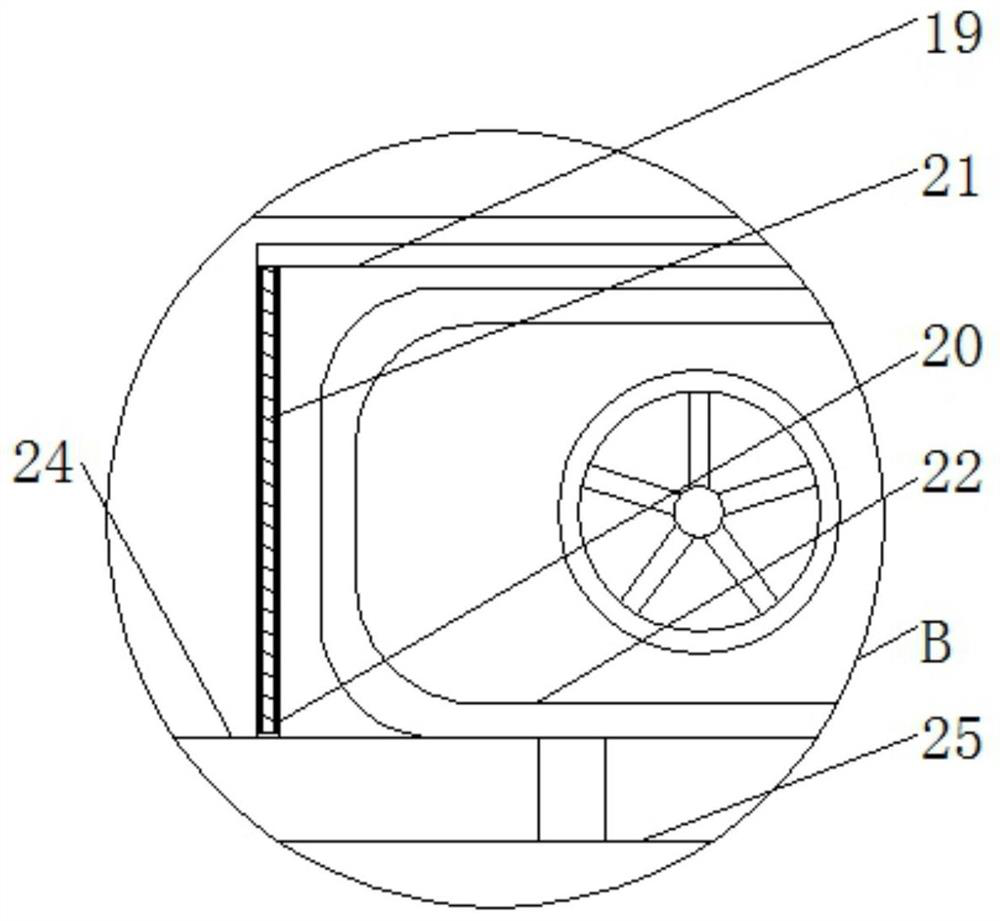

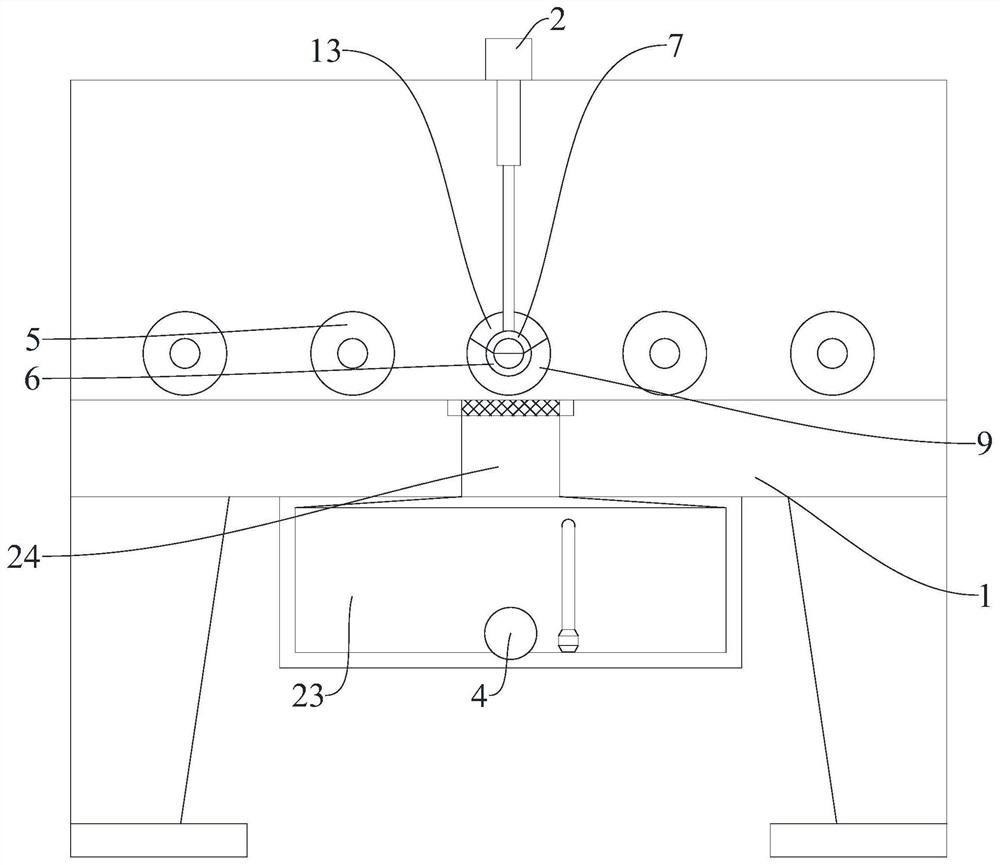

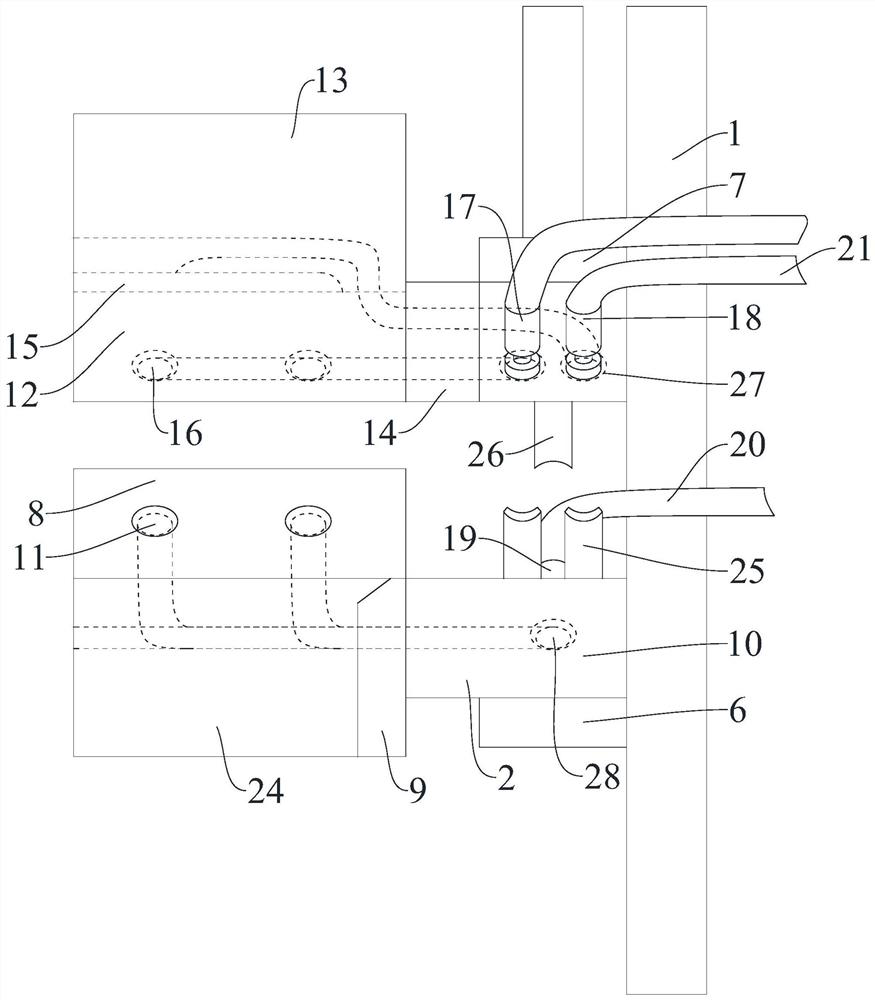

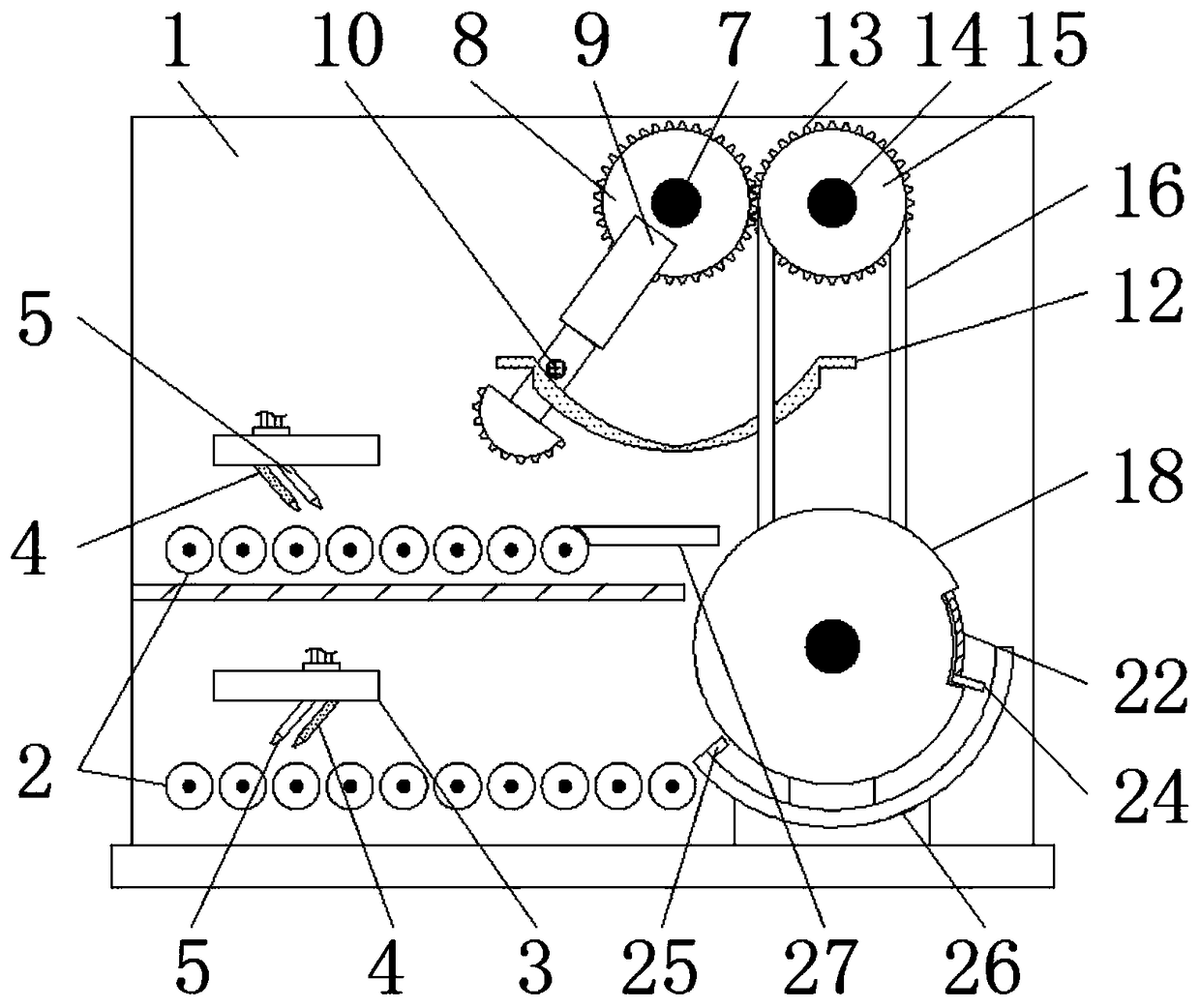

Integrated conveying and quenching mechanism for profile steel production

PendingCN113265521AOverall small sizeHigh degree of integrationFurnace typesHeat treatment furnacesAir pumpEngineering

The invention relates to the technical field of profile steel processing equipment, in particular to an integrated conveying and quenching mechanism for profile steel production. The integrated conveying and quenching mechanism comprises a main external machine frame, an electric lifter, an electric air pump and an electric liquid pump. The integrated conveying and quenching mechanism for profile steel production is provided with a lateral assembly support used for mounting a detachable bottom functional roller body and a lateral linkage support used for mounting a detachable top functional roller body, the lateral assembly support and the lateral linkage support are mounted in the main external machine frame, the lateral linkage support is driven by the electric lifter to ascend and descend, therefore, the detachable bottom functional roller body and the detachable top functional roller body are controlled to be separated and combined, quenching equipment is combined with a conveying mechanism, the size is more compact, and the integration degree is greatly improved; and the quenching equipment can be quickly combined to form conveying equipment, so that the functionality and the applicability are greatly enhanced.

Owner:东台市正祥金属制品有限公司

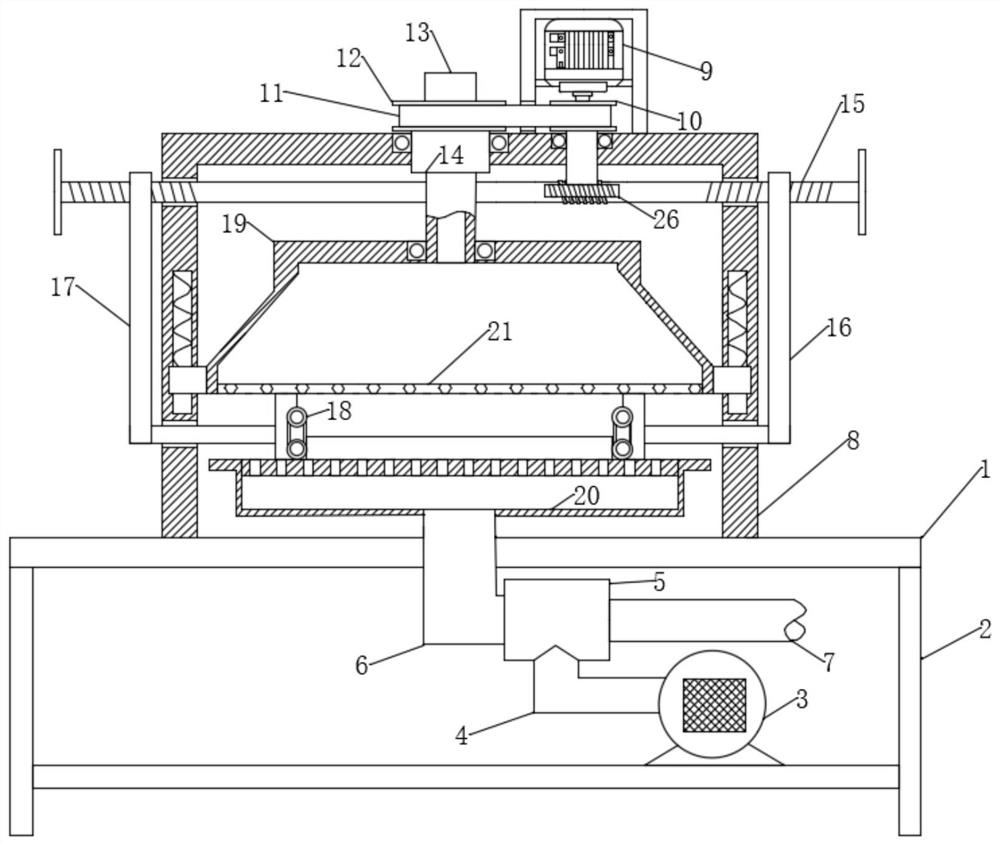

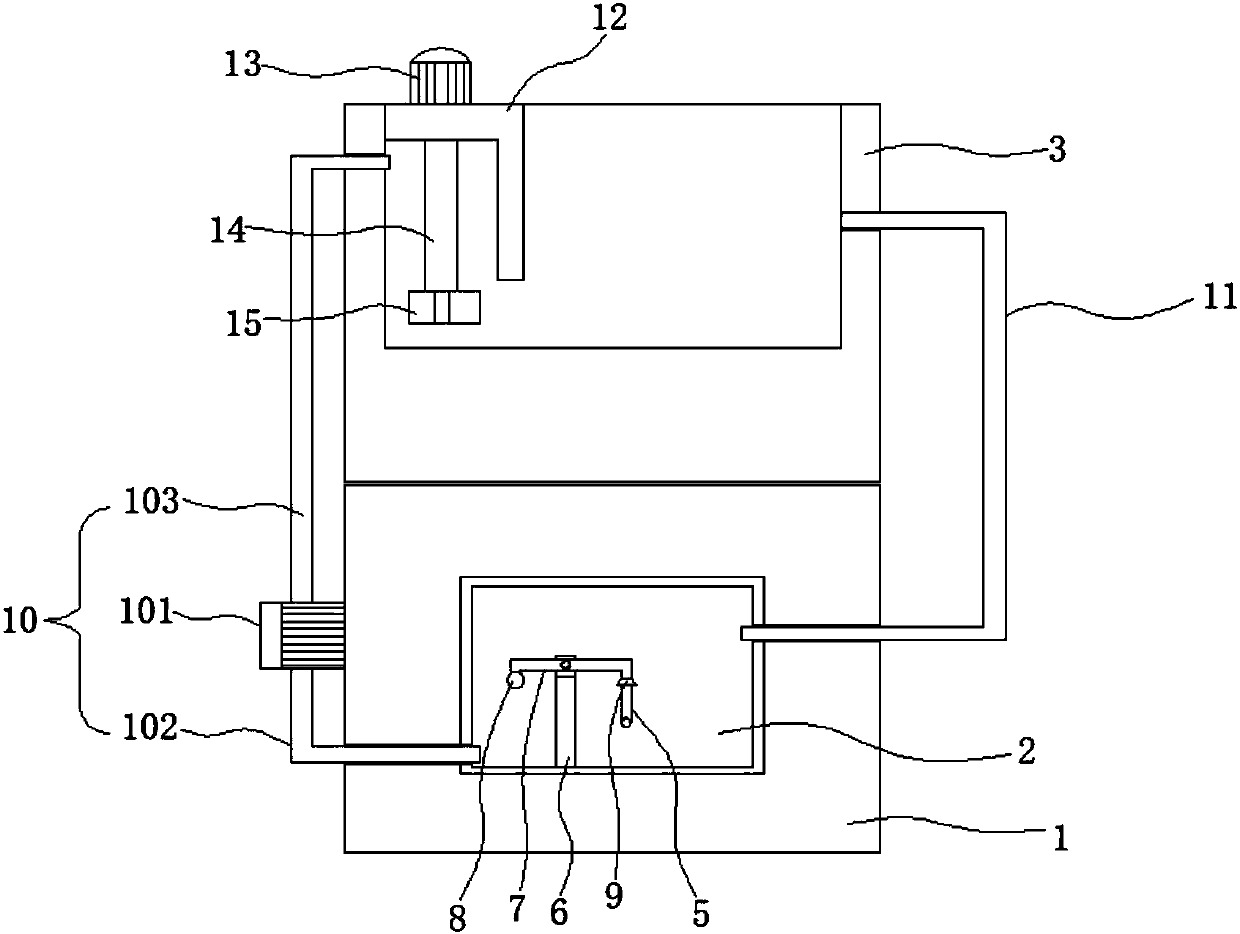

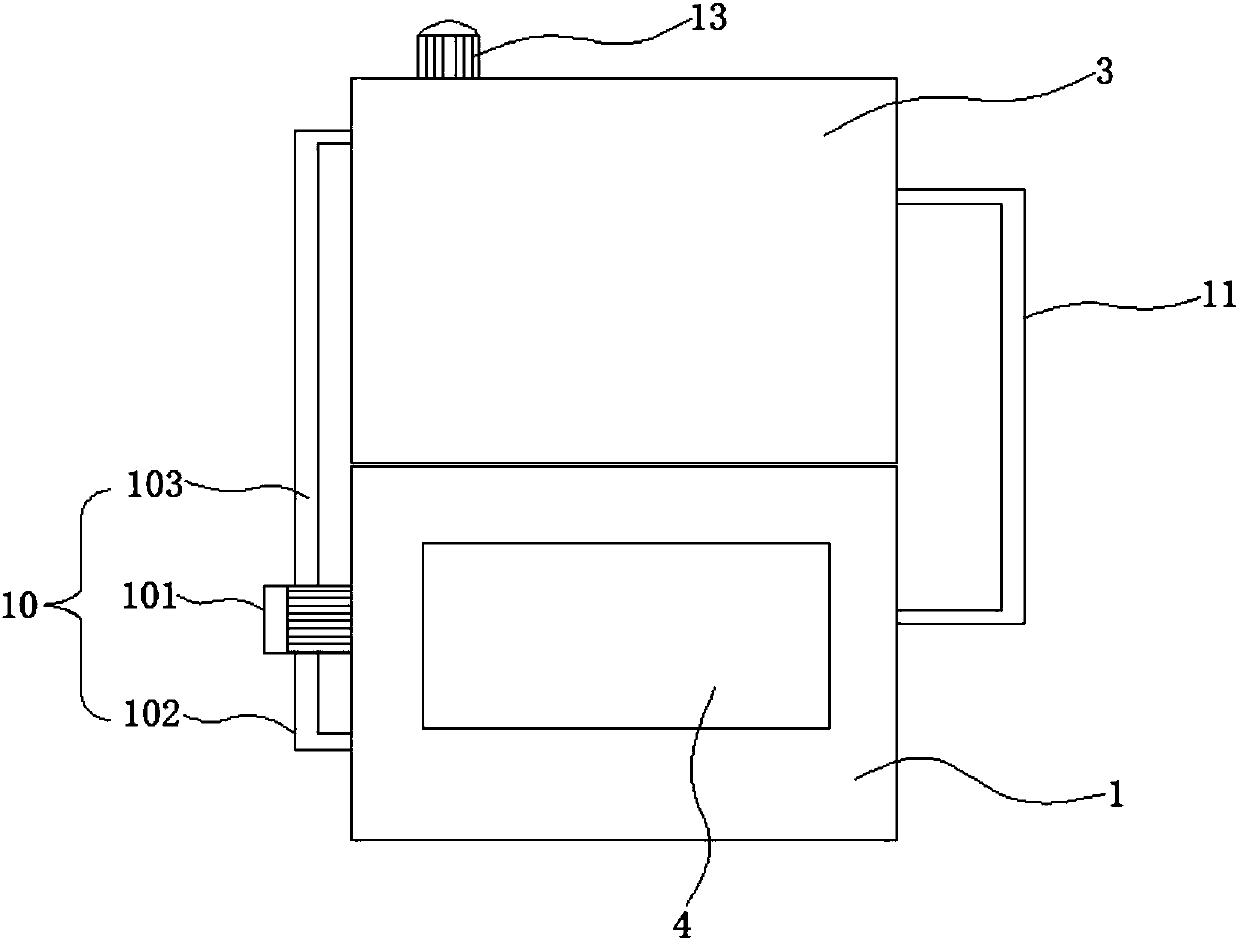

Intelligent quenching equipment for cast iron

PendingCN112779392AEasy to handleEasy to quenchIncreasing energy efficiencyQuenching devicesCast ironStructural engineering

The invention relates to quenching equipment, in particular to intelligent quenching equipment for cast iron. According to the intelligent quenching equipment for the cast iron, the liquid level of cooling liquid can be kept stable, quenched iron blocks can be automatically loosened, and the iron blocks can be air-dried. The intelligent quenching equipment for the cast iron comprises a base, a mounting plate, a replacement mechanism, a lifting mechanism and a clamping mechanism. A collecting frame is placed on the base. The mounting frame is arranged on the base. The replacement mechanism is rotationally arranged on the mounting frame. The lifting mechanism is arranged on the mounting frame. The clamping mechanism is arranged on the lifting mechanism. According to the intelligent quenching equipment for the cast iron, the iron blocks of different sizes are clamped through the clamping mechanism, then cooling liquid is contained through the replacing mechanism, then the iron blocks move up and down and the replacing mechanism intermittently rotates under the cooperation of the lifting mechanism and the driving mechanism, people can conveniently conduct quenching machining on the iron blocks, and the collecting frame can be used for collecting the quenched iron blocks.

Owner:王修涛

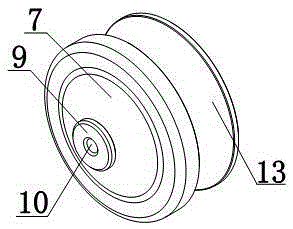

Sleeving device for screw quenching

InactiveCN108728624AEasy to installEasy to quenchFurnace typesHeat treatment furnacesButt jointEngineering

The invention discloses a sleeving device for screw quenching. The sleeving device for screw quenching comprises a mounting block, wherein the cross section of the mounting block is H-shaped; a butt-joint tube is arranged in the middle of the mounting block; one end of the butt-joint tube is connected with a butt-joint rod; a fixing block is arranged at an end of the butt-joint rod; a first butt-joint shaft is arranged between one end of the fixing block and one side of the mounting block; a second butt-joint shaft is arranged between the other end of the fixing block and the other side of themounting block; the second butt-joint shaft and the first butt-joint shaft are arranged in parallel; a mounting plate is arranged at the position of an outward surface of the fixing block; the periphery position of the mounting plate is provided with a sleeving groove and a magnetic attraction seat; the cross section of the magnetic attraction seat is semicircular; the magnetic attraction seat isattracted to the position of an outward surface of the mounting plate; the other end of the butt-joint tube is connected with another butt-joint tube; and the fixing block is connected with the mounting plate through a fixing bolt. The magnetic attraction seat can sleeve the outer peripheral surface of a screw and is attracted to the mounting plate, and therefore, the screw can be mounted firmly.

Owner:丁茂明

Glass plate tempering device utilizing contact method

InactiveCN113121098AFaster quenchingEasy and quick passGlass tempering apparatusMachineToughened glass

The invention belongs to the field of tempered glass preparation, and particularly relates to a glass plate tempering device utilizing a contact method, which comprises a base. A support plate is arranged on the lower side of the base, a shell is arranged at the upper end of the base below the support plate, and a movable nut is rotatably connected to the upper end in the shell. A second belt pulley is coaxially and fixedly connected to the upper end of the movable nut, a screw rod is engaged in the movable nut, a machine shell is rotatably connected to the lower end of the screw rod, a ventilation plate is arranged at the lower end of the machine shell, the two ends of the machine shell are slidably connected with the shell, a servo motor is fixedly connected to the portion, close to the upper end of the screw rod, of the shell, the output end of the servo motor is fixedly connected with a first belt wheel, the first belt wheel is sleeved with a belt, the other end of the belt is sleeved with a second belt wheel, the servo motor drives the first belt wheel to rotate, the first belt wheel adjusts the second belt wheel to rotate through the belt, the second belt wheel drives the movable nut to rotate, and the movable nut drives the machine shell ventilation plate to move downwards through the screw rod.

Owner:苏良旺

Quenching plate for cochlear amplifier

InactiveCN105420459AConvenient and strong setConvenient and quick quenching treatmentFurnace typesHeat treatment furnacesQuenchingButt joint

The invention discloses a quenching plate for a cochlear amplifier. The quenching plate comprises a plate body. A groove is formed in the plate body. A butt-joint pipe is arranged in the middle of the plate body. A butt-joint groove is formed in the axial direction of the butt-joint pipe. A plurality of clamping grooves arranged at equal intervals are formed in the inner surface of the butt-joint groove. A buckle plate is arranged on one side of the plate body. An opening is formed in the middle of the buckle plate and provided with a lock nut. A sleeving installation pipe is connected with the butt-joint groove in an inserted mode. A plurality of clamping protrusions arranged at equal intervals are arranged on the peripheral face of the sleeving installation pipe. The clamping protrusions are connected with the clamping grooves in a clamped mode. A buckle cap is arranged on the other side of the plate body. An object storing pipe is arranged on the surface facing inwards of the buckle cap. The object storing pipe is inserted into the sleeving installation pipe in the axial position of the sleeving installation pipe. An object storing groove is formed in the object storing pipe. According to the quenching plate, the cochlear amplifier can be conveniently sleeved and installed firmly, and the rapid quenching treatment of the cochlear amplifier can be conducted more conveniently.

Owner:岳文智

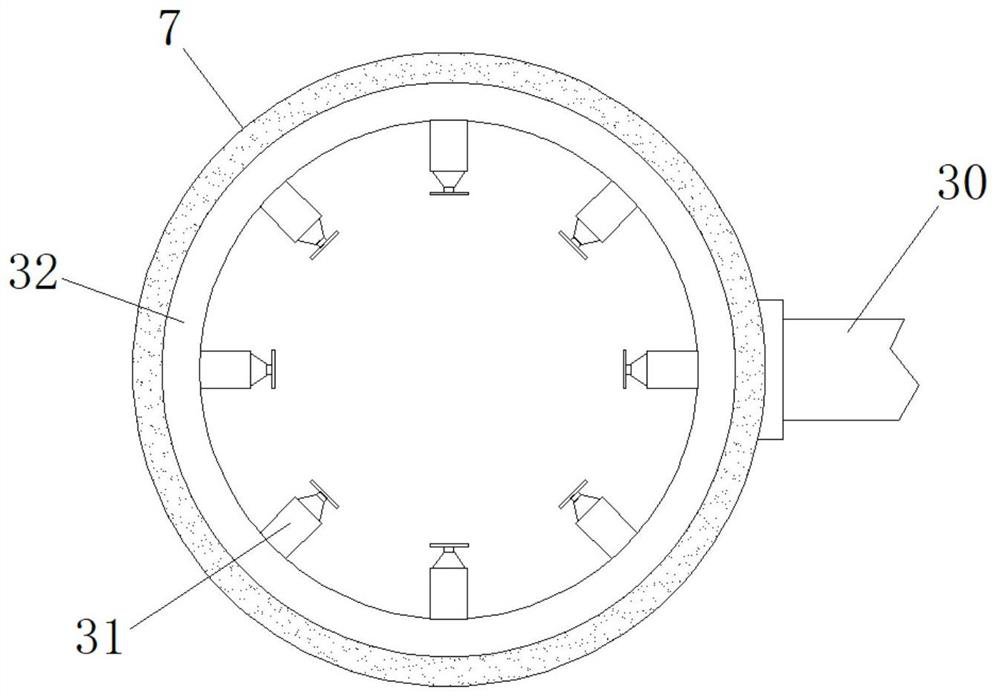

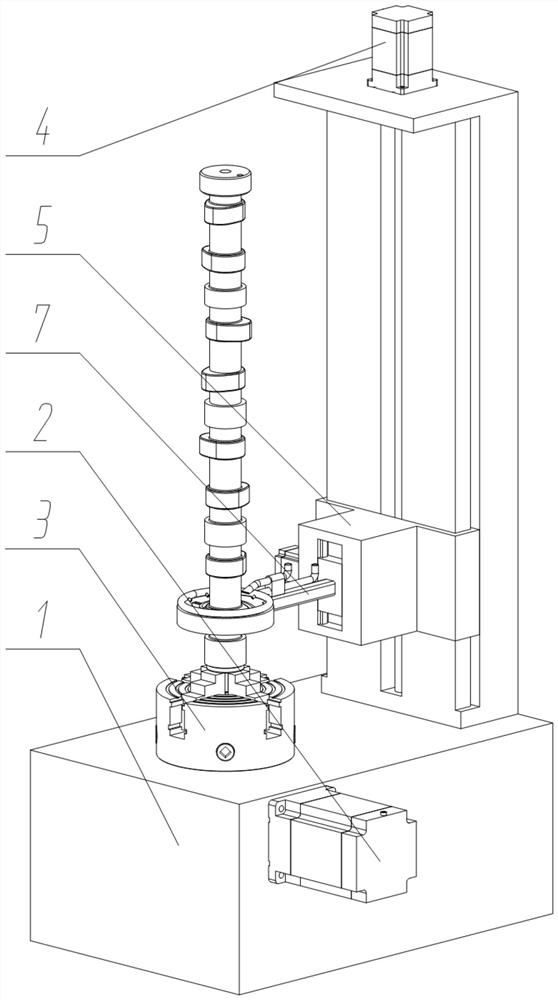

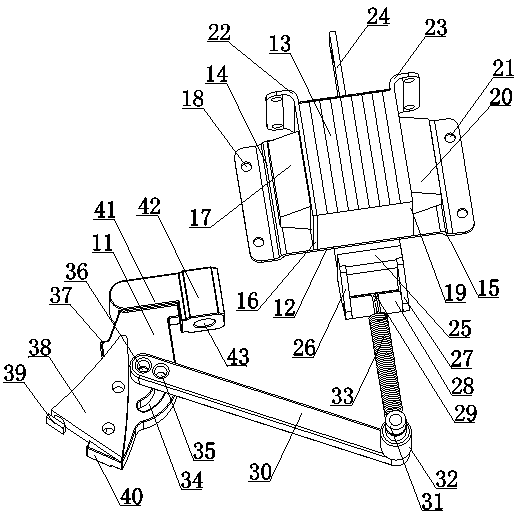

Special camshaft high-frequency quenching device

ActiveCN113088665AAchieve rotationEasy to quenchIncreasing energy efficiencyFurnace typesEngineeringMachining

The invention discloses a special camshaft high-frequency quenching device, and relates to the technical field of heat treatment equipment. The problems that during quenching machining of an existing camshaft, an existing induction coil is provided with an opening, during heating, opening heating unevenness, burning, cracking, hardness unevenness, quenching layer depth unevenness and the like are prone to happening, cracking is prone to happening, and the product quality is influenced are solved. The special camshaft high-frequency quenching device comprises an installing base, wherein a set of camshaft rotation drive pieces are fixedly connected to the lower portion of the front end face of the installing base; a set of lifting drive pieces are fixedly connected to the top of the installing base; a set of lifting sliding bases are in sliding connection to the left side of the installing base; and a set of slippage drive pieces are fixedly connected to the rear end faces of the lifting sliding bases. The special camshaft high-frequency quenching device solves the problems of burning, cracking, hardness unevenness, quenching layer depth unevenness and the like existing in the heat treatment process, the quality of the camshaft is improved, oxidation residues on the surface of a part are cleaned away, and the machining quality of the part is improved.

Owner:十堰宏兆汽配实业有限公司

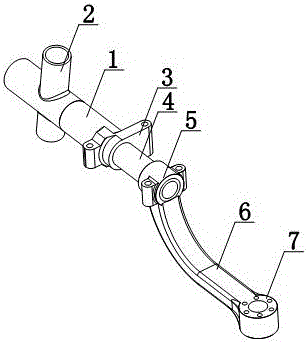

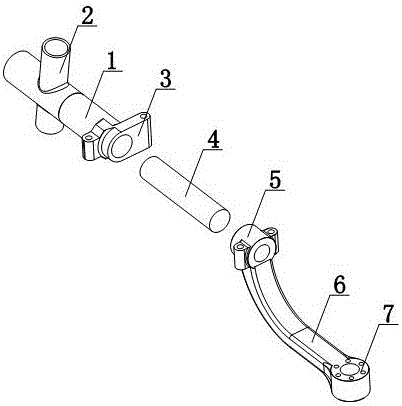

Rod support for metal wire quenching

The invention discloses a rod support for metal wire quenching. The rod support comprises a holding rod; the holding rod is connected with a connecting pipe; the connecting pipe and the holding rod are arranged crosswise; the end part of the holding rod is connected with a connecting block; a connecting rod is inserted into the connecting block; the end part of the connecting rod is provided with a butt joint pipe; the end part of the butt joint pipe is provided with a quenching bar; and the end part of the quenching bar is provided with a quenching casing. According to the rod support disclosed by the invention, a metal wire to be quenched can be installed at the position of the quenching casing, and a user enables the metal wire to approach to a quenching machine by holding the rod support, therefore quenching treatment can be conveniently performed on the metal wire.

Owner:TAIZHOU HONGXIANG POWER MACHINERY

Ink scraper clamping and quenching device for quenching furnace

InactiveCN108085468AFirmly connectedEasy to quenchFurnace typesProcess efficiency improvementEngineeringQuenching

The invention discloses an ink scraper clamping and quenching device for a quenching furnace. The ink scraper clamping and quenching device comprises a substrate and a base plate, wherein a pluralityof clamping pieces are arranged on the base plate; a clamping groove is formed between every two adjacent clamping pieces; clamping plates are arranged on the top surface of the base plate; a clampingseat is arranged at the back of each clamping plate and is arranged on the top surface of the base plate; the plurality of clamping pieces are arranged between the clamping plates; a connecting casing is arranged at the front part of the base plate; side plates are arranged at one side of the connecting casing; a butting pipe is arranged between front parts of the side plates; a hook groove is formed in the outer circumferential surface of the middle part of the butting pipe; an adjusting arm is arranged on the substrate; one end of the adjusting arm is connected with the substrate; a connecting spring is connected to the other end of the adjusting arm; one end of the connecting spring is connected with the other end of the adjusting arm; the other end of the connecting spring sleeves thehook groove. According to the ink scraper clamping and quenching device disclosed by the invention, an ink scraper is clamped between the clamping pieces; the clamping seats can be used for clampingcertain sides of the clamping pieces, which is convenient for the quenching furnace to carry out quenching treatment on the ink scraper.

Owner:SUZHOU ZHONGXINYUAN MICROELECTRONICS CO LTD

Medical suture needle inserting frame

InactiveCN105441662AEasy dockingEasy to quenchFurnace typesHeat treatment furnacesSuturing needleButt joint

The invention discloses a medical suture needle inserting frame which comprises an inserting plate. The inserting plate is provided with an inserting ring, and the inserting ring and the inserting plate are both provided with a plurality of inserting holes. A connecting strip is arranged on one side of the inserting ring and connected with the inserting plate, a butt-joint strip is arranged on the other side of the inserting ring, and a lock pin is arranged at one end of the butt-joint strip. According to the medical suture needle inserting frame, medical suture needles can be inserted into the inserting plate and the inserting ring, the inserting frame can get close to a fire source, and therefore the medical suture needles can be in butt joint with the fire source conveniently, and quenching treatment is facilitated.

Owner:王丽

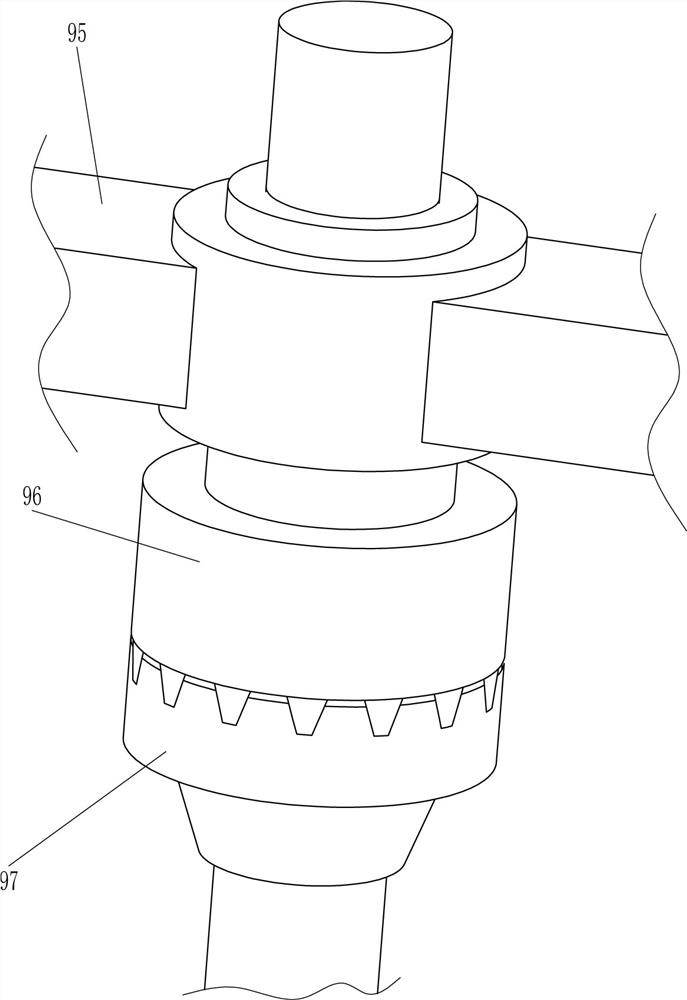

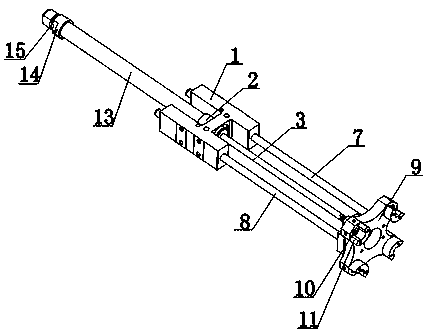

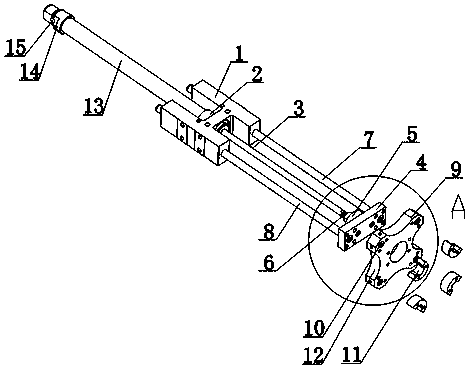

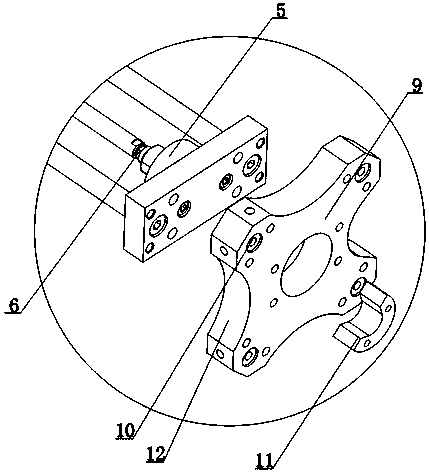

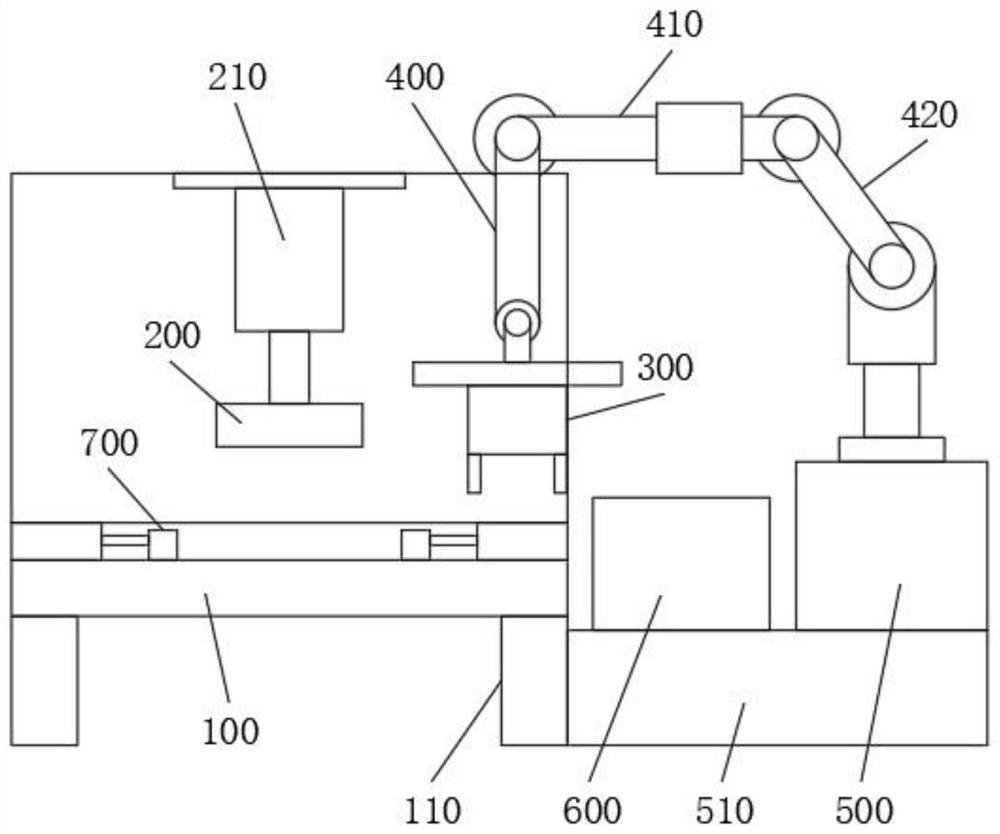

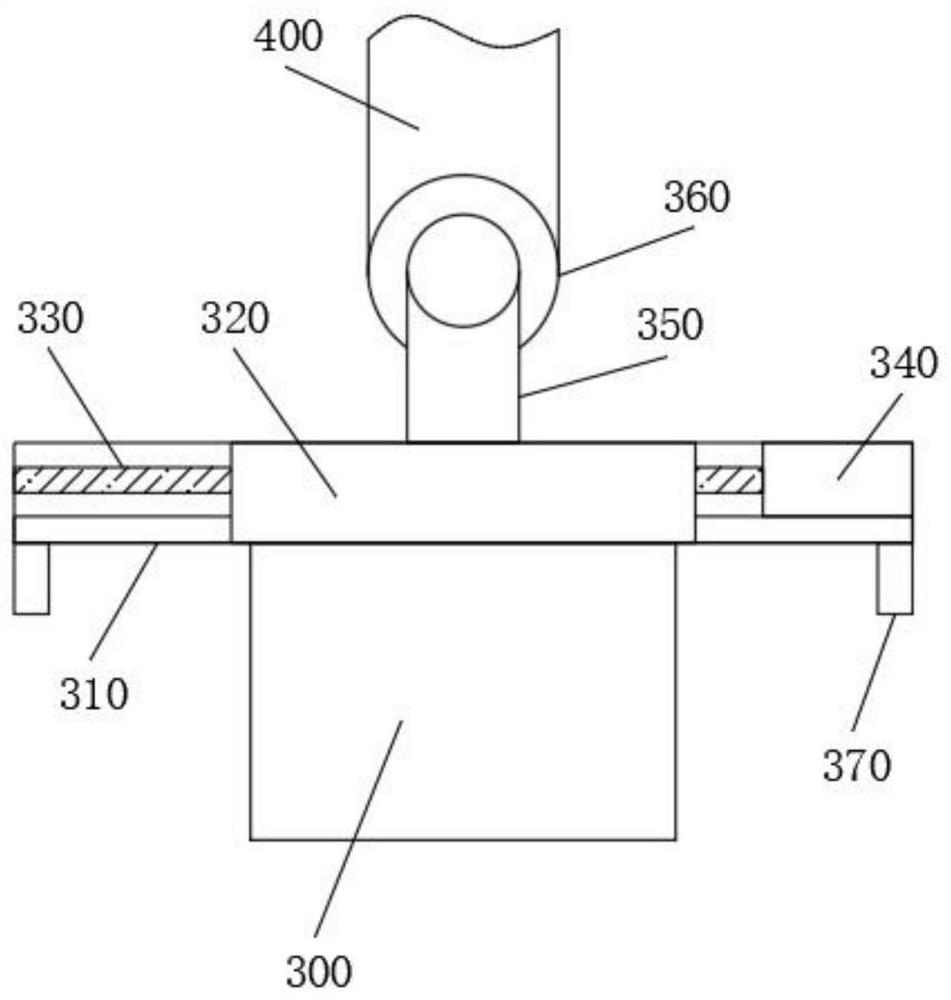

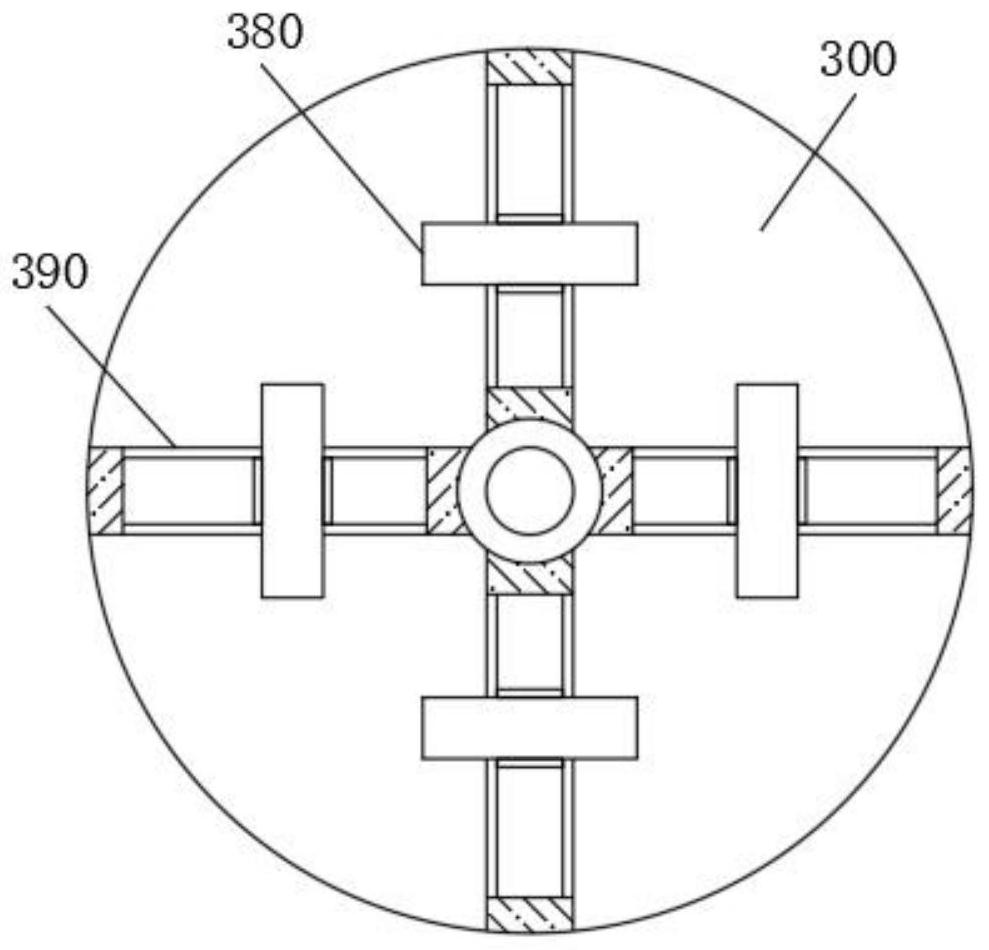

A special laser quenching rack for coal picks

InactiveCN109266823BHarm reductionNovel structureFurnace typesHeat treatment furnacesAutomatic controlLaser quenching

The invention relates to auxiliary equipment for quenching process, in particular to a laser quenching rack special for cutting picks of a coal cutter. A laser quenching process area is isolated froma receiving area and a conveying area so that harm from pollutants of light pollution and exhaust gas pollution to the human body during the laser quenching is avoided effectively and labor intensityis reduced greatly; the whole laser quenching process has high level of automation, work efficiency of the laser quenching is increased; under cooperation of a conveying belt, a first L-shaped rotaryarm and a second L-shaped rotary arm realizes transferring of the cutting picks, and thus the process can be completed by controlling mechanical arms through an automatic control system during the laser quenching; after finishing the process, the cutting picks are recovered into a collecting barrel automatically through the conveying belt, workers are protected against being scaled by afterheat ofthe processing of the cutting picks, and safety and health of the workers are protected effectively. The laser quenching rack is of reliable structure and capable of improving work efficiency of thelaser quenching process of the cutting picks.

Owner:ZHONGYUAN ENGINEERING COLLEGE

Heat treatment quenching device

The invention discloses a quenching device for heat treatment, which comprises a condensation box, a water accumulation chamber is arranged inside the condensation box, a cooling tank is arranged on the top of the condensation box, and a water discharge tank is fixedly connected to the outer side wall of the condensation box. The outlet end of the water tank is provided with a first water pipe, and the end of the first water pipe away from the water tank runs through the condensation tank and extends to the water accumulation chamber. The bottom of the water accumulation chamber is fixedly connected with a support rod, and the support rod rotates A control rod is connected, and one end of the control rod is fixedly connected with a floating ball. In the present invention, through the cooperation of the water inlet mechanism and the second water pipe, the cooling water in the cooling tank is continuously circulated, so as to avoid the waste of water resources. In addition, through the cooperation of the floating ball, the control rod, the sealing plug and the first water pipe, the accumulation of water is ensured. The water chamber always contains condensed water, thereby ensuring the continuous battery life of the condensed water in the cooling tank, so that people can continue to perform quenching treatment.

Owner:马鞍山祥源机械厂

Method for degrading nitrobenzene waste water by polyphase electrocatalytic oxidation-Fenton coupling process and reactor thereof

InactiveCN101838074BPromote generationRapid and effective degradationMultistage water/sewage treatmentWater/sewage treatment by oxidationHigh energyHomogeneous catalysis

The invention belongs to the technical field of treatment of high concentration organic waste water, and particularly relates to a method for degrading nitrobenzene waste water by a polyphase electrocatalytic oxidation process. The invention solves the problems of high cost and long time consumption in the traditional nitrobenzene waste water methods, low efficiency and high energy consumption inthe electrolytic process, high oxidant consumption, high cost and the like in the Fenton process in the prior art for treating high concentration nitrobenzene water waste. The invention mainly adoptsthe catalytic oxidation action of transition metal catalysts in the electric field, and combines the Fenton process, thereby effectively degrading the high concentration nitrobenzene waste water. Themethod comprises the following steps that: (1) heterocatalytic reagents (solid catalysts) and particle electrodes, mainly including active carbon, and transition metal oxides and salts, are used for avoiding economic loss and secondary pollution to the environment, which are caused by catalyst loss in heterocatalytic oxidation; (2) under the condition of low pH value of the waste water in cooperation with Fe2+ with strong reducibility, a coupling reactor composed of an electrolysis field and oxidation reaction is used for generating chain reaction for generating an OH hydroxyl free radical, and the OH hydroxyl free radical can carrying out nonselective oxidization on organic substances, thereby finally oxidizing organic pollutants into carbon dioxide and water; (3) by using electric energy as an excitation energy and using cheap air as raw material, nitrobenzene substances in waste water are efficiently degraded under the coupling action of the polyphase electrocatalytic oxidation process and the Fenton process; (4) and the reactor is composed of a direct current regulated power supply, a feed electrode and an electrolytic bath.

Owner:广东华凯明信科技有限公司

Quenching rack for precision metal gaskets

The invention discloses a quenching rack for precision metal gaskets. The quenching rack comprises a rack body, wherein a mounting groove is formed in the rack body, a connecting rod is arranged on the rack body in a plugging manner, a sleeving cylinder is arranged in the position of the mounting groove, a plurality of clamping grooves are formed in the outer surface of the sleeving cylinder, one end of the connecting rod is a free end, and the other end of the connecting rod penetrates through the axial direction of the sleeving cylinder and is connected with the rack body. Precision metal gaskets to be processed by quenching can be arranged in the positions of the clamping grooves in the sleeving cylinder in a sleeving manner, and then, the rack body is mounted on quenching equipment, so that quenching processing can be conveniently carried out on the precision metal gaskets.

Owner:安徽普力森特钢股份有限公司

Continuous quenching device for track with turnover function

ActiveCN109338055AWith flip functionConvenient and continuous flip operationFurnace typesHeat treatment furnacesEngineeringQuenching

The invention discloses a continuous quenching device for a track with a turnover function. The continuous quenching device comprises a base frame, a conveying roller, a flame nozzle, a spray pipe, aservo motor and a blocking plate, wherein the conveying roller and a mounting plate are arranged on the inner wall of the base frame, the flame nozzle and the spray pipe are arranged on the lower endface of the mounting plate, and the servo motor is arranged on the outer wall of the base frame. An inner channel is formed in an adjusting cylinder, and a reset spring is fixed in the adjusting cylinder. An extending plate is fixedly arranged on a control plate. The blocking plate is fixed to a bottom plate, and the bottom plate is fixed to the bottom surface of the base frame. A transferring plate is fixedly arranged on the inner wall of the base frame. By adopting a novel structural design, the continuous quenching device for the track with the turnover function can conveniently and continuously carry out turnover operation for a track shoe of which the single face is quenched. The structure is stable and reliable, manual operation is not needed, the safety of production is improved, and the efficiency of production is also greatly improved.

Owner:HUNAN SANTER MACHINERY MFG

Machine shell-mounted spray gun

InactiveCN105316457AEasy to installEasy and secure installationQuenching devicesPulp and paper industryQuenching

The invention discloses a machine shell-mounted spray gun, which comprises a shell, wherein a cramp is arranged at one side of the shell; a mounting shell is arranged on the other side of the shell; a connecting pipe is arranged on the mounting shell; the connecting pipe is provided with a spray pipe in a sleeving way; the spray pipe is oblique; and the spraying pipe is connected with the connecting pipe by threads. According to the machine shell-mounted spray gun, the spray gun can be conveniently and firmly mounted by the shell; the spray pipe can be conveniently in butt joint with the spray gun, so that flame is convenient to jet, the quenching of an object is facilitated, and the quenching efficiency is greatly improved.

Owner:胡和萍

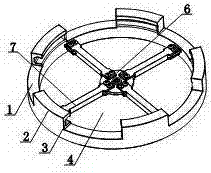

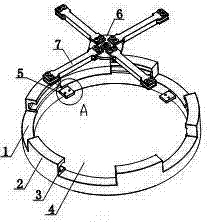

Auxiliary quenching device of compound gasket metal sealing ring

InactiveCN106868265AConvenient rotation operationEasy to quenchFurnace typesHeat treatment furnacesEngineeringQuenching

The invention discloses an auxiliary quenching device of a compound gasket metal sealing ring. The auxiliary quenching device comprises a sleeve seat; the sleeve seat is annular; a plurality of buckle blocks are arranged on the sleeve seat; buckle grooves are formed in the inward surfaces of the buckle blocks; a mounting groove is formed in the axial position of the sleeve seat; a plurality of limiting blocks are arranged on the inner side wall of the sleeve seat, and are arranged in the position of the mounting groove; a quenching rack is arranged on the sleeve seat, and comprises a connecting ring; the cross section of the connecting ring is circular; the connecting ring is connected with a plurality of connecting strips; a first clamping groove is formed in one end of each connecting strip; the connecting ring is connected with the first clamping grooves in clamping manner; second clamping grooves are formed in the other ends of the connecting strips; the limiting blocks are connected with the second clamping grooves in a clamping manner; the connecting ring is connected with one end of each connecting strip through first fixed bolts; and the limiting blocks are connected with the other ends of the connecting strips through second fixed bolts. With the adoption of the auxiliary quenching device, rotation operation and quenching treatment on the compound gasket metal sealing ring on a sleeve seat can be carried out conveniently.

Owner:SHANGHAI ZHAOYI ELECTRONICS TECH CO LTD

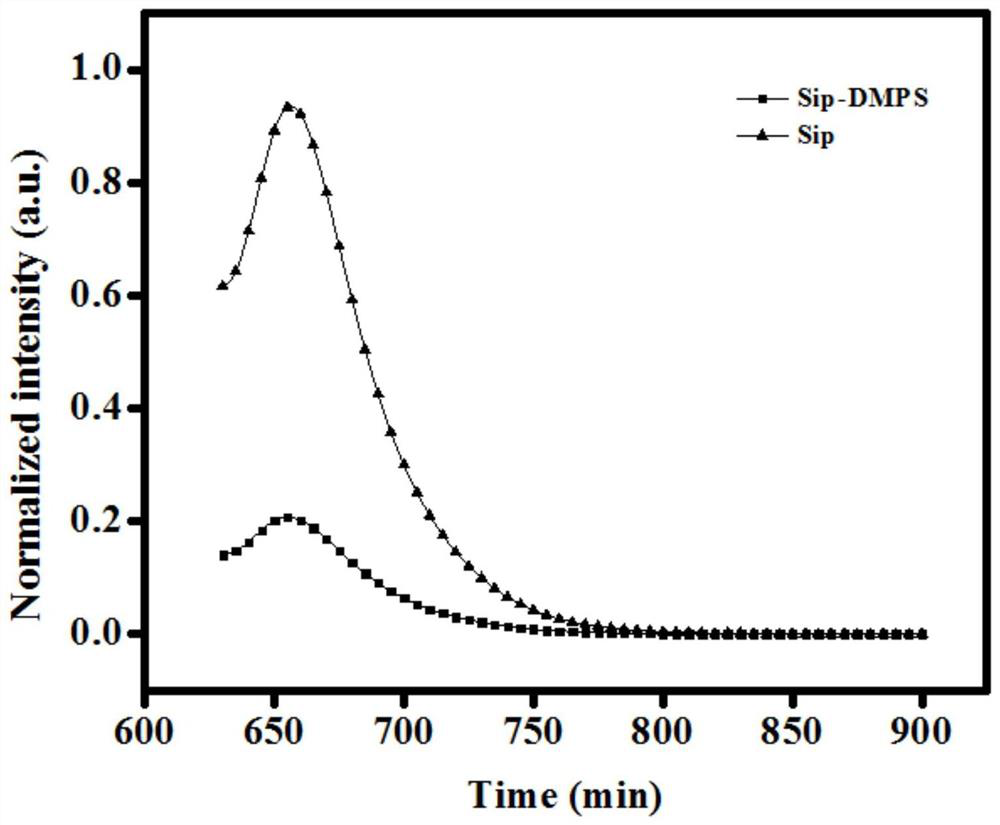

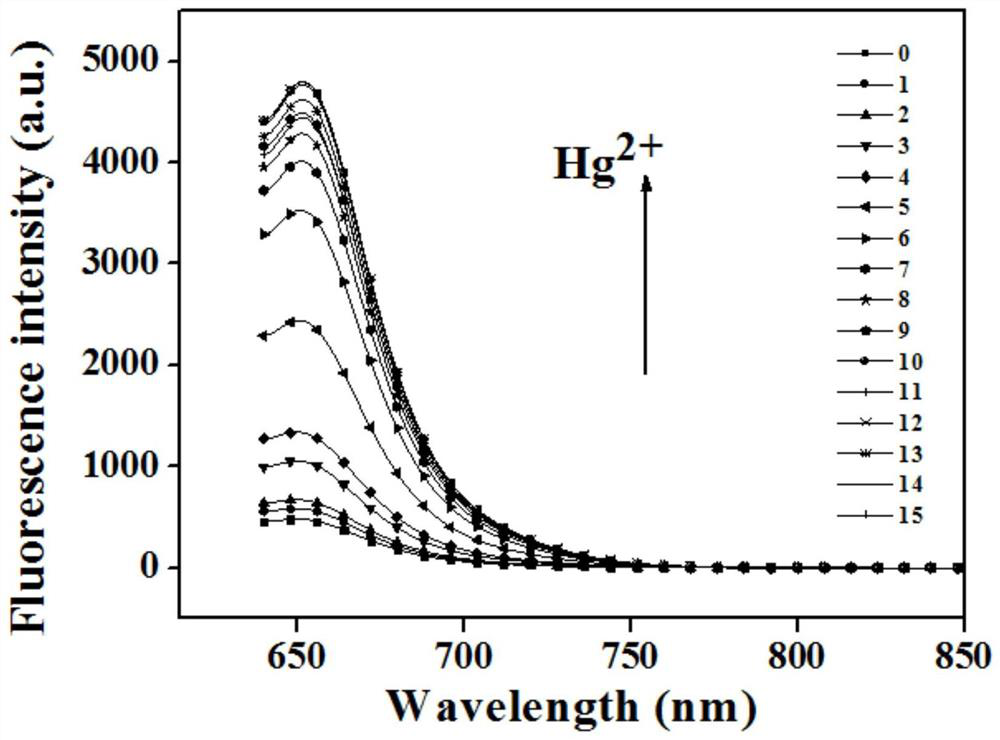

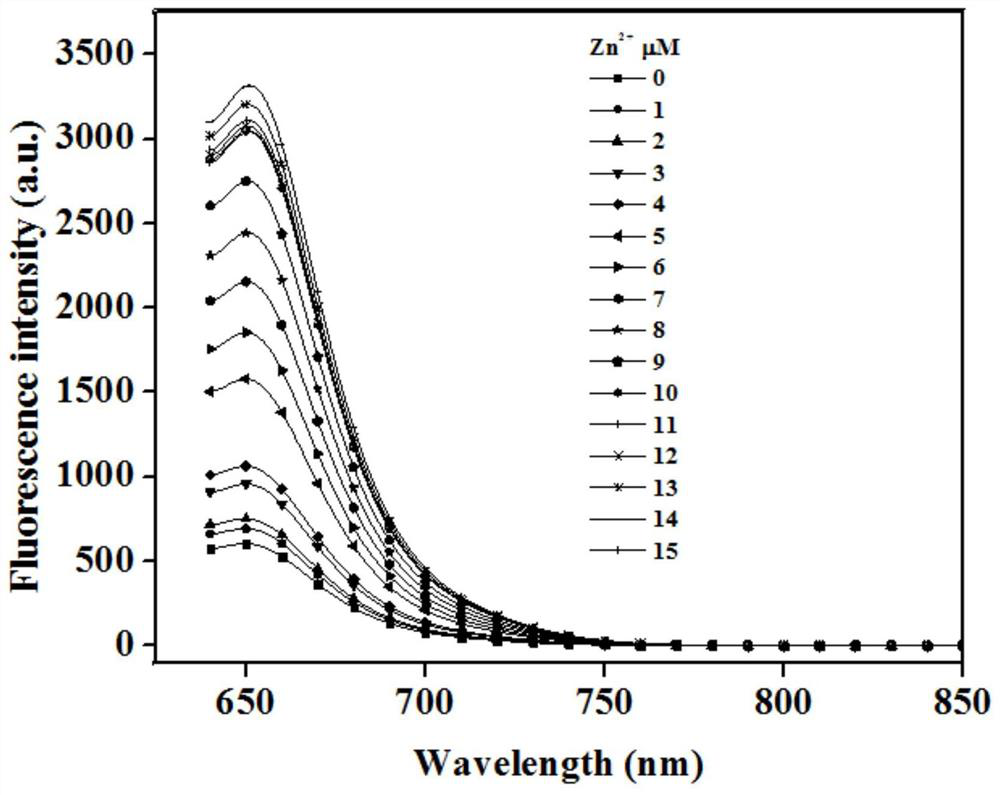

Heavy metal ion indicator based on sip-me/dmps reversible reaction and its application

ActiveCN112326644BLong emission wavelengthGood light stabilityMaterial analysis by observing effect on chemical indicatorFluorescence/phosphorescenceButanedioic acidMercuric ion

The invention provides a heavy metal ion indicator based on Sip-Me / DMPS reversible reaction and its application. Silpiro red and sodium 2,3-dimercaptopropanesulfonate are mixed and reacted at room temperature according to the volume ratio of 1:2, and the reaction Afterwards, the heavy metal ions were detected by using silpirole red as the fluorophore and the dithiol group as the recognition site. At the same time, the water-absorbing bomb absorbed with silpiro red and 2,3-dimercaptopropanesulfonate solution was used as an indicator, and the reaction between silpiro red and 2,3-dimercaptopropanesulfonate made the fluorescence quenched, and then mixed with Heavy metal ions react to form complexes to remove dimercaptosuccinic acid, so that the fluorescence of the system is restored, and the presence of mercury ions, zinc ions, nickel ions, cadmium ions, copper ions and cobalt ions, six heavy metal ions can be detected.

Owner:ZHENGZHOU UNIV

A intelligent fixture forging device

ActiveCN112893748BHigh strengthIncrease elasticityForging/hammering/pressing machinesForging press detailsElectric machineMachine building

The invention discloses an intelligent clamping and forging equipment, comprising a work table, a forging plate, a clamping device, a first mechanical arm, a rotary drive motor, a quenching box and a positioning plate. The bottom outer end of the work table is fixedly welded and distributed with Support legs, all of which are cylindrical steel pipe structures, the bottom of the support legs are bonded with EVA pads, the positioning plates are arranged at the top ends of the work table, and the outer ends of the positioning plates are fixed with A second screw rod, the outer end of the second screw rod is connected with a second electric push rod device, a forging plate is provided above the work table, and the top of the forging plate is connected with a hydraulic device through a hydraulic rod, the The top of the hydraulic device is fixedly welded with a top plate, and the side end of the forged plate is provided with a clamping device. The intelligent clamping forging equipment relates to the technical field of mechanical manufacturing, forging workpieces with high strength, sliding and clamping the workpieces, high automation performance, lateral sliding adjustment of positions, and quenching processing after forging.

Owner:LAIWU FORGING

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com