Quenching shape control method for flexible die of aluminum alloy curved surface part for spaceflight

A flexible mold and aluminum alloy technology, applied in forming tools, manufacturing tools, metal processing equipment, etc., can solve the problems of difficult flow filling, heat treatment distortion, low pass rate, etc., to achieve improved success rate, easy operation, and simple structure Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

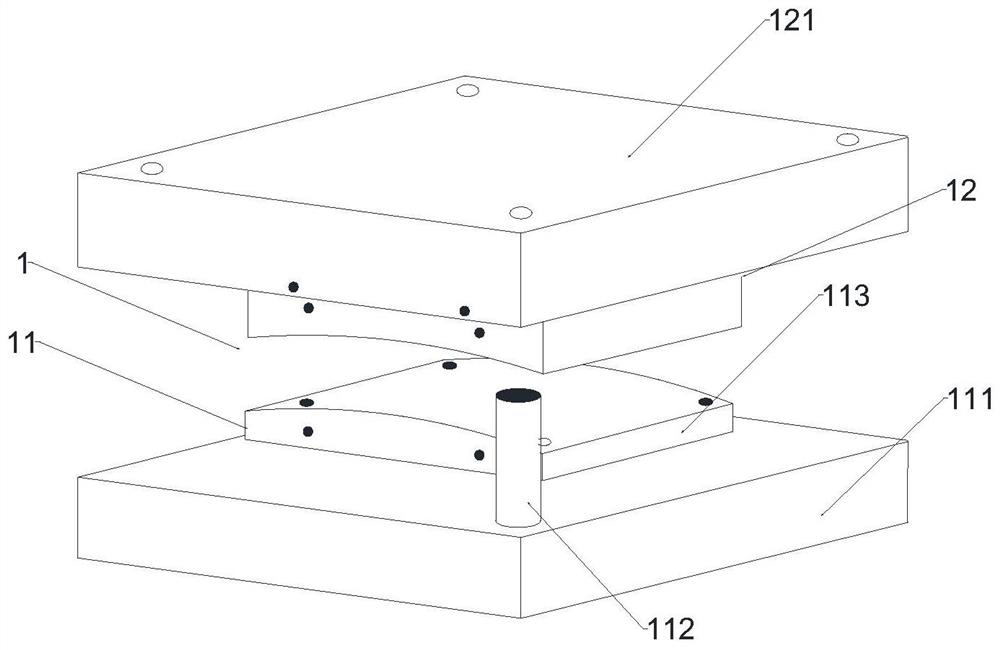

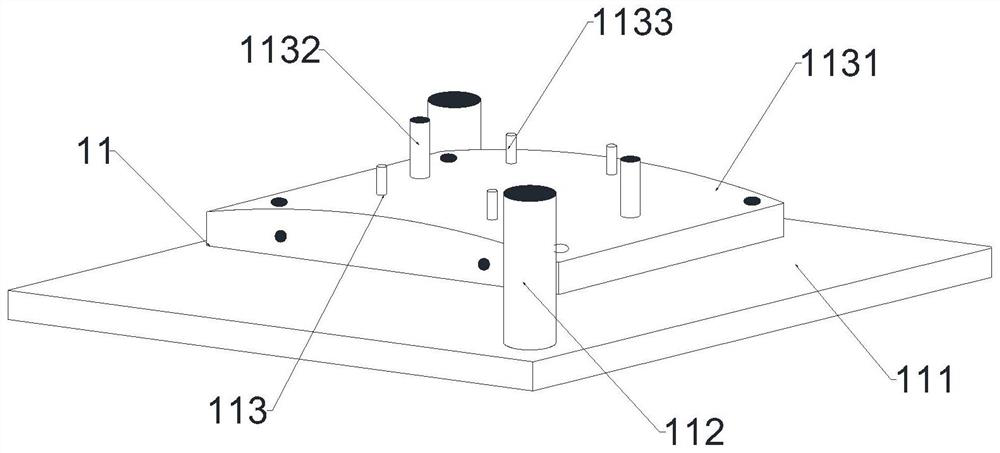

[0047] According to the structural characteristics of large depth and large curvature structural surface parts of aluminum alloys used in aerospace, special-purpose flexible quenching molds are designed, such as figure 1 shown.

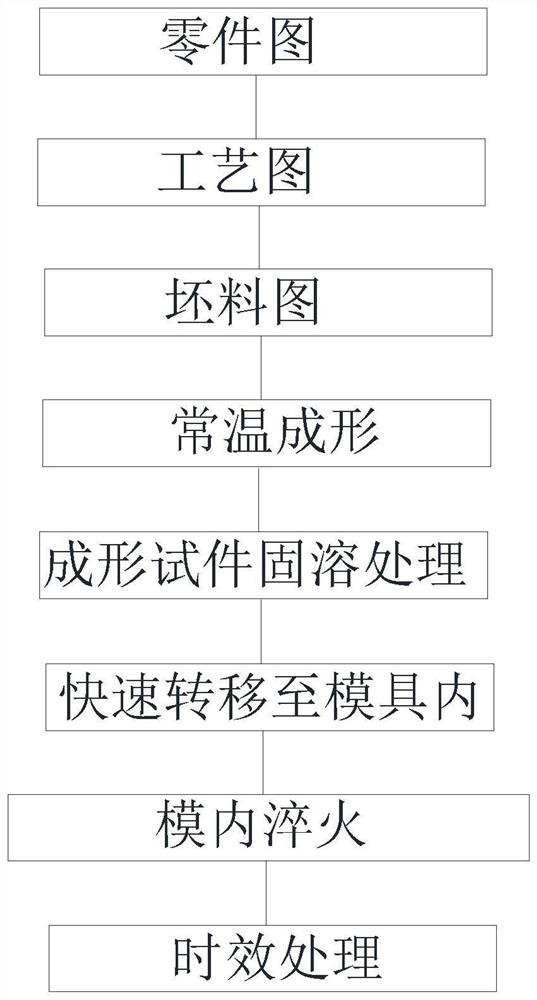

[0048] According to the deformation characteristics of thermal deformation-quenching composite forming, the direct thermal deformation-quenching composite forming process of flat plate is formulated, that is, after the flat slab is solid-solution heated, it is directly transferred to the cold mold for forming and quenched in the mold, and then improved by aging. strength. Forming process such as image 3 shown.

[0049] 1) Obtain the slab blanking diagram according to the product structure characteristics and the size of the technical blank;

[0050] 2) Pre-drawn parts at room temperature;

[0051] 3) According to the heat treatment specifications of the materials used in the parts and the heating speed of the furnace, the solid solution heating t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com