A special laser quenching rack for coal picks

A technology of laser quenching and coal picking, which is applied to quenching devices, furnaces, furnace types, etc., can solve the problems of difficult laser protection, high labor intensity of workers, and high process requirements, so as to reduce the harm of laser and waste heat to workers and reduce Manual workload, convenient quenching effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

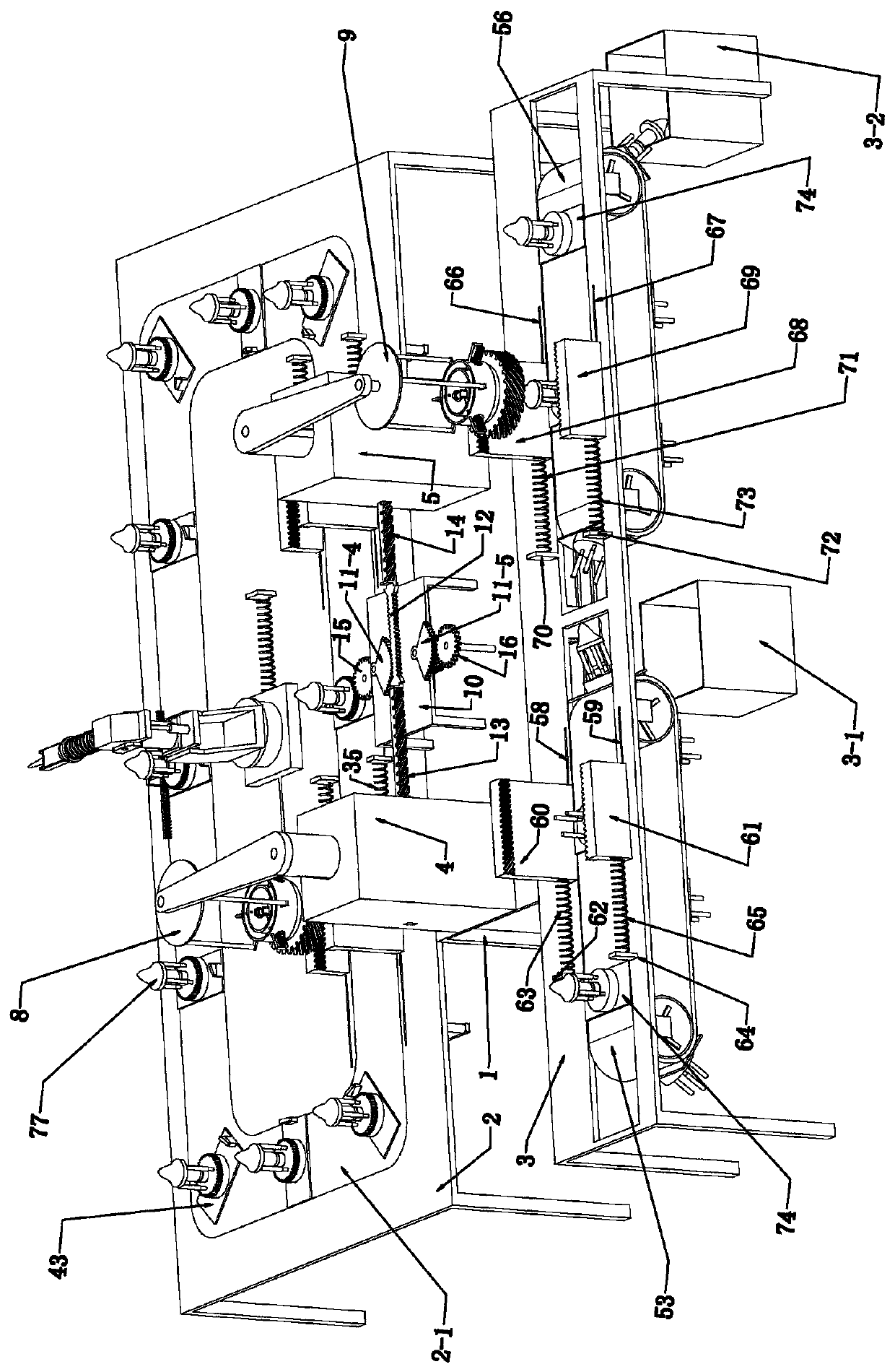

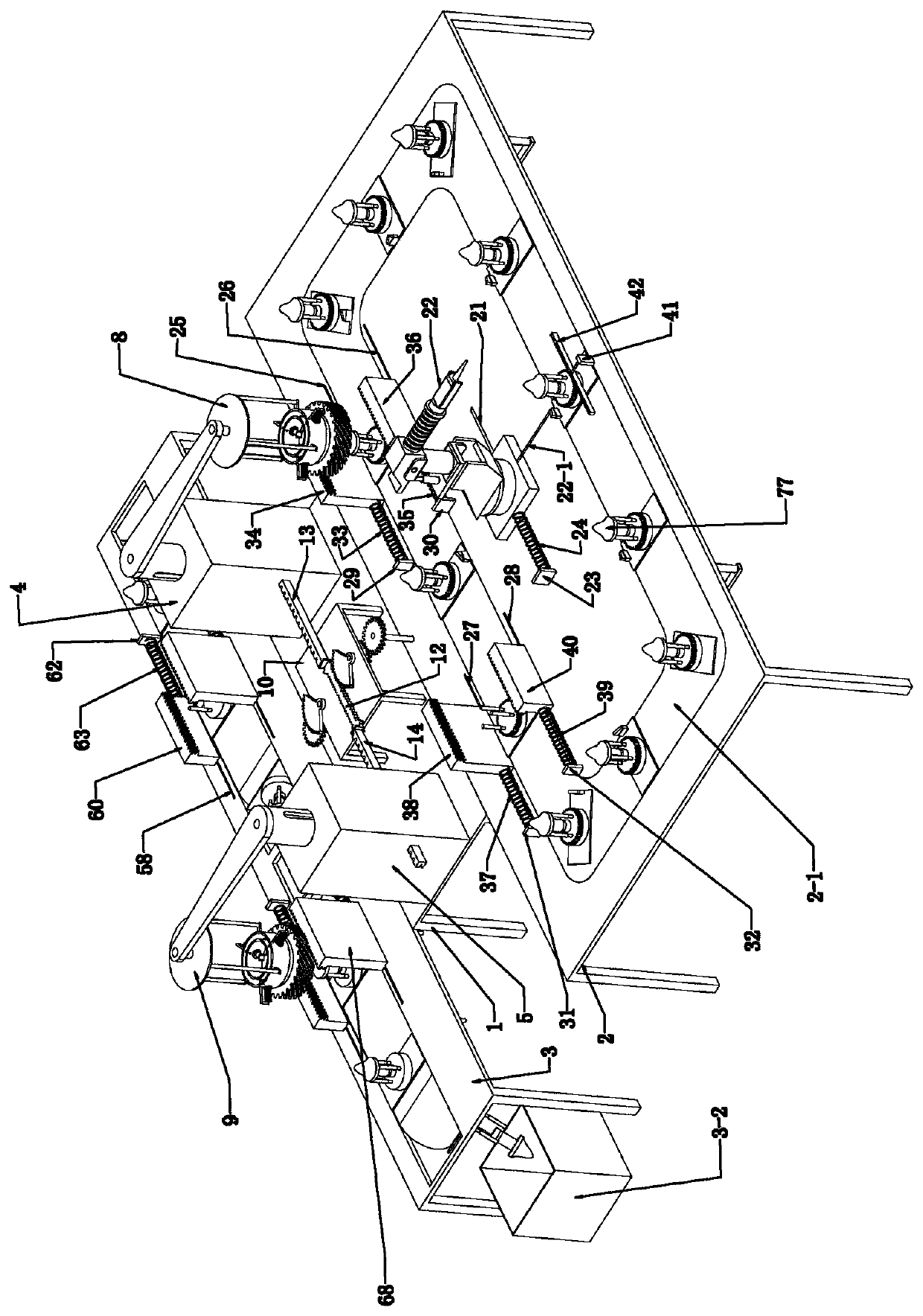

[0034] Example 1. Please attach figure 1 -Attached Figure 15 , A special laser quenching frame for coal picks, comprising a drive frame 1, a work frame 2 is provided on one side of the drive frame 1, a feeding frame 3 is provided on the other side of the drive frame 1, and the upper end surface of the drive frame 1 A first box body 4 and a second box body 5 are fixedly installed at both ends of the first box body 4, and a first cylindrical inner cavity 4-1 is opened in the first box body 4. Coaxially slidingly cooperates with a first L-shaped rotating arm 6 which penetrates upwards from the upper end surface of the first box body 4, and the lower end of the first L-shaped rotating arm 6 is coaxially connected with a first worm 6-2, which satisfies the requirements of the first An L-shaped rotating arm 6 slides and rotates in the first cylindrical inner cavity 4-1 driven by the first worm 6-2, and a second cylindrical inner cavity 5 is opened in the second box body 5 -1, the s...

Embodiment 2

[0039] Embodiment 2 On the basis of Embodiment 1, the retracting drive device on the upper end surface of the work frame 2 includes a second rail 25, a third rail 26, a fourth rail 27, and a fifth rail extending along the extending direction of the first rail 21. Rail 28, the second rail 25 is provided with a second fixing plate 29 on one side in the extending direction, the third rail 26 is provided with a third fixing plate 30 on one side in the extending direction, and the fourth rail 27 is provided on one side in the extending direction There is a fourth fixing plate 31, a fifth fixing plate 32 is provided on one side of the fifth rail 28, the second rail 25 and the third rail 26 are close to the first box 4 and are located on the first conveyor belt 2-1 Distributed on both sides, the fourth rail 27 and the fifth rail 28 are close to the second box body 5 and distributed on both sides of the first conveyor belt 2-1, the second rail 25 is slidably mounted and connected to the...

Embodiment 3

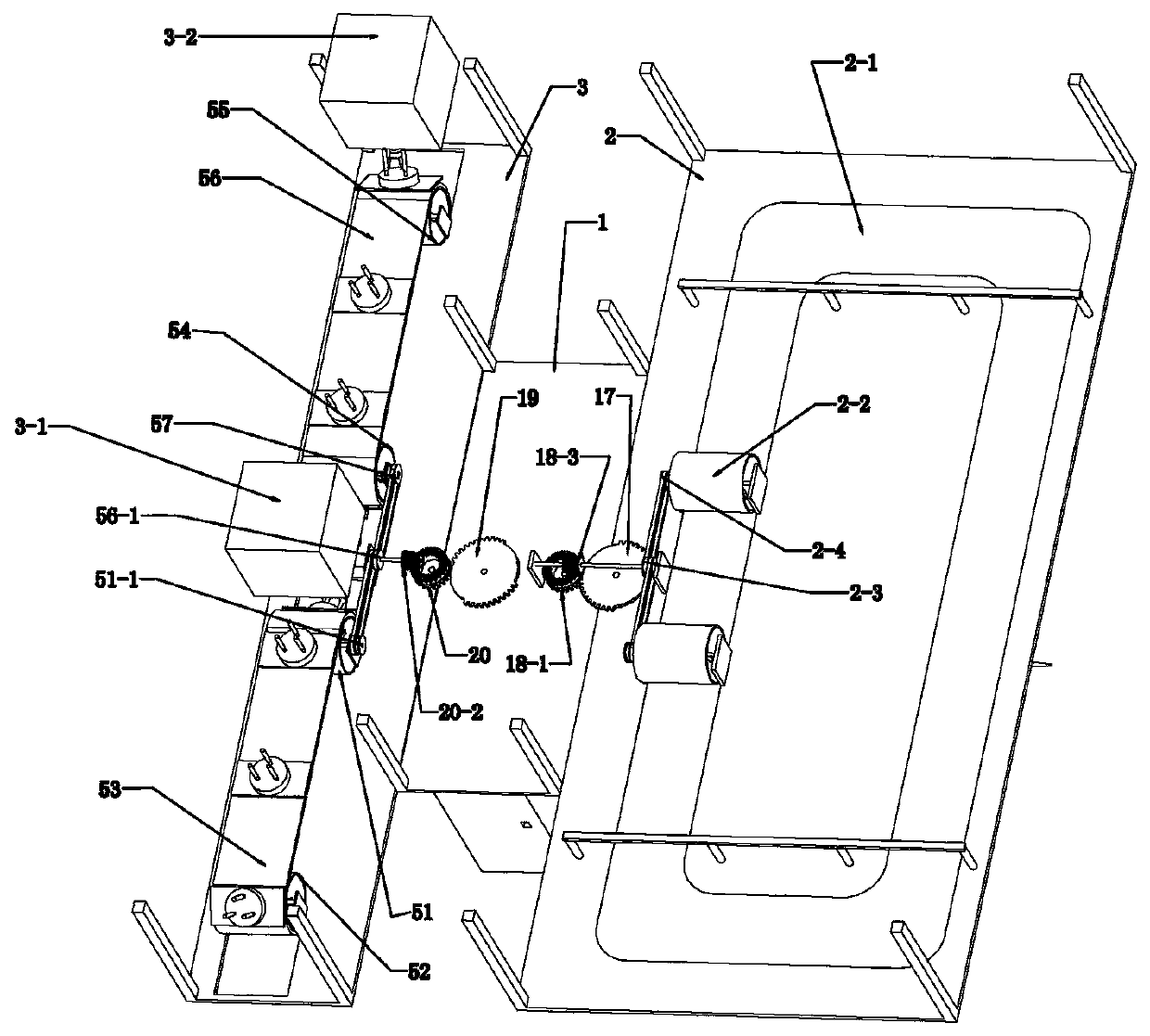

[0041] Embodiment 3 On the basis of Embodiment 1, the lower end of the work frame 2 is rotatably installed with a plurality of first transmission cylinders 2-2 for driving the first conveyor belt 2-1, and the lower end of the work frame 2 is provided with a driving second The first drive pulley 2-3 of a transmission cylinder 2-2, the first drive pulley 2-3 is driven by the first steering worm 18-3, and the first transmission cylinder 2-2 is fixed and coaxially mounted The first driven pulley 2-4, the first driving pulley 2-3 drives the first driven pulley 2-4 via a belt, and in the implementation process, the first steering worm 18-3 passes through the first driving pulley The cooperation of 2-3 and the first driven pulley 2-4 drives the first transmission drum 2-2 to rotate and finally drives the first conveyor belt 2-1;

[0042] The feeding rack 3 is rotatably installed with a second transmission cylinder 51 and a third transmission cylinder 52 on the lower end surface close to...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com