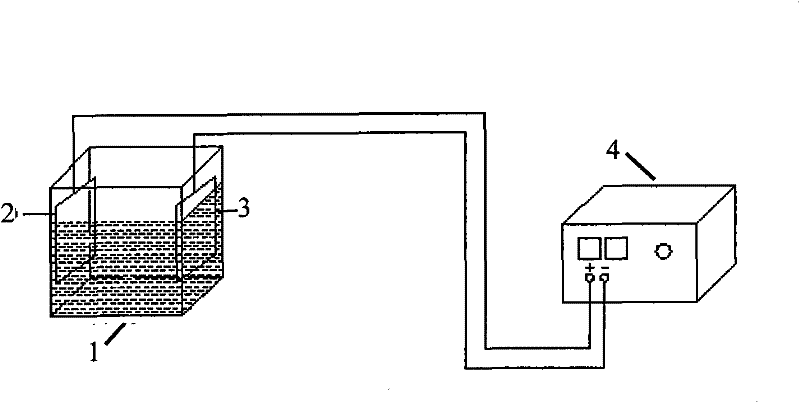

Method for degrading nitrobenzene waste water by polyphase electrocatalytic oxidation-Fenton coupling process and reactor thereof

A nitrobenzene wastewater, catalytic oxidation technology, applied in chemical instruments and methods, oxidized water/sewage treatment, water/sewage multi-stage treatment, etc., can solve the problems of unacceptable, slow nitrobenzene degradation and high cost , to achieve the effect of ensuring compliance with emission standards

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

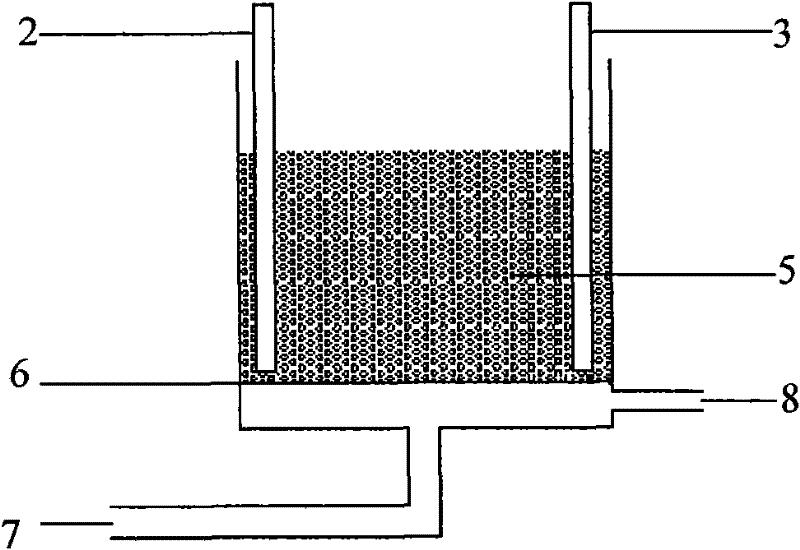

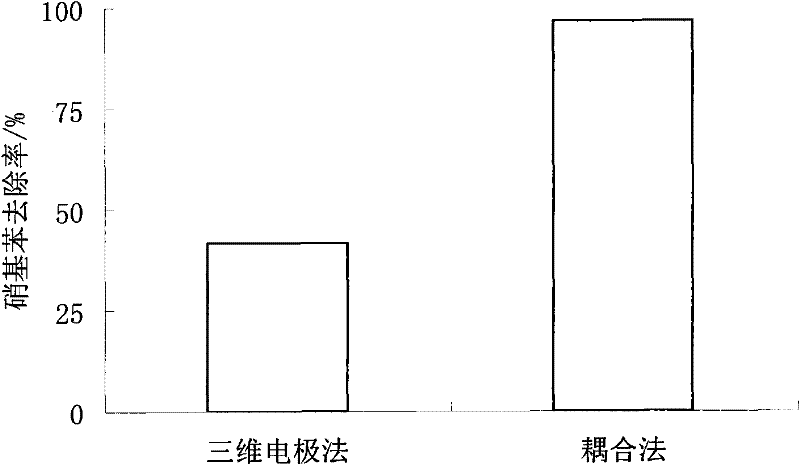

Method used

Image

Examples

Embodiment 1

[0038] In terms of weight percentage, based on activated carbon and iron filings accounting for 98% of the electrode particles, 0.01% platinum oxide, 0.02% palladium oxide, 0.1% nickel oxide, 0.2% cobalt oxide, 0.3% Zinc oxide, 0.37% copper oxide and 1% manganese dioxide are used as solid catalysts, and activated carbon or / and iron filings and solid catalysts are fully mixed to form particle electrodes with a particle size of 4-6mm as electrodes; cathode electrode plates Graphite is used, the anode electrode plate is made of RuO 2 -IrO2 -TiO 2 / Ti, as the feeding electrode, the initial pH of nitrobenzene wastewater is 3, the distance between the plates is 6cm, the cell voltage is 30V, Fe 2+ The dosage is 1.0g / L (add in 6 times), the aeration volume is 0.8m 3 Under the condition of COD 18000mg / L and nitrobenzene content 1300mg / L, the nitrobenzene wastewater was treated for 90 minutes, and the removal rates of COD and nitrobenzene were 93.1% and 96.5%, respectively.

[0039] ...

Embodiment 2

[0041] Based on activated carbon and iron filings accounting for 94% of the electrode particles, 0.01% platinum oxide, 0.02% palladium oxide, 0.2% nickel oxide, 0.3% cobalt oxide, 0.47% Zinc oxide, 1% copper oxide, and 4% manganese dioxide are used as solid catalysts, and active carbon or / and iron filings and solid catalysts are fully mixed to form particle electrodes with a particle size of 4-6mm as working electrodes; cathode electrodes The plate is made of graphite, and the anode electrode plate is made of RuO 2 -IrO 2 -TiO 2 / Ti, as the feeding electrode, the initial pH of nitrobenzene wastewater is 2, the distance between the plates is 4cm, the cell voltage is 20V, Fe 2+ The dosage is 0.8g / L (add in 4 times), the aeration volume is 0.6m 3 Under the condition of COD 3440mg / L, the rosin production wastewater was treated for 90 minutes, and the removal rate of COD was 82.5%.

Embodiment 3

[0043] In terms of weight percentage, iron filings accounting for 96% of the electrode particles are used as the substrate, and 0.01% of platinum oxide, 0.02% of palladium oxide, 0.2% of nickel oxide, 0.3% of cobalt oxide, and 0.47% of zinc Oxide, 1% copper oxide and 2% manganese dioxide are used as solid catalysts, and activated carbon or / and iron filings and solid catalysts are fully mixed into particle electrodes with a particle size of 4-6mm as the working electrode; activated carbon or / Fully mix with iron filings and solid catalyst to form a particle electrode with a particle size of 4-6mm as the working electrode; the cathode electrode plate is made of graphite, and the anode electrode plate is made of RuO 2 -IrO 2 -TiO 2 / Ti, as the feeding electrode, as the feeding electrode, at the initial pH of 4, the distance between the plates is 8cm, the cell voltage is 40V, Fe 2+ The dosage is 1.2g / L (add in 5 times), the aeration volume is 1.0m 3 Under the condition of COD 2...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com