Casting method of high-matrix-hardness GM241 alloy gray iron

A technology of GM241 and matrix hardness, which is applied in the field of automobile mold cast iron, can solve the problems of alloy gray iron cracking and other problems, and achieve the effect of easy quenching

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

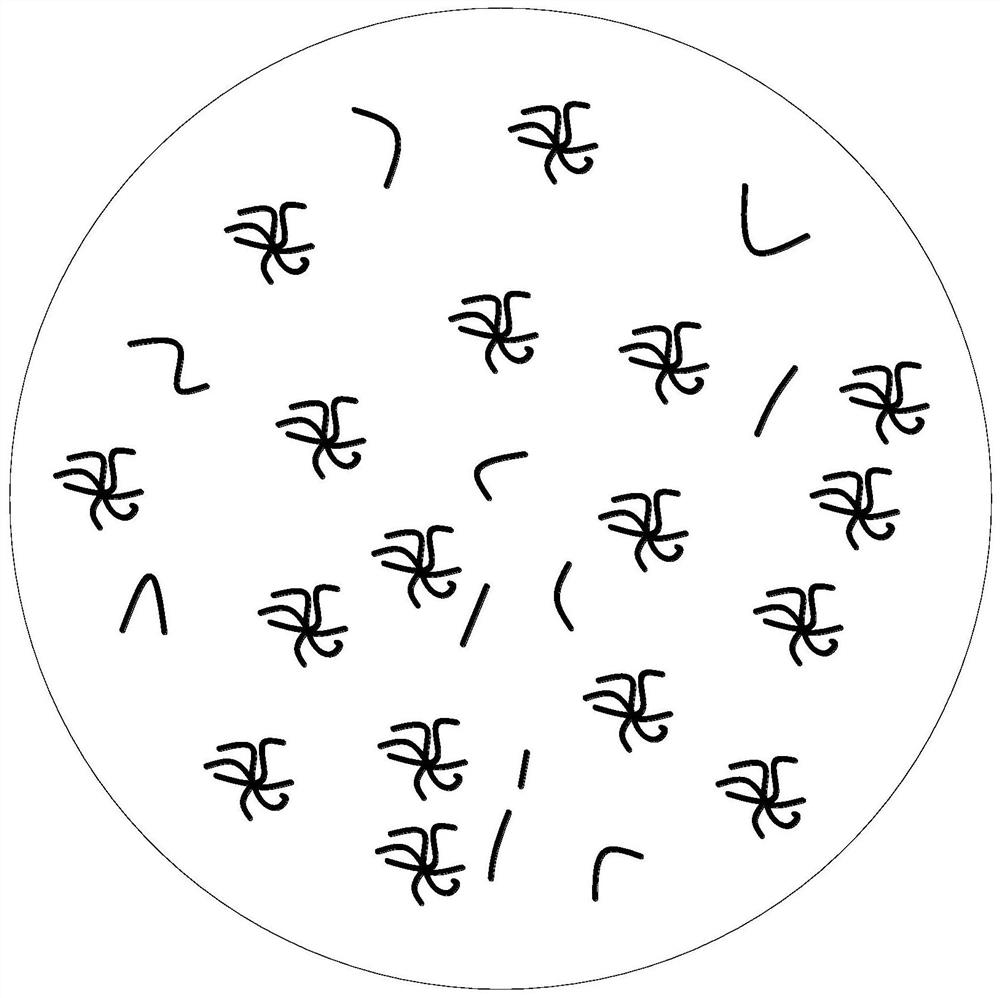

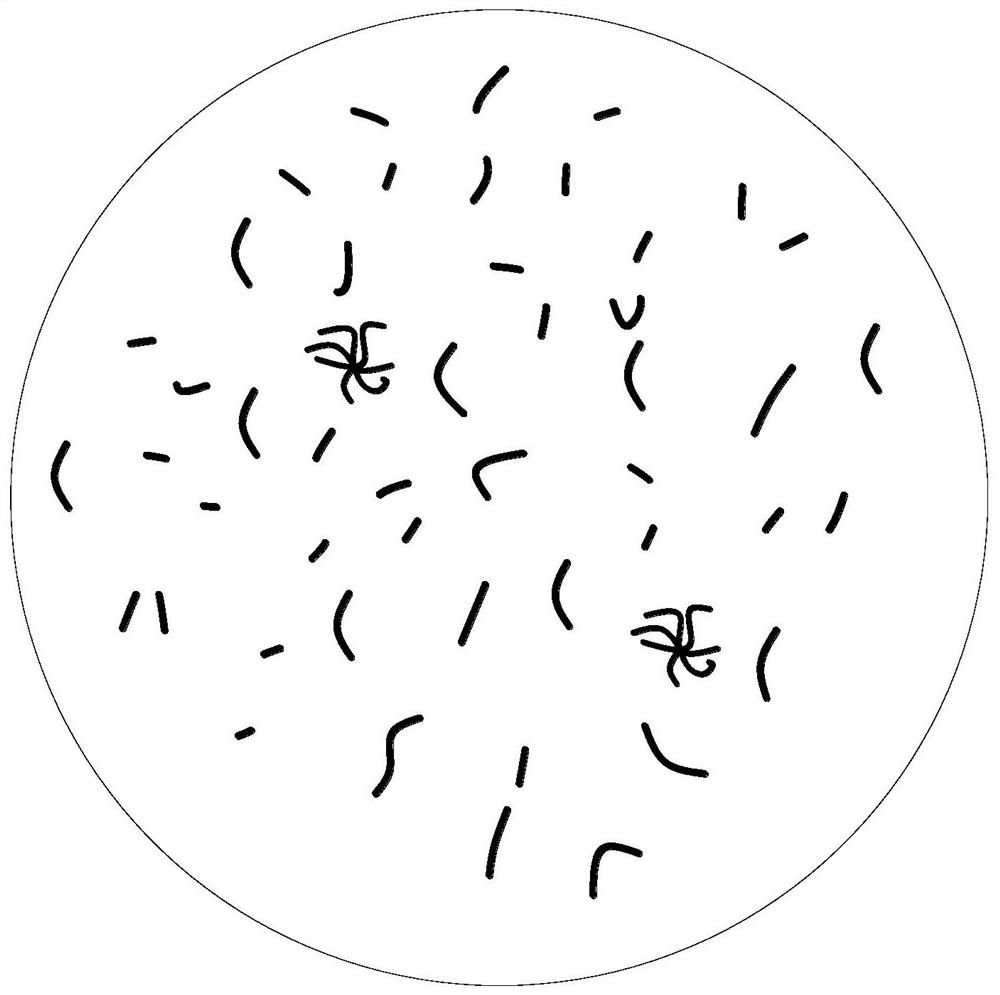

[0037] see Figure 1-3 , a method for casting high matrix hardness GM241 alloy gray iron, comprising the following steps:

[0038] S1: GM241 alloy gray iron is composed of C: 3.0% ~ 3.2%, Si: 1.6% ~ 1.8%, Mn: 0.9% ~ 1.0%, P: ﹤0.06%, S﹤0.1%, Cu: 0.3% ~ 0.5%, Ni: 0.10%~0.15%, Mo: 0.4%~0.5% and Cr: 0.4%~0.5%, the percentage data is the percentage content of each element in the casting, that is: the weight of the element in the molten iron (kg) / The total weight of molten iron (kg) * 100% = percentage content; the graphite length of GM241 alloy gray iron is 50 ~ 70um, A-type graphite ≧ 90%, 90% means in the field of view of the microscope (×100 times), The ratio of the amount of type A graphite to the total number of graphite in the field of view, that is: the number of type A graphite / the total number of graphite in the field of view * 100% ≥ 90%; hardness 220 ~ 241HB, quenching hardness ≧ 52HRC, increase the proportion of type A graphite, refine the length of graphite , impr...

Embodiment 2

[0047] see figure 1 , a method for casting high matrix hardness GM241 alloy gray iron, comprising the following steps:

[0048] S1: GM241 alloy gray iron is composed of C: 3.0%, Si: 1.6%, Mn: 0.9%, P: 0.06%, S: 0.1%, Cu: 0.3%, Ni: 0.10%, Mo: 0.4% and Cr: 0.4 % composition, GM241 alloy gray iron graphite length 20um, A-type graphite 50%, hardness 220~241HB, quenching hardness≧52HRC;

[0049] S2: The molten iron is dissolved in an intermediate frequency induction furnace, and is fed into the furnace in the order of scrap, Si, starter block and scrap steel briquette. After the molten iron is melted, C, Mn, Cu, Ni, Mo, and Cr are added in batches;

[0050] S3: Sampling of molten iron, calculate the amount of alloy that needs to be added, and add the alloy to the electric furnace. After the molten iron in the electric furnace is completely dissolved, it is necessary to take multiple samples and analyze the composition of the sample. Until the standard is reached, then carry out h...

Embodiment 3

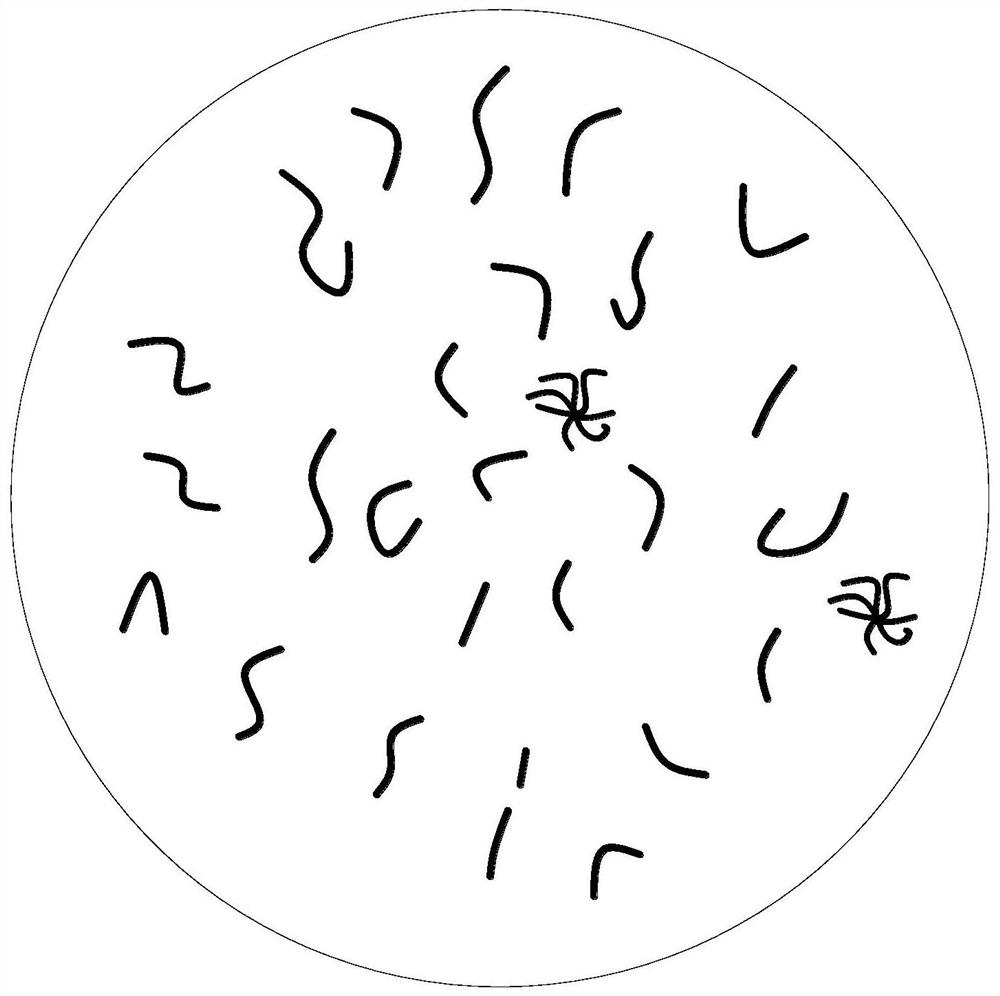

[0058] see figure 2 , a method for casting high matrix hardness GM241 alloy gray iron, comprising the following steps:

[0059] S1: GM241 alloy gray iron is composed of C: 3.0%, Si: 1.6%, Mn: 0.9%, P: 0.06%, S: 0.1%, Cu: 0.3%, Ni: 0.10%, Mo: 0.4% and Cr: 0.4 % composition, GM241 alloy gray iron graphite length 50um, A-type graphite 90%, hardness 220~241HB, quenching hardness≧52HRC;

[0060] S2: The molten iron is dissolved in an intermediate frequency induction furnace, and is fed into the furnace in the order of scrap, Si, starter block and scrap steel briquette. After the molten iron is melted, C, Mn, Cu, Ni, Mo, and Cr are added in batches;

[0061] S3: Sampling of molten iron, calculate the amount of alloy that needs to be added, and add the alloy to the electric furnace. After the molten iron in the electric furnace is completely dissolved, it is necessary to take multiple samples and analyze the composition of the sample. Until the standard is reached, then carry out ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com