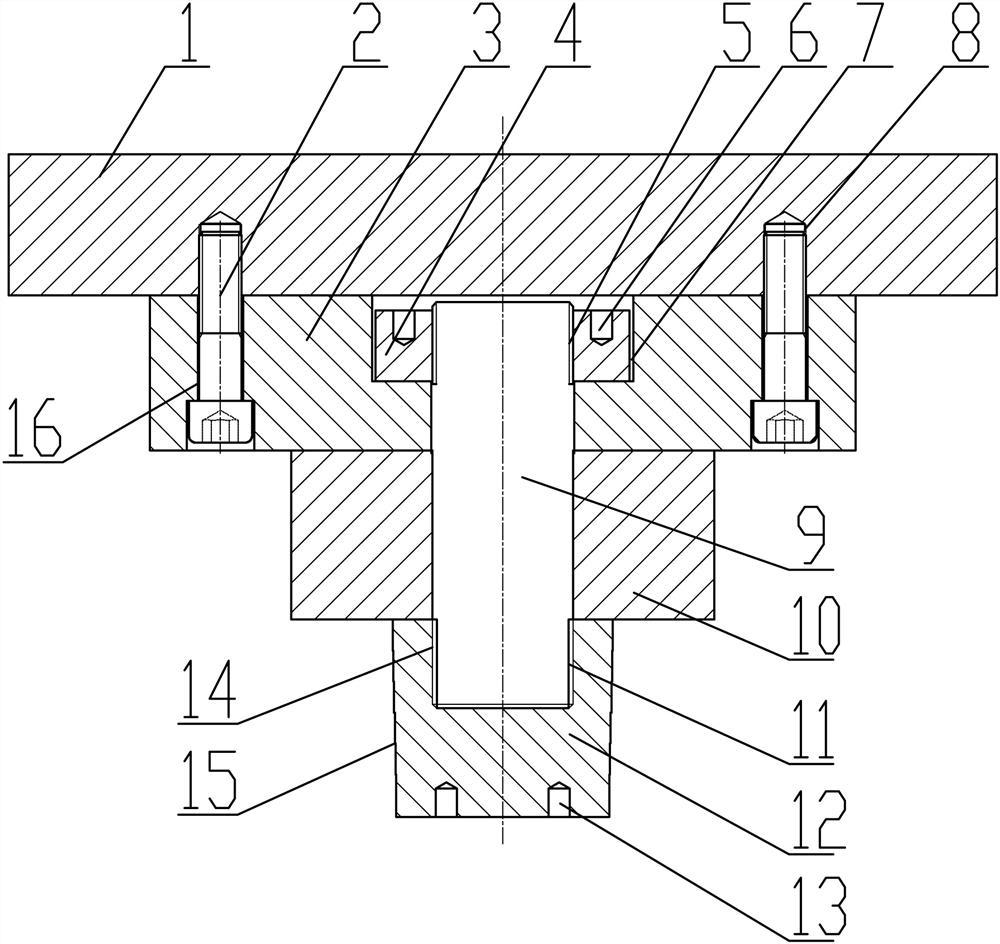

Guide sleeve hot forging forming die and assembling method

A technology of forging forming and guiding sleeve, which is applied in the direction of manufacturing tools, forging/pressing/hammer devices, forging/pressing/hammering machines, etc., can solve the problem of high mold cost, achieve easy processing, reduce processing costs, and increase service life. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 2

[0083] The assembly method of the guide sleeve hot forging molding die comprises the following steps:

[0084] The assembly process of the internal mold structure:

[0085] Step 1.1: install the nut 4 on the first externally threaded column 5 of the tie rod 9;

[0086] Step 1.2: Pass the tie rod 9 through the stepped hole 7 of the connecting flange 3;

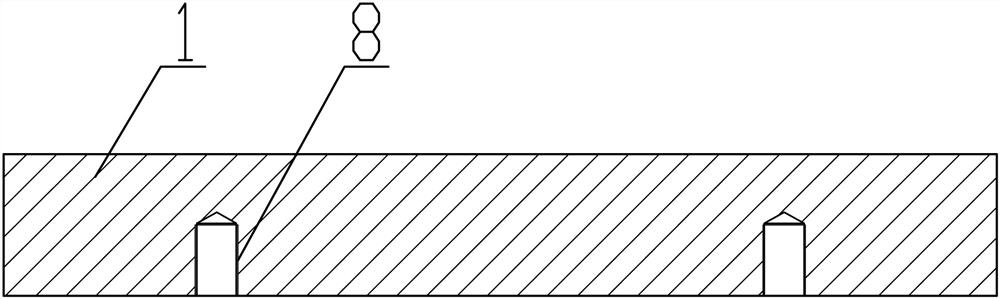

[0087] Step 1.3: Fix the connecting flange 3 on the upper mold base 1 through the flange bolt 2;

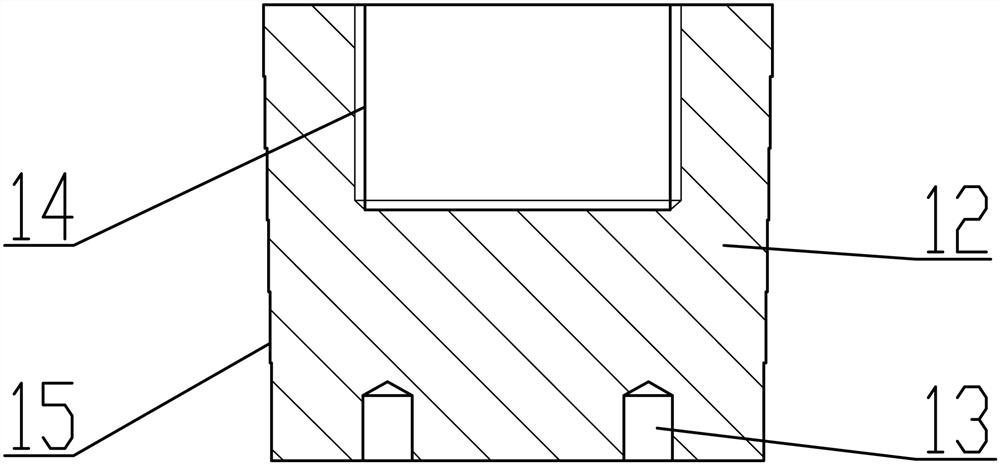

[0088] Step 1.4: Put the sleeve 10 on the pull rod 9, fix the punch 12 on the second externally threaded column 11 through threads, and lock and fix the punch 12;

[0089] The assembly process of the outer mold structure is:

[0090] Step 2.1: Align the small end of the outer ring of the mold core 28 with the big end of the inner ring of the mold sleeve 26, and then slowly press it in until the end faces of the two are aligned. the mold;

[0091] Step 2.2: Position and install the backing plate 18 in the center of the backing...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com