Continuous-casting cast rod for overlay welding of high-temperature and high-pressure valve and welding technology thereof

A high temperature and high pressure, welding process technology, applied in the field of remanufacturing, can solve the problems of corrosion, waste of resources, and high maintenance costs, and achieve the effects of avoiding waste, prolonging service life, and high hardness of the matrix

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

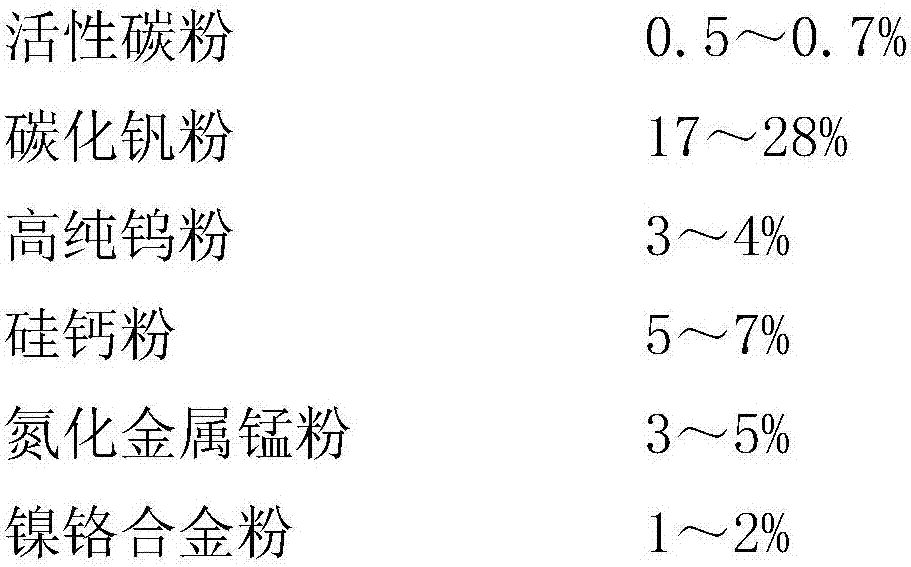

[0018] A continuous casting rod for surfacing welding of high-temperature and high-pressure valves, comprising the following components in mass percentage:

[0019]

[0020]

[0021] The vanadium carbide powder includes the following components in mass percentage: 17% of total carbon, 0.1% of free carbon, 0.5% of Fe, 0.2% of Si, and the balance of VC.

[0022] The metal manganese nitride powder includes the following components in mass percentage: N is 6.5%, C is 0.5%, Si is 1%, P is 0.1%, S is 0.05%, and Mn is the balance.

[0023] A welding process of continuous casting rods for surfacing welding of high-temperature and high-pressure valves, the welding process is: adopting an oxygen-acetylene carbonization flame welding method (manual or automatic) for surfacing welding.

[0024] Preheating treatment is carried out before surfacing, the preheating temperature is 300 ℃, and the temperature between surfacing layers is 250 ℃.

[0025] Stress relief heat treatment should...

Embodiment 2

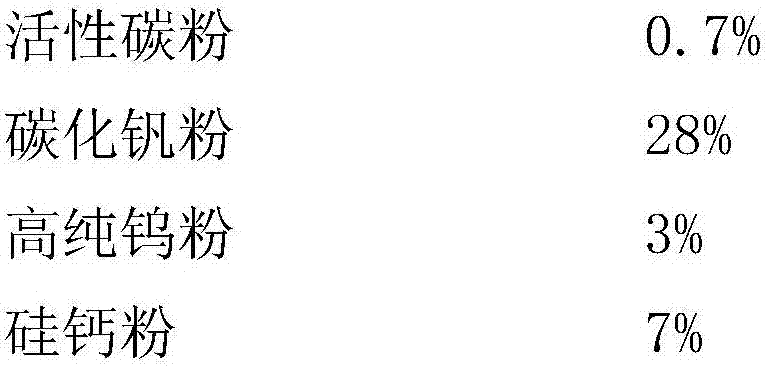

[0027] A continuous casting rod for surfacing welding of high-temperature and high-pressure valves, comprising the following components in mass percentage:

[0028]

[0029] The vanadium carbide powder includes the following components in mass percentage: 19% of total carbon, 0.05% of free carbon, 0.1% of Fe, 0.5% of Si, and the balance of VC.

[0030] The metal manganese nitride powder includes the following components in mass percentage: N is 9.0%, C is 0.1%, Si is 0.5%, P is 0.2%, S is 0.1%, and Mn is the balance.

[0031] A welding process of continuous casting rods for surfacing welding of high-temperature and high-pressure valves, the welding process is: adopting an oxygen-acetylene carbonization flame welding method (manual or automatic) for surfacing welding.

[0032] Preheating treatment is carried out before surfacing, the preheating temperature is 250 ℃, and the temperature between surfacing layers is 250 ℃.

[0033] Stress relief heat treatment should be carrie...

Embodiment 3

[0035] A continuous casting rod for surfacing welding of high-temperature and high-pressure valves, comprising the following components in mass percentage:

[0036]

[0037] The vanadium carbide powder includes the following components in mass percentage: 18% of total carbon, 0.1% of free carbon, 0.5% of Fe, 0.5% of Si, and the balance of VC.

[0038] The metal manganese nitride powder includes the following components in mass percentage: N is 7.3%, C is 0.4%, Si is 0.8%, P is 0.15%, S is 0.1%, and Mn is the balance.

[0039] A welding process of continuous casting rods for surfacing welding of high-temperature and high-pressure valves, the welding process is: adopting tungsten argon arc welding (manual or automatic) for surfacing welding.

[0040] Preheating treatment is carried out before surfacing, the preheating temperature is 350°C, and the interlayer temperature of surfacing is 250°C.

[0041] Stress relief heat treatment should be carried out immediately after the w...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com