Tantalum-tungsten alloy foil preparation method and tantalum-tungsten alloy foil

A tantalum-tungsten alloy and foil technology, which is applied in the preparation of tantalum-tungsten alloy foils and in the field of tantalum-tungsten alloy foils, can solve the problems such as the processing technology of tantalum-tungsten alloy foils, the reduction of crystalline alloy plasticity, and the difficulty of foil preparation, etc. problem, to achieve the effect of grain refinement, uniform organization, and dimensional accuracy.

Active Publication Date: 2019-10-01

CENT SOUTH UNIV

View PDF4 Cites 0 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

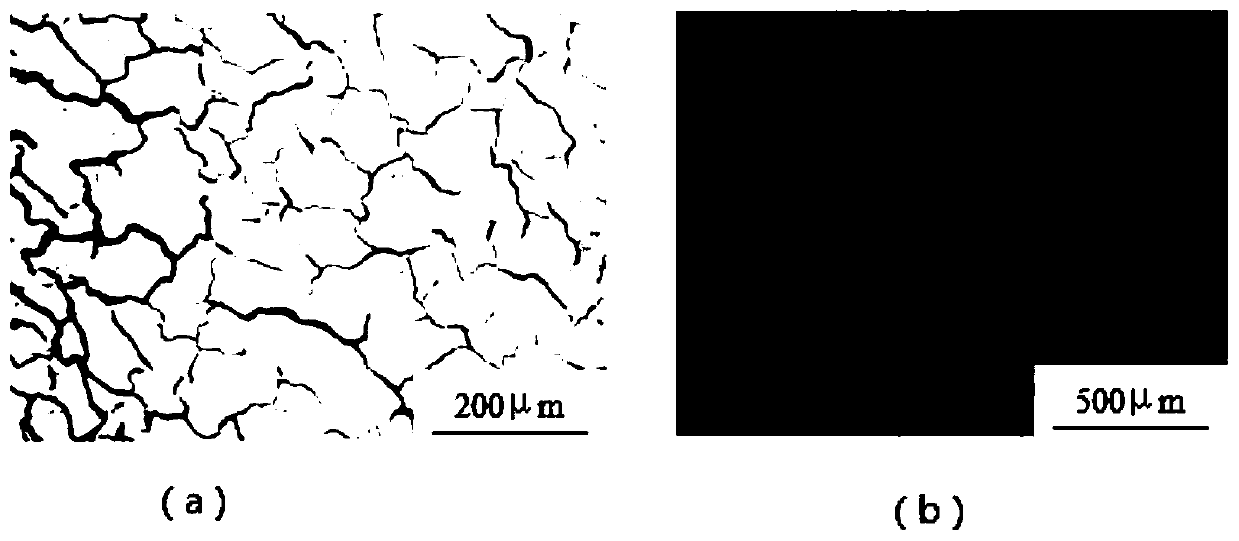

But when it exceeds 12% to 14% (atomic fraction), the plasticity of the recrystallized alloy will be significantly reduced, its processing performance will be significantly deteriorated, and the preparation of the foil will become extremely difficult. So far, no tantalum-tungsten alloy foil with a tungsten content of more than 10.0% has been seen. material processing technology

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment 1

Embodiment 2

Embodiment 3

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Login to View More

Abstract

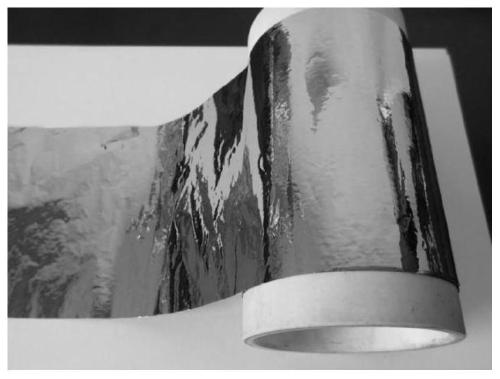

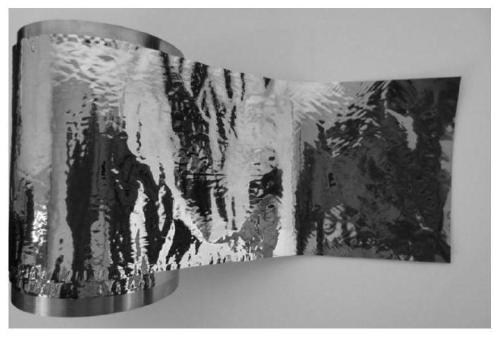

The invention discloses a method for preparing a tantalum-tungsten alloy foil, which comprises the following steps: mixing tungsten powder and tantalum powder to obtain a mixed powder, wherein the mass percentage of the tungsten powder is 10.0-11.5%, and the tungsten powder includes a particle size of 1 ‑3μm, 3‑5μm, 5‑7μm tungsten powder; the mixed powder is cold-pressed and vacuum sintered to obtain a sintered ingot; then vacuum vertical melting is performed to obtain a vertical melting ingot; the vertical melting ingot is Carry out stainless steel sheathing in the argon chamber; at the preset billet opening temperature, forge and open the vertically melted ingot after step 4; remove the stainless steel sheathing on the surface of the ingot, and alternately perform multi-pass cold rolling deformation and annealing Processing, when the ingot is cold-rolled and deformed to a thickness of 0.01mm, the surface is cleaned; vacuum annealing and tensioned cold-rolling deformation are carried out to obtain a foil with a thickness of less than 7 μm; the foil is wound on a cast iron pipe for vacuum annealing, and naturally After cooling, the required tantalum-tungsten alloy foil is obtained; the tantalum-tungsten alloy foil has high tungsten content and thin thickness.

Description

technical field The invention relates to the technical field of metal alloy preparation, in particular to a method for preparing a tantalum-tungsten alloy foil and the tantalum-tungsten alloy foil. Background technique Tantalum-tungsten (Ta-W) alloy is widely used because of its high density, high melting point, high elastic modulus, high ductility, good processing performance, high temperature strength, corrosion resistance, weldability and low plastic-brittle transition temperature. Widely used in aerospace, national defense, chemical and nuclear industries and other fields. Adding tungsten to tantalum can form a solid solution alloy, which plays a role in solid solution strengthening and grain refinement. With the increase of tungsten content, the performance of tantalum-tungsten alloy at room temperature and high temperature will be significantly improved. With the development of industries such as electric vacuum, electronics and nuclear energy, high-strength, ultra-...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More Patent Type & Authority Patents(China)

IPC IPC(8): B22F1/00B22F3/10B22F3/17B22F3/18B22F3/24B22F5/00C22C27/02C22C1/04

CPCC22C1/045C22C27/02B22F3/1007B22F3/1035B22F3/17B22F3/18B22F3/24B22F5/006B22F2999/00B22F2998/10B22F2003/248B22F1/052B22F2201/20B22F3/02

Inventor 李周肖柱龚深方梅邱文婷

Owner CENT SOUTH UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com