A kind of preparation method of tungsten trioxide/graphene composite negative electrode material

A technology of negative electrode material and mixed solution, which is applied in the field of preparation of WO3/RGO composite negative electrode materials, can solve the problems of large particle size of composite materials, great influence on electrochemical performance, and low content of tungsten in composite materials, and achieve uniform and fine particles , good electrochemical performance, and less volume change

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

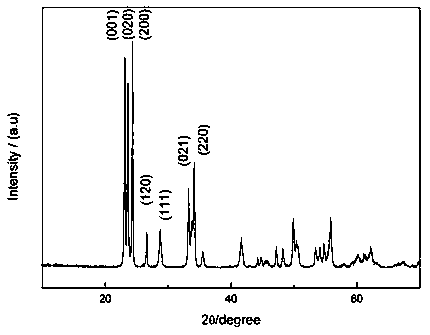

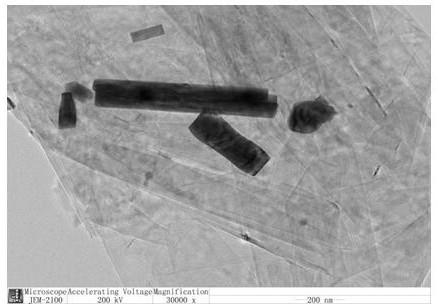

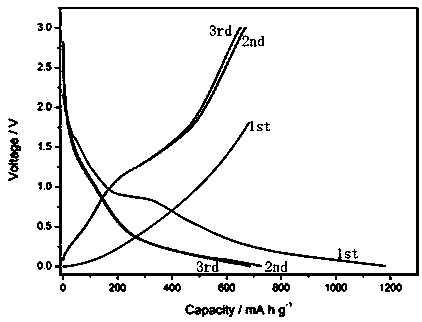

[0024] WO described in this example 3 The preparation method of / RGO composite negative electrode material specifically comprises the following steps:

[0025] (1) Mix 200mg of ammonium metatungstate and 20mg of RGO (mass ratio is 10:1), then add it to 10mL of 1mol / L dilute hydrochloric acid and 60mL of diethylene glycol to prepare a mixed solution, and use ultrasonic vibration (oscillation frequency 40KHZ) to disperse the solution for 50 minutes, transfer the solution to a reaction kettle with a polytetrafluoroethylene liner, heat it to 140°C for 18 hours, and cool it down to room temperature naturally.

[0026] (2) Pour out the mixture in the reaction kettle, filter it, wash the precipitate several times with deionized water and alcohol, and dry it in a drying oven at 40°C for 24 hours.

[0027] (3) Place the dried powder in step (2) in a microwave oven, rapidly heat it up to 400°C at a heating rate of 5°C / min, keep it warm for 100 minutes, and cool it down to room tempera...

Embodiment 2

[0033] WO described in this example 3 The preparation method of / RGO composite negative electrode material specifically comprises the following steps:

[0034] (1) Take 300mg of ammonium metatungstate and mix 20mg of RGO (mass ratio is 15:1), then add it to 10mL of 1mol / L dilute hydrochloric acid and 100mL of diethylene glycol to prepare a mixed solution, and use ultrasonic vibration (oscillation frequency 40KHZ) to disperse the solution for 30 minutes, transfer the solution to a reaction kettle with a polytetrafluoroethylene liner, heat it to 180°C for 24 hours, and cool it down to room temperature naturally.

[0035] (2) Pour out the mixture in the reaction kettle, filter, wash the precipitate several times with deionized water and alcohol, and dry it in a drying oven at 45°C for 24 hours.

[0036] (3) Place the dried powder in step (2) in a microwave oven, rapidly heat it up to 500°C at a heating rate of 9°C / min, keep it warm for 120 minutes, and cool it down to room temp...

Embodiment 3

[0042] WO described in this example 3 The preparation method of / RGO composite negative electrode material specifically comprises the following steps:

[0043] (1) Take 400mg of ammonium metatungstate and mix 20mg of RGO (mass ratio is 20:1), then add it to 10mL of 1mol / L dilute hydrochloric acid and 120mL of diethylene glycol to prepare a mixed solution, and use ultrasonic vibration (oscillation frequency 40KHZ) to disperse the solution for 30 minutes, transfer the solution to a reaction kettle with a polytetrafluoroethylene liner, heat it to 180°C for 30 hours, and cool it down to room temperature naturally.

[0044] (2) Pour out the mixture in the reaction kettle, filter, wash the precipitate several times with deionized water and alcohol, and dry it in a drying oven at 45°C for 24 hours.

[0045] (3) Put the dried powder in step (2) in a microwave oven, rapidly heat it up to 550°C at a heating rate of 10°C / min, keep it warm for 120 minutes, and cool it down to room tempe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com