Preparation method and preparation equipment of tungsten-copper alloy

A tungsten-copper alloy and equipment technology, which is applied in the field of tungsten-copper alloy preparation, can solve the problems of high production cost, long process flow, large porosity of tungsten-copper alloy skeleton, etc., and achieve the effect of ensuring quality and simple process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

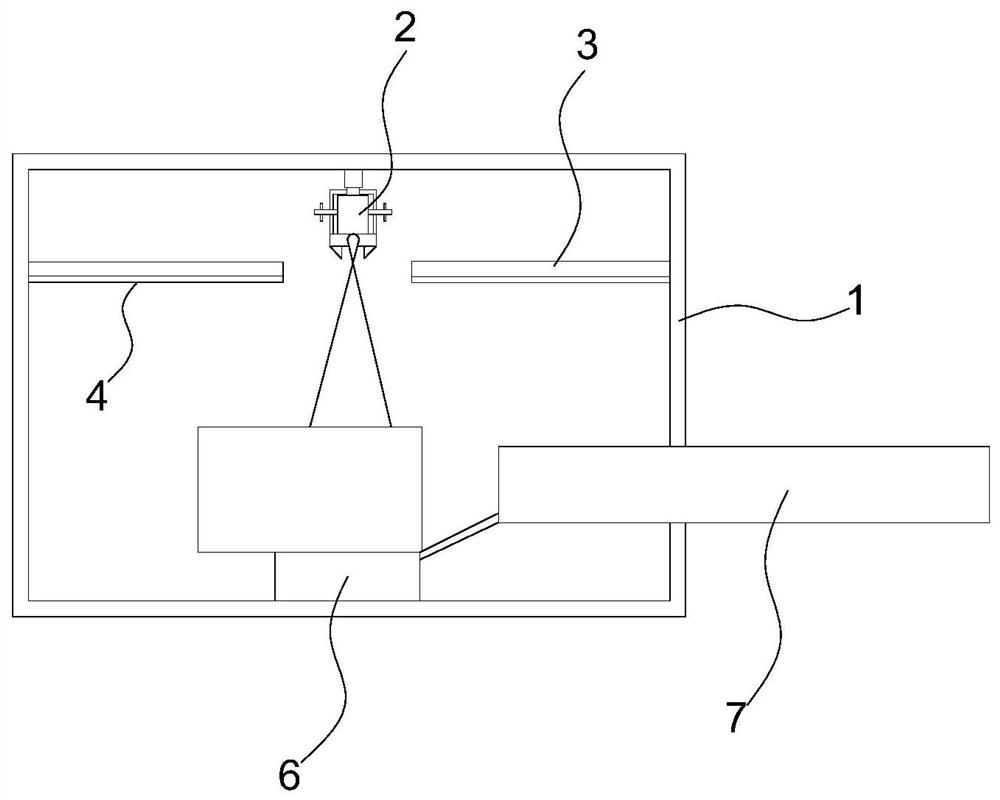

[0022] Such as figure 1 As shown, the preparation equipment for tungsten-copper alloy includes an electron beam melting furnace 1, an electron gun assembly 2 is arranged on the top of the electron beam melting furnace 1, a raw material placement mechanism 6 is arranged at the bottom, and a feeding mechanism 7 is arranged on the side wall. The discharge end of the feeding mechanism 7 is connected to the raw material placing mechanism 6 .

[0023] The electron gun assembly 2 includes an electron gun and a rotating seat on which the electron gun is installed. The electron gun is a cold-cathode electron gun with a maximum power of 600kw and a melting temperature of up to 10,000°C. The rotating seat can rotate within a certain range so that the electron gun can perform circular scanning. The raw material placing mechanism 6 is used to place the raw material, and a crucible can be used, and its position corresponds to that of the electron gun, so as to ensure that the electron beam ...

Embodiment 2

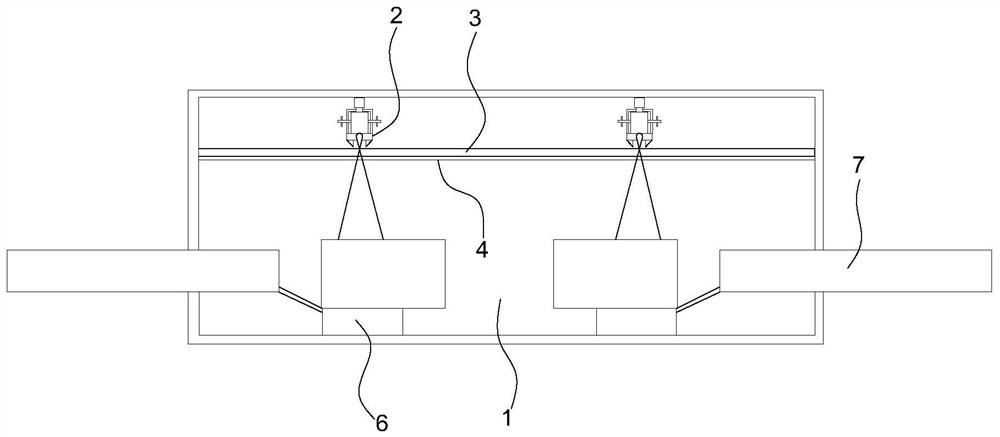

[0031] Such as figure 2 As shown, the preparation equipment for tungsten-copper alloy includes an electron beam melting furnace 1, two electron gun assemblies 2 are arranged on the top of the electron beam melting furnace 1, two raw material placement mechanisms 6 are arranged on the bottom, and two Feeding mechanism 7 , the discharge end of each feeding mechanism 7 is connected with a raw material placement mechanism 6 , and each raw material placement mechanism 6 is located below an electron gun assembly 2 . The structures and functions of the electron gun assembly 2, the raw material placing mechanism 6 and the feeding mechanism 7 are the same as those in the first embodiment.

[0032] When preparing copper-tungsten alloy, put the copper raw material and the tungsten raw material into the two raw material placement mechanisms 6 of the electron beam melting furnace 1 at the same time, and there is a certain distance between the two raw material placement mechanisms 6, so th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com