A metal frame toughened ceramic composite material and its preparation method and application

A metal frame and toughened ceramic technology, applied in the field of wear-resistant materials, can solve the problems of affecting the quality of castings, high brittleness of composite materials, and high cost, and achieve the effects of low production cost, good interface bonding, and improved performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

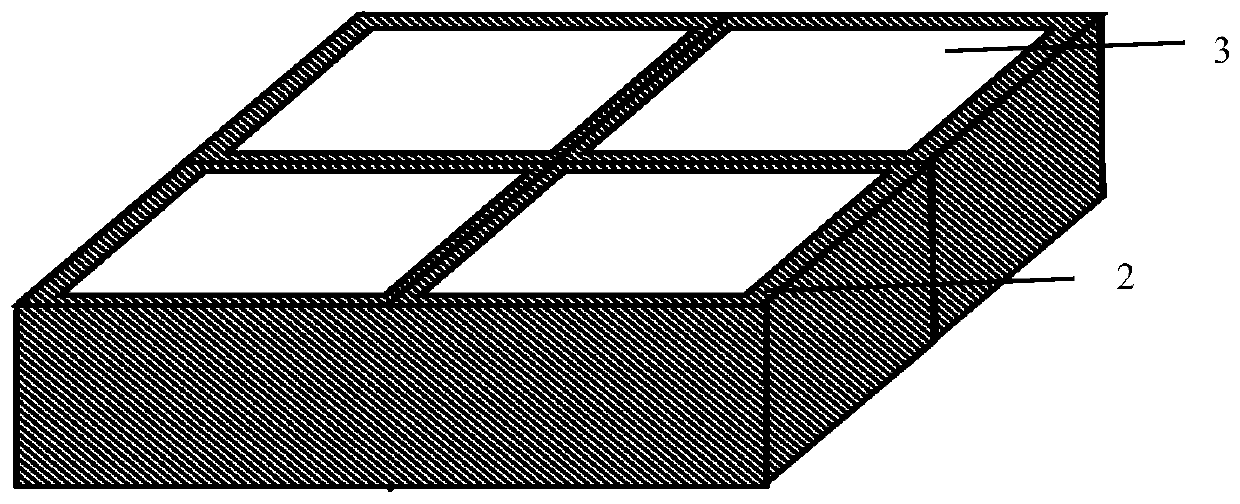

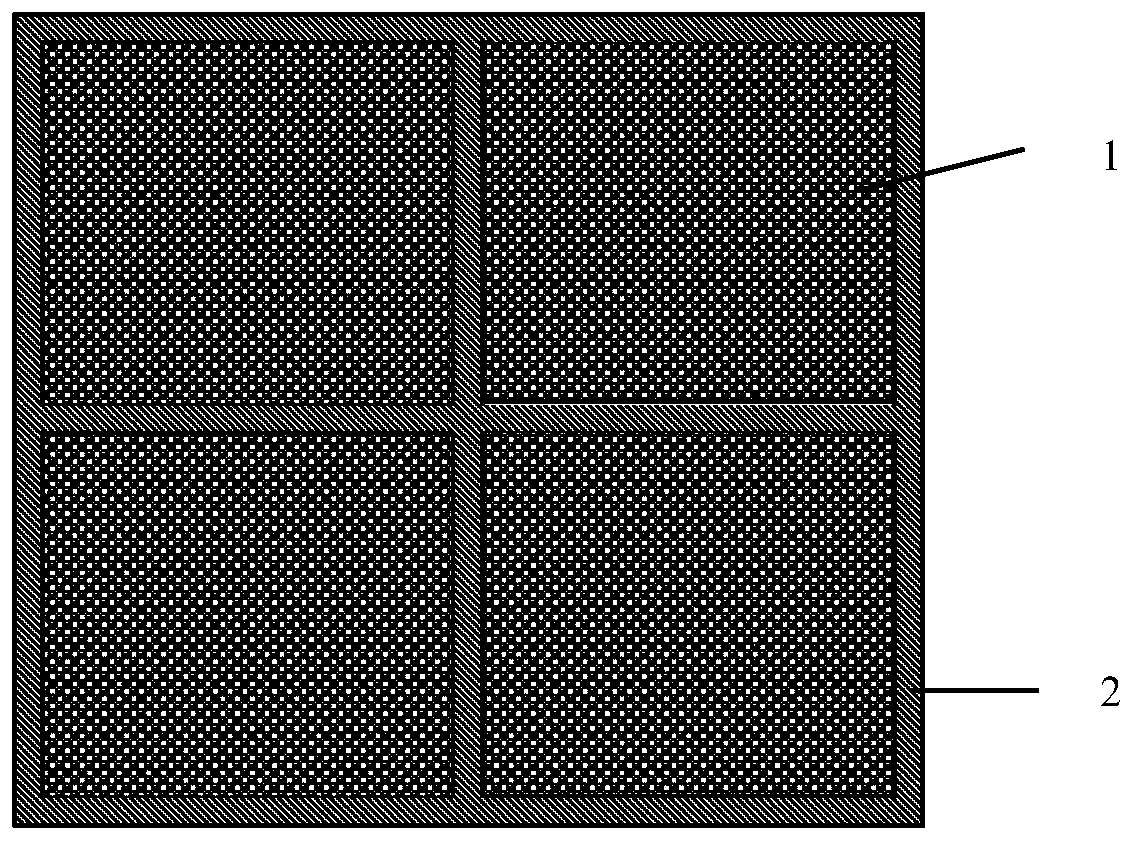

[0087]A metal frame toughened ceramic composite material, in which a plurality of honeycomb cavities are arranged, and the cavities are tetragonal. The metal frame toughened ceramic composite material is used for the lining board of a vertical mill, which includes an external metal frame, a tetragonal Ceramic particle reinforced metal powder reinforced composite block, the metal frame toughened ceramic composite material is set in the working area of the vertical mill lining board, the casting material is high wear-resistant alloy powder; the thickness of the working area is the overall vertical mill lining 1 / 2 of the plate height;

[0088] The metal frame toughened ceramic composite material includes ceramic particles and matrix powder tetragonal compression reinforced composite block 1, and the reserved area inside the cavity is a tetragonal outer metal frame 2; wherein, ceramic particles and matrix powder tetragonal compression The reinforced composite block 1 is set in t...

Embodiment 2

[0113] A metal frame toughened ceramic composite material, in which a plurality of honeycomb cavities are arranged, and the cavity is a cylinder. The metal frame toughened ceramic composite material is used for vertical mill roller sleeves, which includes an external metal frame, cylindrical ceramic particles Reinforce the metal powder to reinforce the composite block, set the metal frame toughened ceramic composite material in the roller sleeve of the vertical mill, and the casting material used is high wear-resistant alloy powder; the thickness of the working area is 1 / 3 of the height of the overall vertical mill roller sleeve;

[0114] The metal frame toughened ceramic composite material includes ceramic particles and matrix powder cylindrical compression reinforced composite block 4, and the reserved area inside the cavity is an external metal frame 6 in the reserved area of the cylinder; wherein, the ceramic particles and the matrix The powder cylindrical compression rei...

Embodiment 3

[0139] A metal frame toughened ceramic composite material, in which a plurality of honeycomb cavities are arranged, and the cavity is a hexagonal prism. Prismatic ceramic particles reinforced metal powder reinforced composite block, the metal frame toughened ceramic composite material is set in the working area of the vertical mill roller sleeve, and the casting material is high wear-resistant alloy powder; the thickness of the working area is the height of the overall vertical mill roller sleeve 1 / 2 of

[0140] The metal frame toughened ceramic composite material comprises a hexagonal prism compression reinforced composite block, an external metal frame of a hexagonal prism is arranged inside the cavity, and the hexagonal prism compression reinforced composite block is arranged in the external metal frame Hexagonal prism reserved area; the ceramic particles are white corundum particles + Cr 7 C 3 Particles are used as a reinforcing phase, and the volume ratio is reinforce...

PUM

| Property | Measurement | Unit |

|---|---|---|

| hardness | aaaaa | aaaaa |

| hardness | aaaaa | aaaaa |

| particle size (mesh) | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com