Protecting, cooling and chip collecting device used when laser cutting inner wall of cylinder and using method thereof

A laser cutting and cylinder-in-body technology, applied in laser welding equipment, welding equipment, metal processing equipment, etc., can solve the problems of human health injury, narrow cutting seam, no mechanical stress, etc., achieve easy operation, convenient cleaning, and prevent injury Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

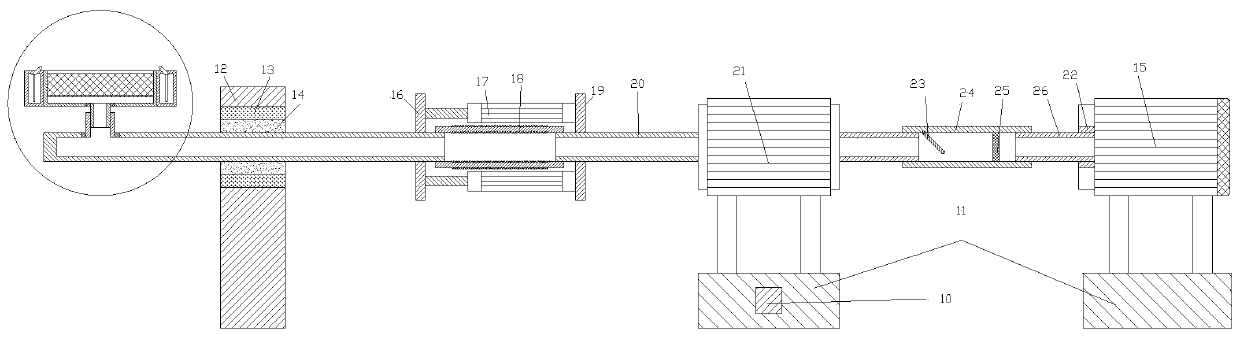

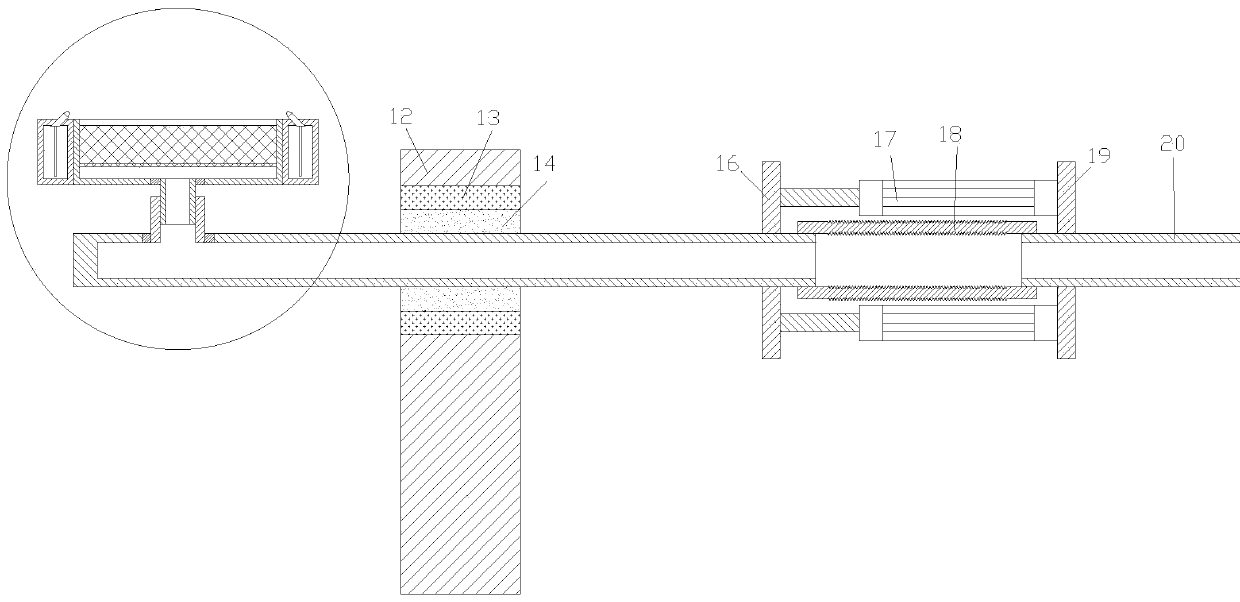

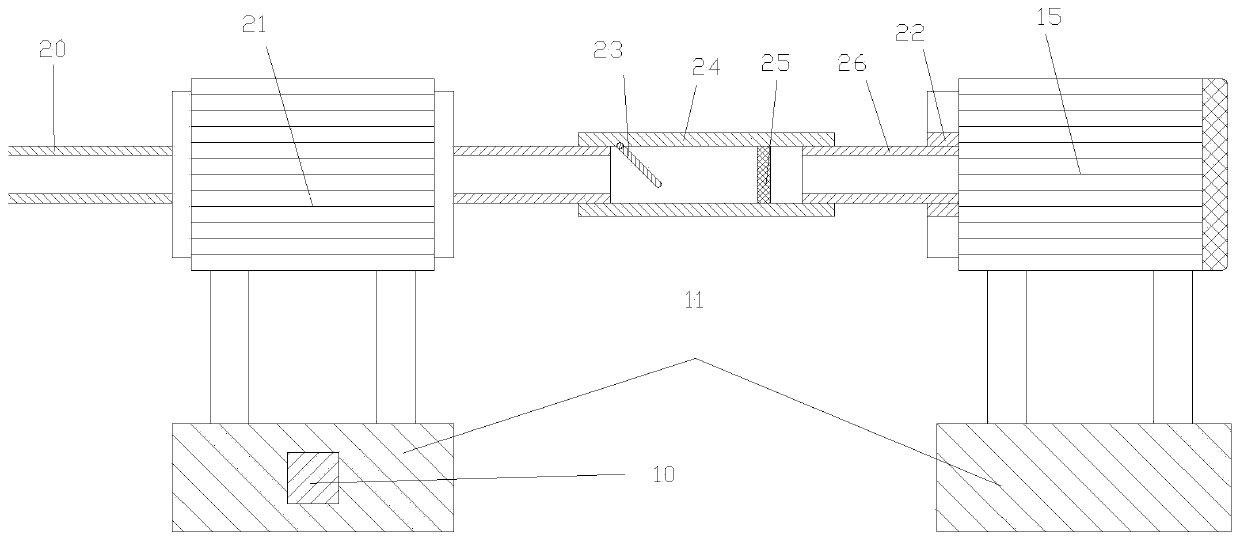

[0018] The present invention will be further explained below in conjunction with the drawings:

[0019] Reference attached figure 1 , 2 , 3, 4, 5, 6, 7: The laser cutting inner wall protection and cooling chip collecting device of the cylinder in this embodiment includes a splicing pipe 1, and the splicing pipe 1 is threadedly connected to the inner wall of the top left half of the splicing pipe 1 2. The bottom of the connecting pipe 2 is connected to the inside of the splicing pipe 1. A U-shaped box 9 is provided above the connecting pipe 2, and a U-shaped cavity 7 is provided in the U-shaped box 9 and the top of the U-shaped cavity 7 is provided. There is a cooling mesh 8, the top of the cooling mesh 8 communicates with the outside, the bottom of the U-shaped cavity 7 is screwed with an adjusting tube 3, the top of the adjusting tube 3 communicates with the U-shaped cavity 7, and the bottom of the adjusting tube 3 Threaded connection with the top of the connecting pipe 2, the b...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com