Microcrystalline glass and preparation method thereof

A glass-ceramic and micro-crystal technology, applied in the field of glass-ceramic and its preparation, can solve the problems of affecting the decorative effect and service life, cannot be used at high temperature, scratched or worn, etc., so as to overcome the problem of scratches and prolong the The effect of long service life and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

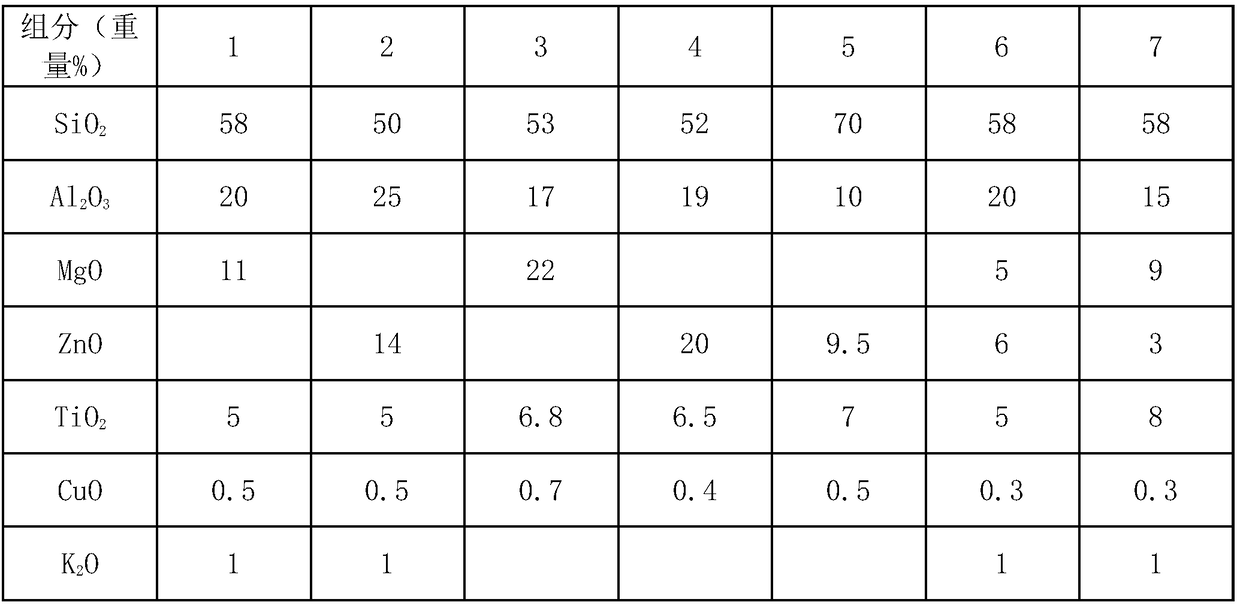

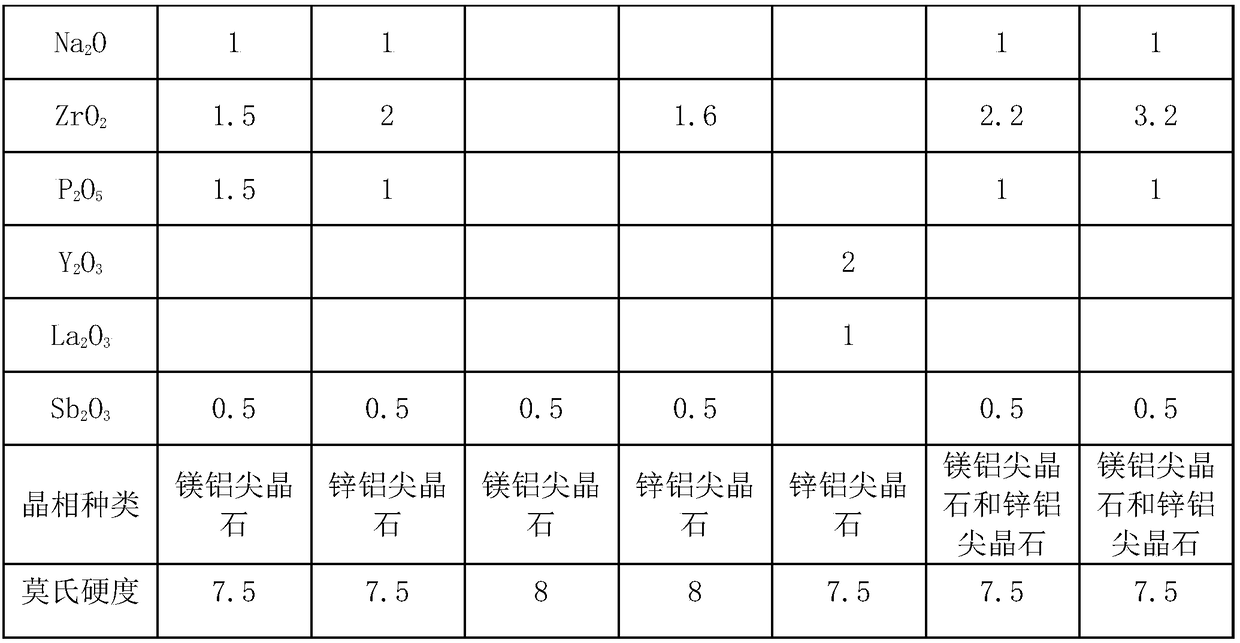

[0028] The present invention uses ZnO(MgO)-Al 2 o 3 -SiO 2 -TiO 2 -CuO is the system, the precursor glass is prepared through the melting process, and the precursor glass is annealed and heat-treated to prepare the amber glass-ceramics. The content in weight percent and its effect will be described below.

[0029] SiO 2 、Al 2 o 3 , MgO or ZnO are the main components constituting glass-ceramic of the present invention, according to MgO (or ZnO)-Al 2 o 3 -SiO 2 phase diagram, in the present invention, SiO 2 The content of Al is 50-70%; Al 2 o 3 The content of MgO is 10-25%; the content of MgO is 0-22%, and the content of ZnO is 0-20%. In the present invention, at least one of the components in MgO and ZnO is contained, further, MgO and ZnO The total content is 5-22%, preferably 8-15%. When the contents of MgO and ZnO exceed the above range, other crystals will appear in the glass, which cannot meet the requirements of the present invention. SiO 2 and Al 2 o 3 Th...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Mohs hardness | aaaaa | aaaaa |

| Mohs hardness | aaaaa | aaaaa |

| Mohs hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com