Front spraying device for automobile sealing strip

A technology for automotive sealing strips and spraying devices, applied in spraying devices, devices for coating liquid on surfaces, coatings, etc., can solve problems such as deformation and scratches, high energy consumption, and rising production costs, and prevent sagging accumulation and the effects of deformation problems

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0032] It should be noted that, in the case of no conflict, the embodiments of the present invention and the features in the embodiments can be combined with each other.

[0033] The present invention will be described in detail below with reference to the accompanying drawings and examples.

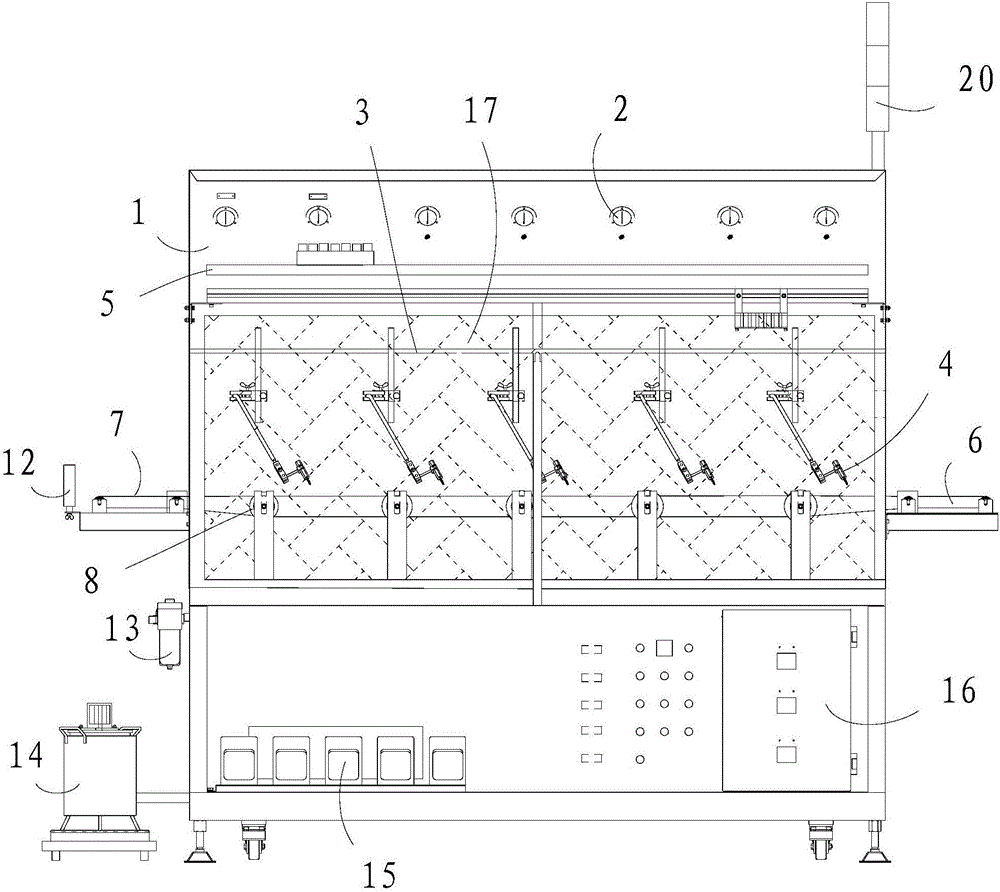

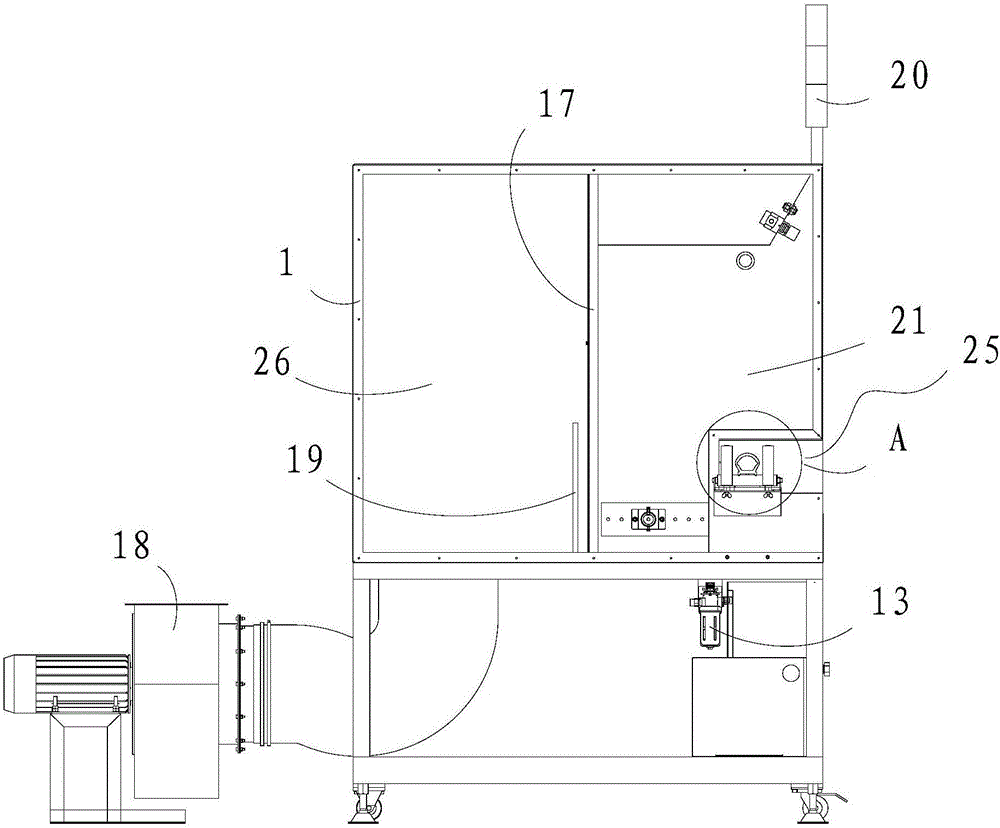

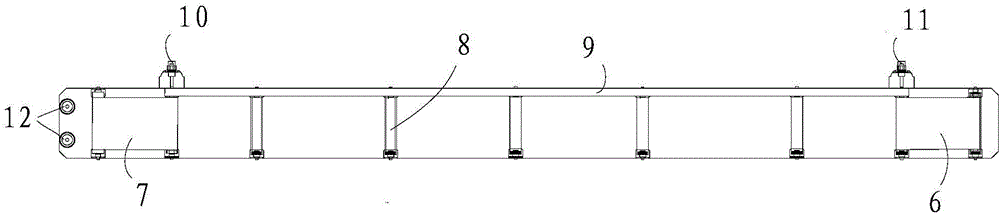

[0034] The invention relates to a pre-spraying device for automobile sealing strips, which can spray the sealing strips extruded by an extruder before the vulcanization process, so as to realize the implementation of the pre-spraying process for softer automobile sealing strips. The front spraying device for automobile sealing strips of the present invention comprises a box body, on which a spraying channel with an inlet and an outlet is arranged, and an exhaust mechanism is arranged in communication with the spraying channel, and the front spraying device also includes a spraying channel with a spray gun. mechanism, the spray gun is arranged in the spray channel, and two synchronous tra...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com