Superhard blade with chip breaking groove

A super-hard insert and chip breaker technology, which is applied to tools for lathes, accessories of tool holders, turning equipment, etc., can solve the problems of difficult chip breaking, low processing efficiency, tool chipping, etc. The effect of the probability of abrasion damage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

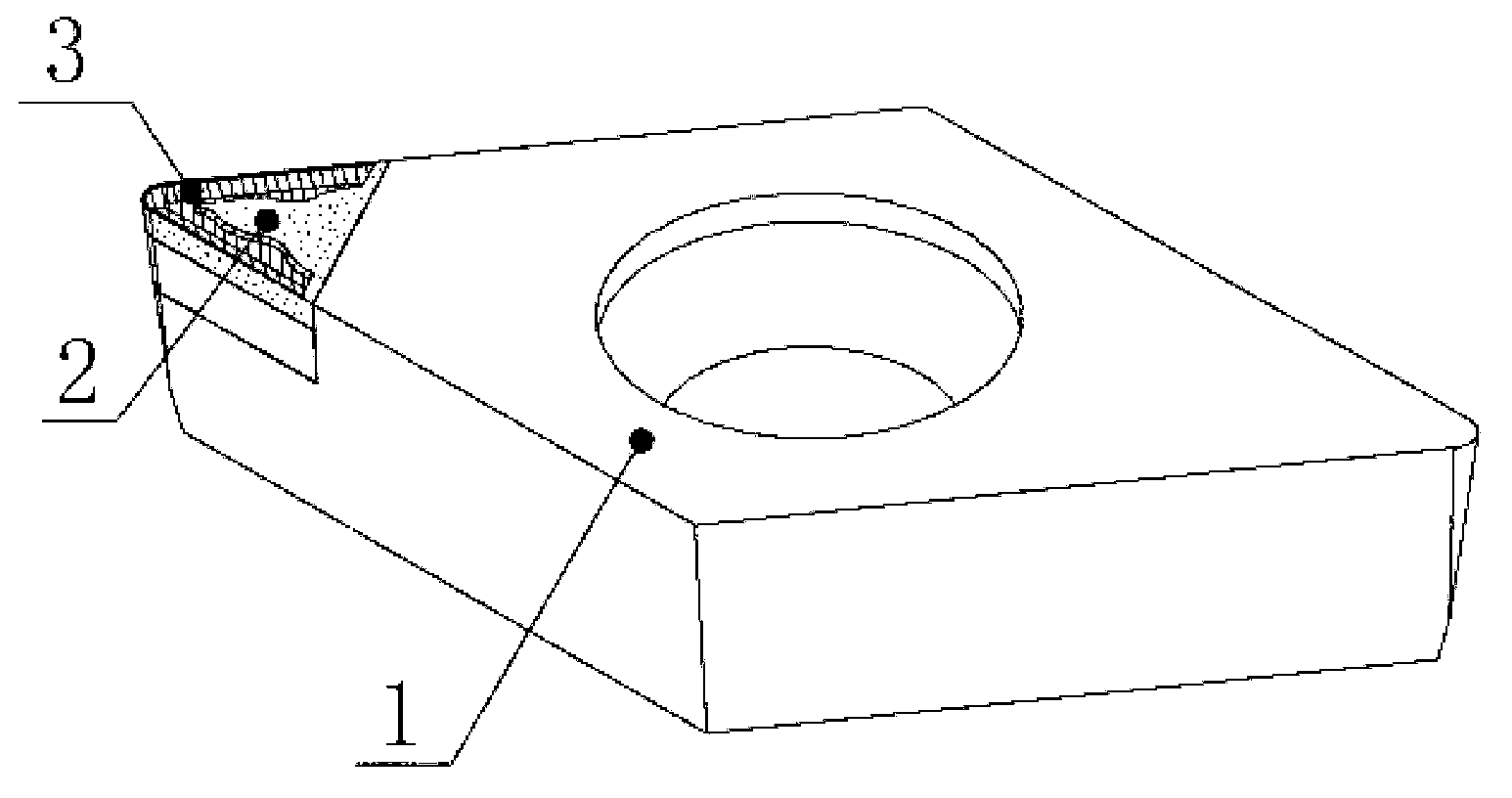

[0021] Embodiment 1: as figure 1 As shown, the shape of the blade is rectangular, which is a D-type blade in the ISO standard. The cutter head 2 is welded on the base body 1 by brazing. On the surface of the cutter head 2, there is a cutting edge 4 at the corner of the rectangle, and the concave part behind the cutting edge 4 is a chip breaker 3. The chip breaker 3 is processed on the surface of the cutter head 2 by laser engraving.

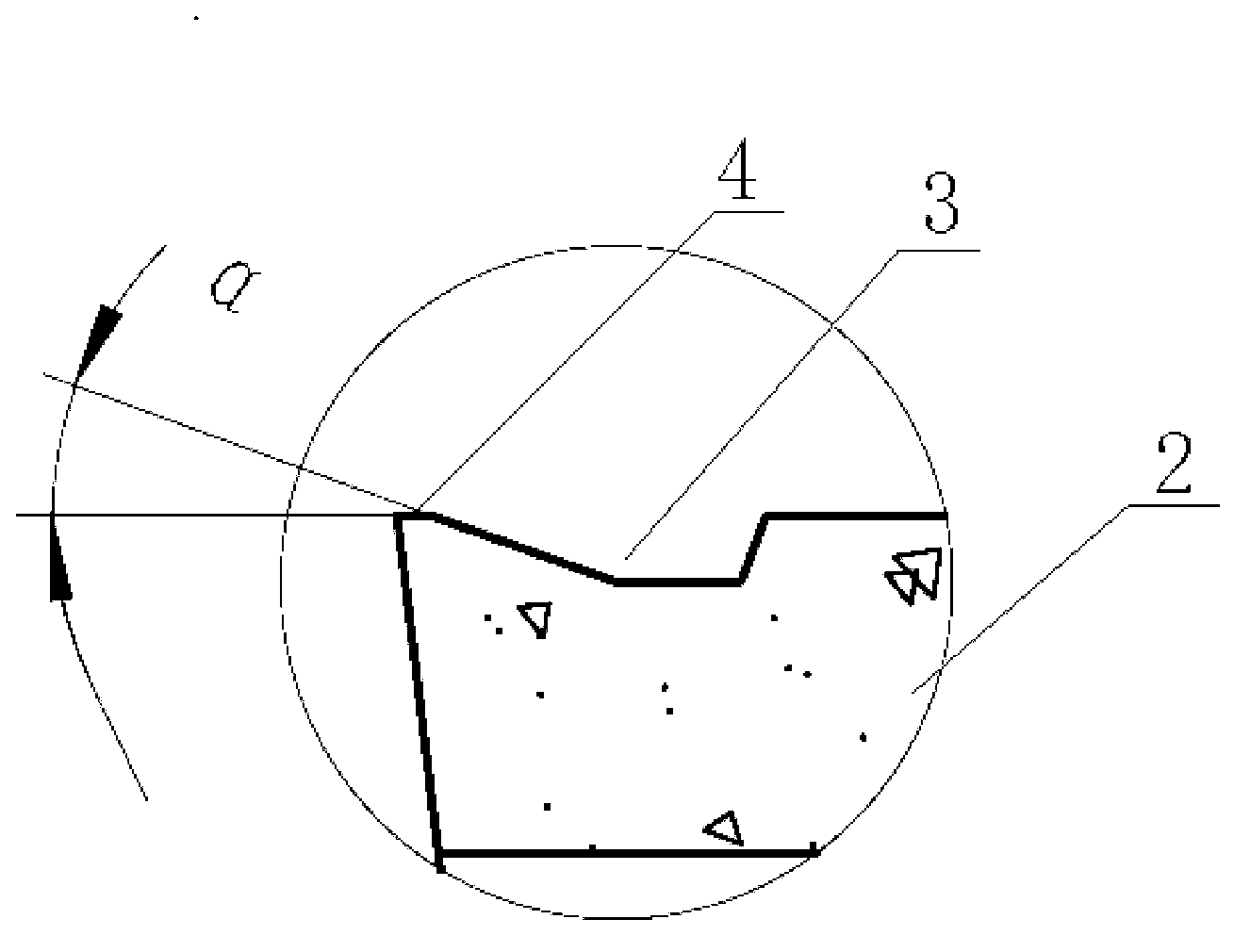

[0022] Such as figure 2 The enlargement of the figure shows that the chip breaker angle α formed between the cutting edge 4 and the chip breaker 3 ranges from 15° to 25°.

Embodiment 2

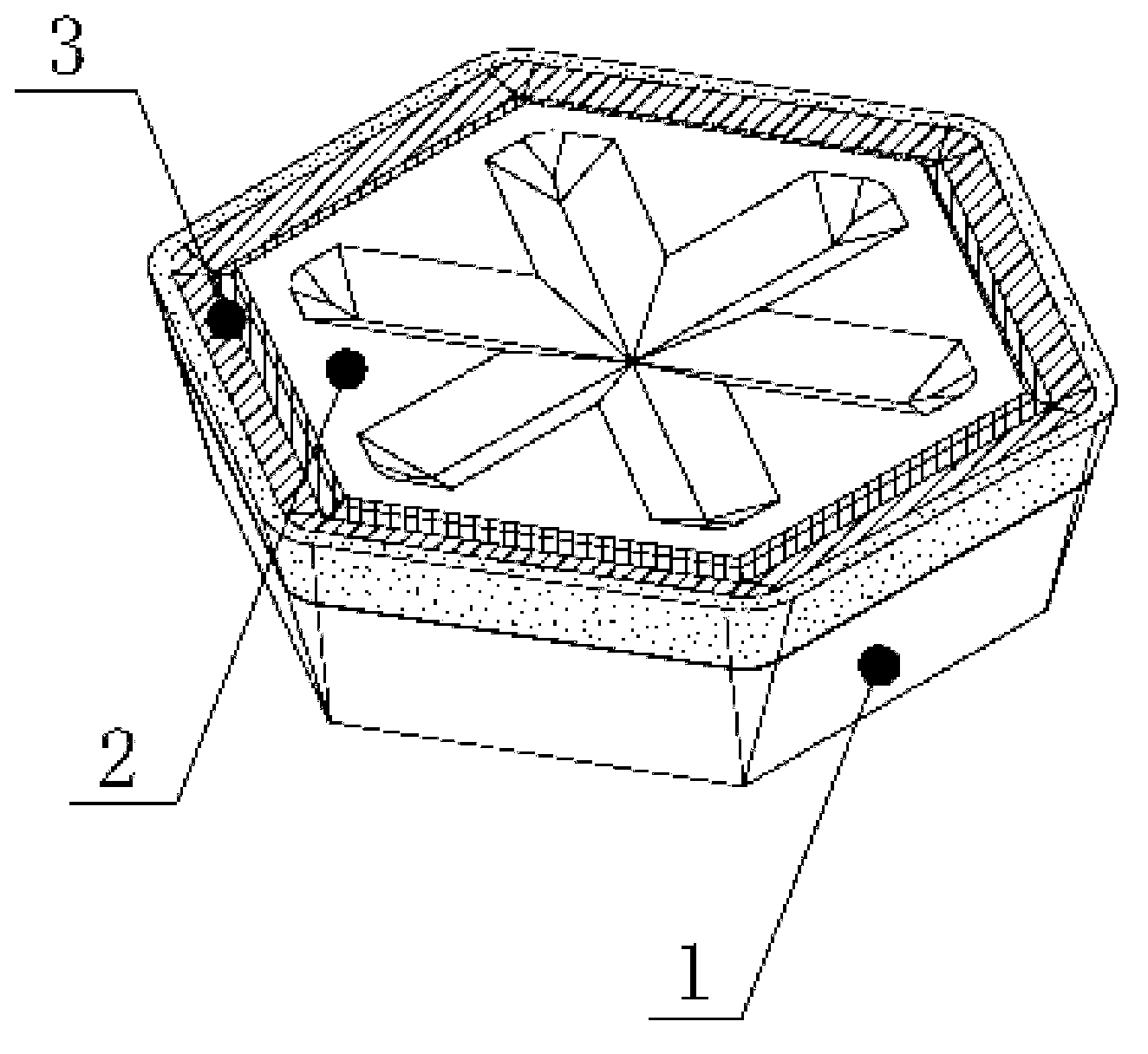

[0023] Embodiment 2: as image 3 As shown, the shape of the blade is polygonal, which is an H-type blade in the ISO standard. The cutter head 2 is welded on the base body 1 by brazing. On the surface of the cutter head 2, cutting edges 4 are arranged on the edges and corners, and the concave part behind the cutting edge 4 is a chip breaker 3. The chip breaker 3 is also processed on the surface of the cutter head 2 by laser engraving.

[0024] Such as Figure 4 As shown in the enlarged diagram of , the angle range of the chip breaker angle α formed between the cutting edge 4 and the chip breaker 3 is 15°-25°.

[0025] The blade of the present invention can be any model in the ISO standard, and can also be a special model of a customized special shape.

[0026] The head material of the superhard blade can be PCD and PCBN. PCD is mainly used for processing non-ferrous metal materials such as aluminum alloy, and PCBN is mainly used for processing materials such as hardened st...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com