Method for preparing nitrogen-phosphorus-potassium compound fertilizer from fertilizer-grade phosphoric acid eutectic

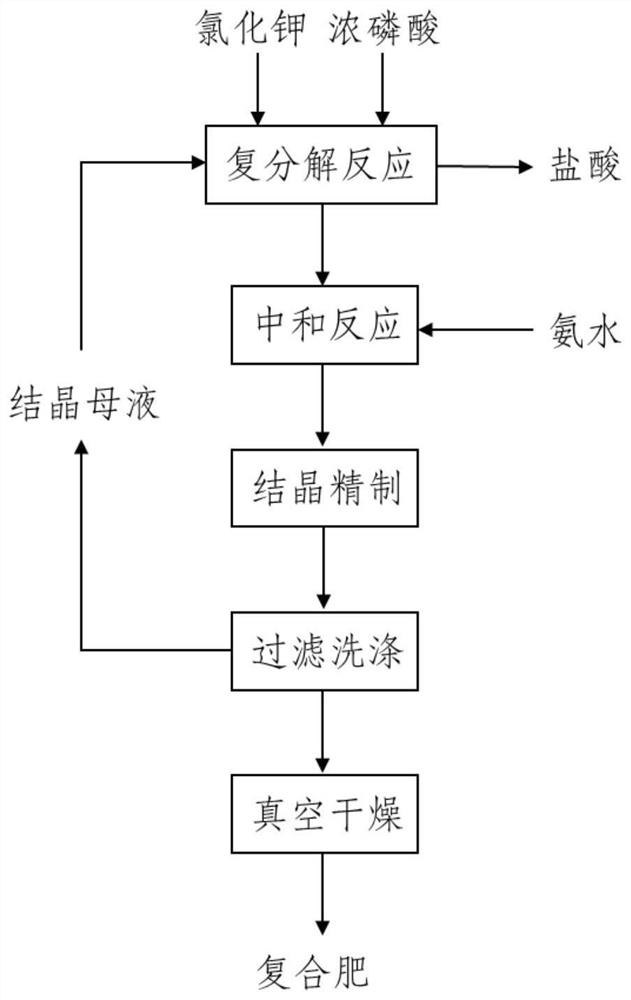

A nitrogen-phosphorus-potassium compound fertilizer and fertilizer-grade technology, which is applied in the field of chemical fertilizer preparation, can solve the problems of difficult filtration of reaction products, high cost of raw materials, and poor crystal form, and achieve high-efficiency utilization, improved conversion rate, and low chlorine content. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

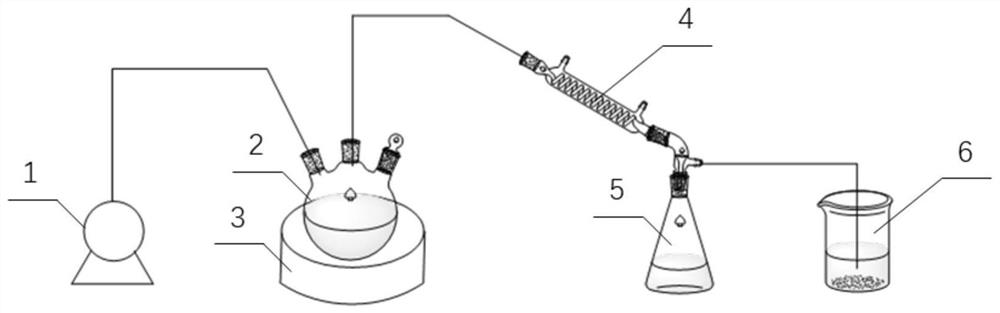

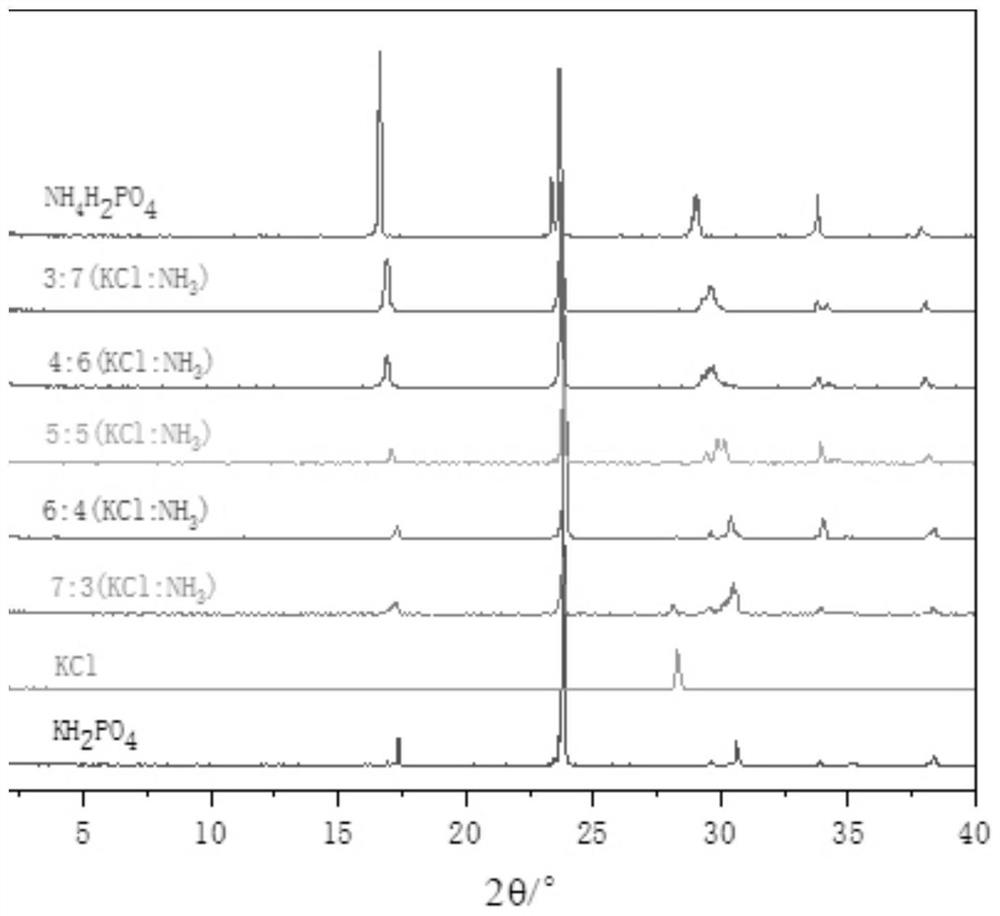

Embodiment 1

[0037]Add 64g of fertilizer-grade phosphoric acid, 30g of crystallization mother liquor and 14.5g of potassium chloride into the three-necked flask, turn on the magnetic stirring and start the air generator. Heat the oil bath to 150°C, add 25 g of water after 0.5 and 1.0 hours of reaction, and react for 1.5 hours. After the reaction, the temperature of the system was lowered to 30° C., and 26 g of concentrated ammonia water with a mass fraction of 28-30% was slowly added dropwise, and stirred for 0.5 hours. After the reaction, collect and store the by-product hydrochloric acid, transfer the solid-liquid mixture of potassium dihydrogen phosphate and ammonium dihydrogen phosphate to a crystallizer, raise the temperature to 70°C, and cool down at a rate of 0.2°C / min after the solid dissolves to 15°C. The solid-liquid mixture obtained by crystallization is centrifuged, and the solid phase is put into a vacuum drying oven to dry at 70° C. to obtain potassium dihydrogen phosphate a...

Embodiment 2

[0039] Add 64g of fertilizer-grade phosphoric acid, 30g of crystallization mother liquor and 19g of potassium chloride into the three-necked flask, turn on the magnetic stirring and start the air generator. Heat the oil bath to 160°C, add 25 g of water after 0.5, 1.0 and 1.5 hours of reaction, and react for 2.0 hours. After the reaction, the temperature of the system was lowered to 30° C., and 22 g of concentrated ammonia water with a mass concentration of 28-30% was slowly added dropwise, and stirred for 0.5 hours. After the reaction is over, collect and store the by-product hydrochloric acid, transfer the solid-liquid mixture of potassium dihydrogen phosphate and ammonium dihydrogen phosphate to the crystallizer, raise the temperature to 60°C, and dissolve the solid at a rate of 0.2°C / min Cool down to 15°C. The solid-liquid mixture obtained by crystallization is centrifuged, and the solid phase is dried in a vacuum drying oven at 70° C. to obtain potassium dihydrogen phosph...

Embodiment 3

[0041] Add 64g of fertilizer-grade phosphoric acid, 30g of crystallization mother liquor and 24g of potassium chloride into the three-necked flask, turn on the magnetic stirring and start the air generator. Heat the oil bath to 150°C, add 25 g of water after 0.5, 1.0, 1.5 and 2.0 hours of reaction, and react for 2.5 hours. After the reaction, the temperature of the system was lowered to 30° C., 18.5 g of concentrated ammonia water with a mass concentration of 28-30% was slowly added dropwise, and stirred for 0.5 hours. After the reaction, collect and store the by-product hydrochloric acid, transfer the solid-liquid mixture of potassium dihydrogen phosphate and ammonium dihydrogen phosphate to the crystallizer, raise the temperature to 70°C, and dissolve the solid at a rate of 0.2°C / min Cool down to 15°C. The solid-liquid mixture obtained by crystallization is centrifuged, and the solid phase is put into a vacuum drying oven to dry at 70° C. to obtain potassium dihydrogen phos...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com