High-strength high-wear-resistance valve plate and preparation method thereof

A high-wear, high-strength technology, used in earthmovers/shovels, construction, etc., can solve problems such as insufficient hardness and strength, poor plastic deformation resistance, and copper adhesion, and achieve premature wear and tear. Effects of burns, good strength and abrasion resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

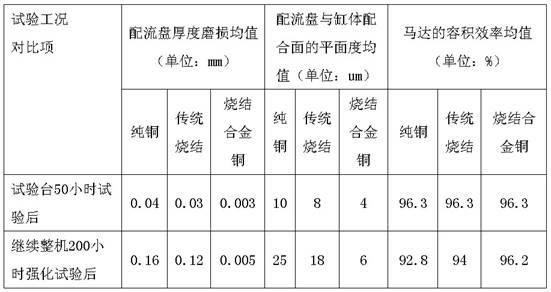

Examples

Embodiment 1

[0015] A high-strength and high-wear-resistant distribution plate, including an iron substrate, on which an electroplated copper layer and a copper alloy sintered layer are sequentially formed, and the copper alloy sintered layer is made of the following raw materials in weight percentage: Zn 0.135%, Pb 14%, Sn 6%, Fe 0.5%, Si 0.26%, Se 0.085%, P 0.008%, Ag 0.00365%, Cr 0.005%, S 0.06%, As 0.15%, Bi 0.035%, Al 0.003 %, Au 0.0045%, Zr 0.010%, B 0.0002%, C 0.085%, Nb 0.0008%, Ti 0.007%, Mn 1ppm, Be 1ppm, Sb 2ppm, Co 1ppm, Pt 1ppm and the balance of Cu.

[0016] The preparation method is as follows: 1. Prepare the iron substrate. The purchased material is S45C iron-based steel plate or round steel for machining. Generally, it is processed into a round cake shape, and the thickness is determined according to the final thickness of the part. After processing, it is required that the flatness of the surface to be sintered should be ≤0.05mm, and the roughness (smooth finish...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com