Grinding wheel for grinding large contact surface

A contact surface and grinding wheel technology, applied in the field of parts processing, can solve the problems of reduced grinding efficiency, reduced grinding length, poor grinding surface quality, etc., to solve burns, not reduce grinding efficiency, and improve grinding surface quality effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

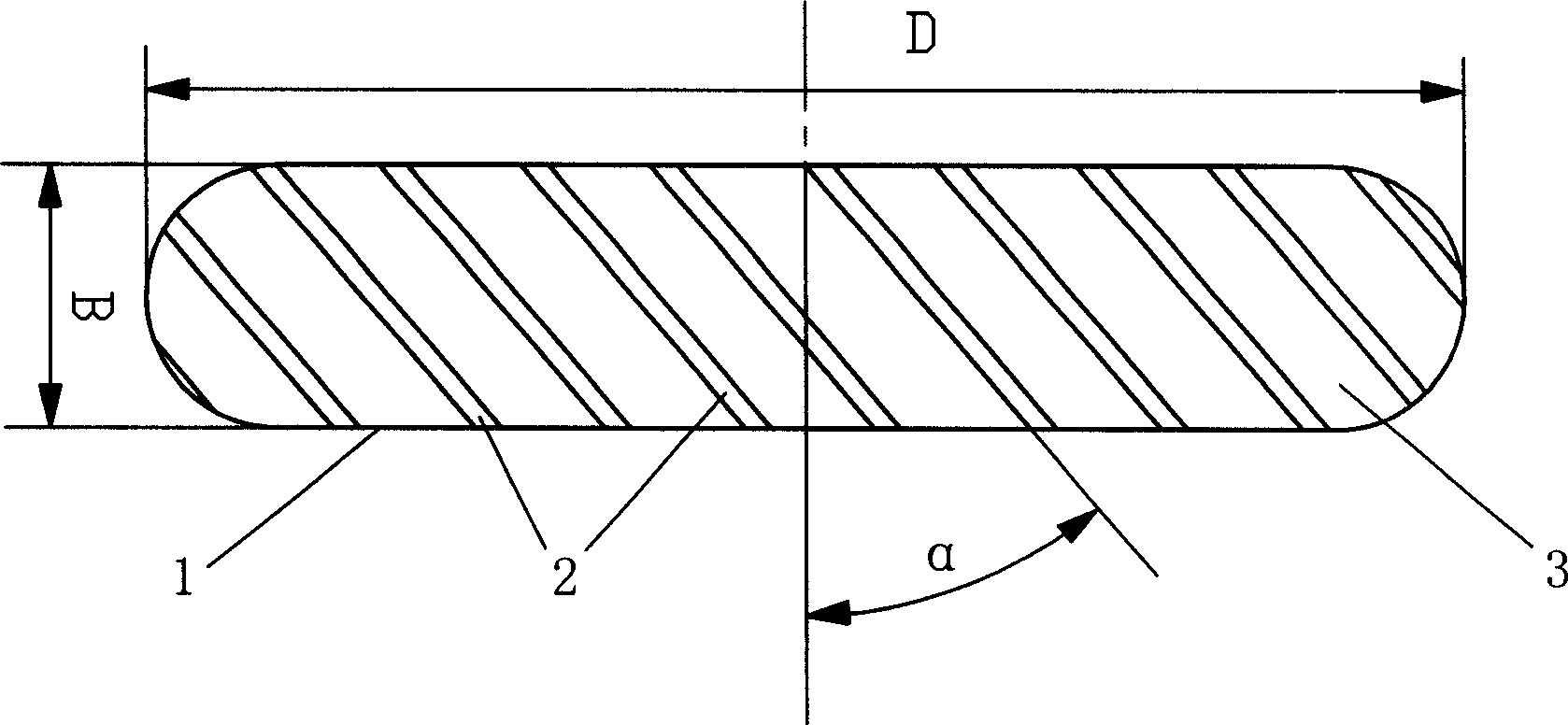

[0013] refer to figure 1 In the grinding wheel of the present invention, the grinding wheel body 1 is disc-shaped, and the outer peripheral surface 3 is the grinding surface of the grinding wheel, on which a group of chute 2 for chip removal and heat dissipation is uniformly provided. Adjacent chutes (2) partially overlap in the axial direction. The included angle (α) between the axes of the grinding wheels is 45-55°. The diameter D of the grinding wheel, the width B of the grinding wheel, the angle α between the chute and the axis of the grinding wheel, and the number N of the chute satisfy N=[arc sin(B * tgα / D)].

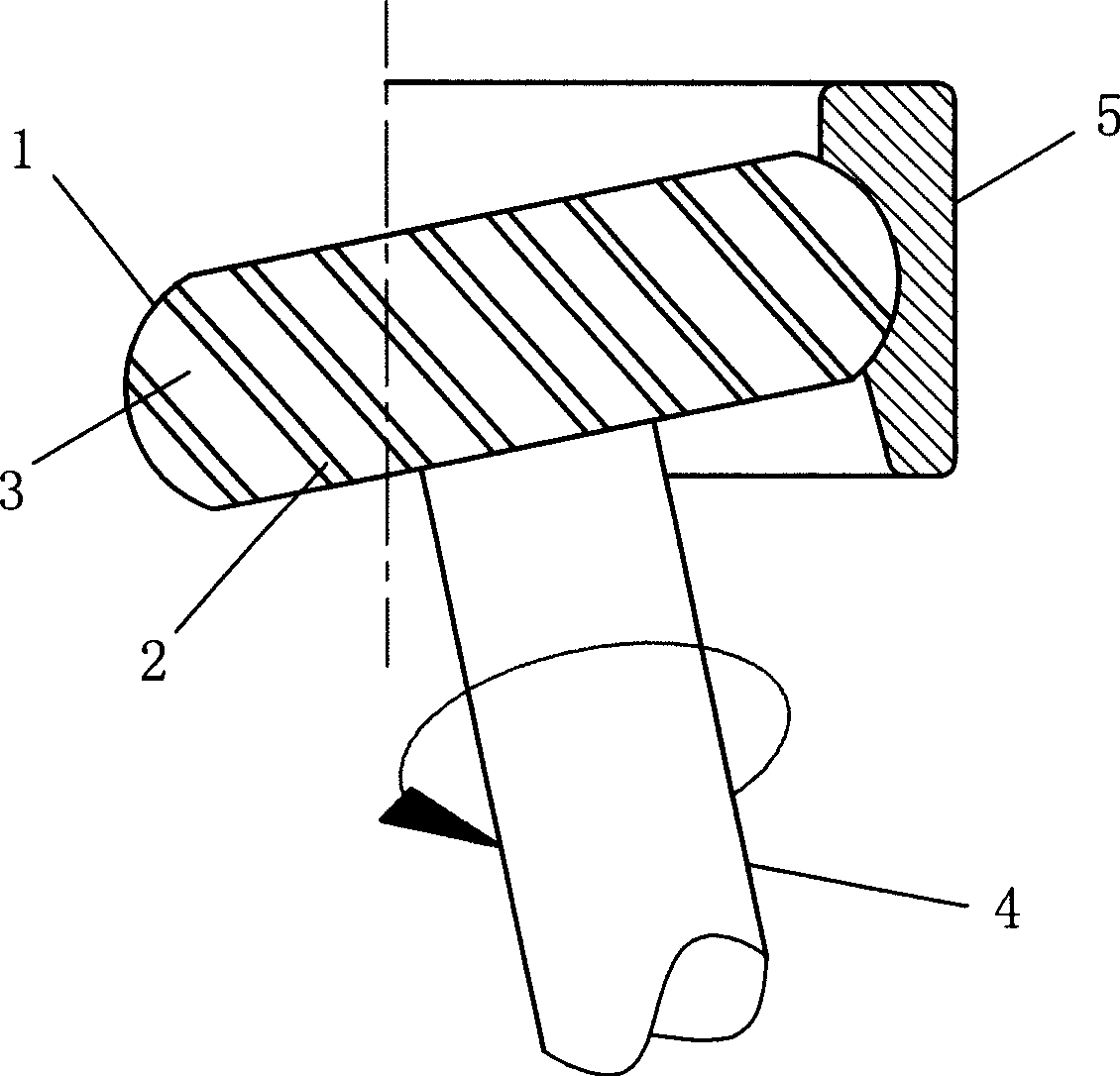

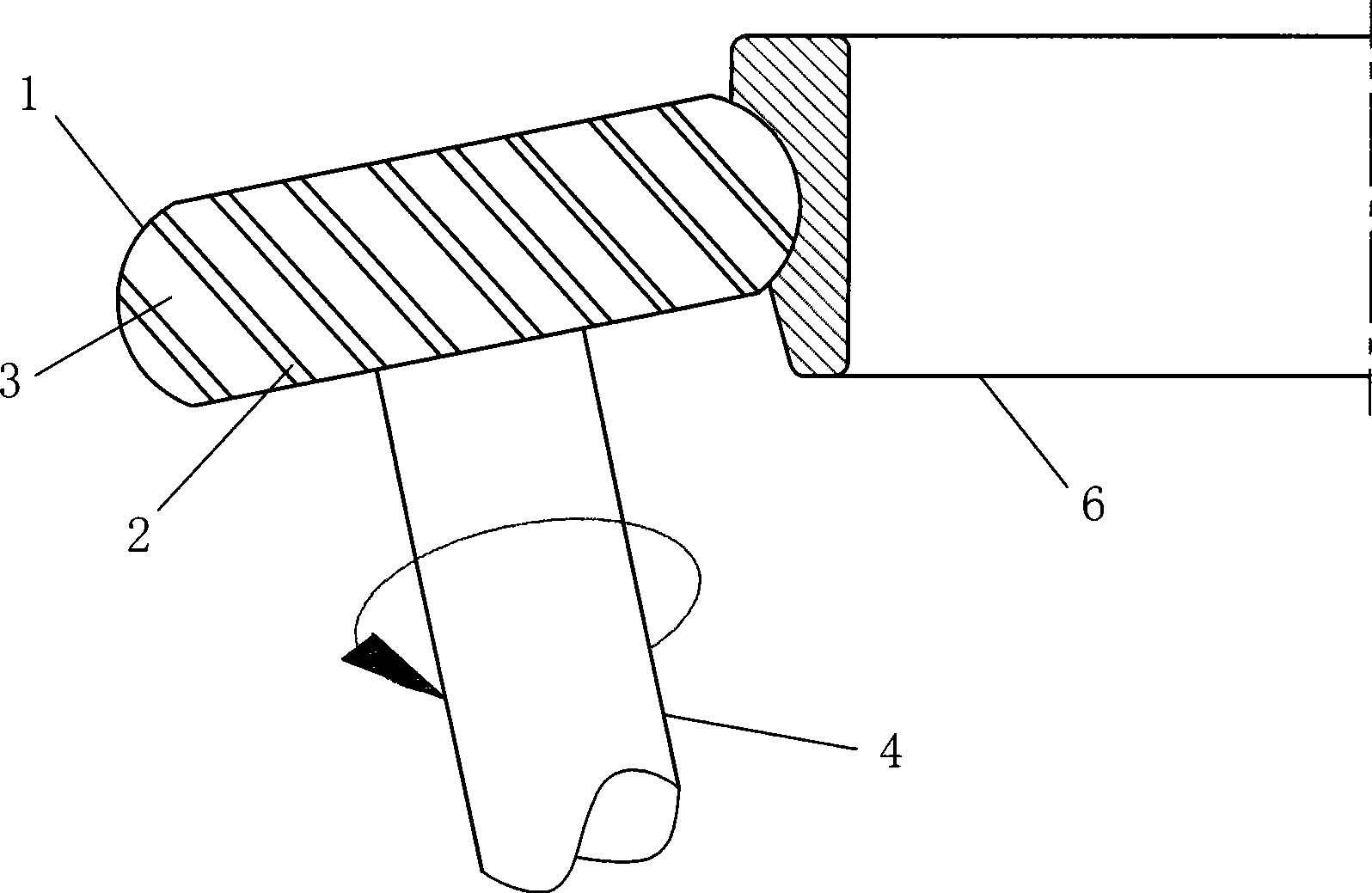

[0014] refer to figure 2 , a schematic diagram of the present invention grinding the inner groove of the bearing outer ring. The grinding wheel 1 is fixed on the shaft 4, and the shaft 4 rotates in the direction indicated by the arrow, driving the grinding wheel 1 to rotate, and the grinding surface 3 of the grinding wheel 1 forms and grinds the inner groove ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com