Novel welding and cutting dual-use device

A dual-purpose device, welding and cutting technology, applied in the direction of auxiliary devices, welding/cutting auxiliary equipment, applications, etc., can solve the problems of affecting the quality of the weld, difficult to guarantee the quality of the weld, inconvenient transportation, etc., to solve the problem of uneven incision and Excessive weld position offset, good electrical conductivity and heat dissipation, and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0021] In order to make the technical means, creative features, goals and effects achieved by the present invention easy to understand, the present invention will be further described below in conjunction with specific embodiments.

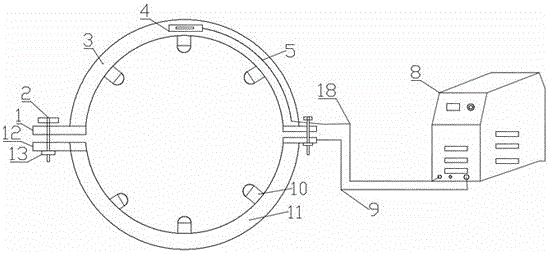

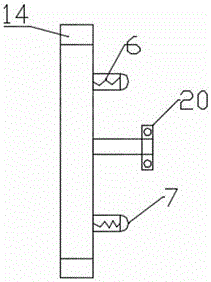

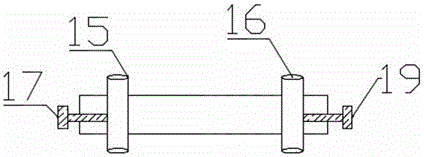

[0022] see figure 1 and figure 2 , the present invention provides a technical solution: a novel dual-purpose device for welding and cutting, including an upper snap ring 3 and a welding and cutting device 8, the model of the welding and cutting device 8 is GUT-40 plasma welding and cutting machine, because GUT-40 The plasma welding and cutting machine not only has superior performance, but also is easy to use and carry. A lower snap ring 11 is provided directly below the upper snap ring 3. At the same time, the lower snap ring 11 and the upper snap ring 3 are symmetrical up and down. On the upper snap ring 3 There are power line grooves 5 and a plurality of conductive devices 10 inside, and springs 6 and balls 7 are arranged inside the conductiv...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com