Connecting assembly of mine self-discharging vehicle front suspension frame guide mechanism and vehicle frame

A mining dump truck and guiding mechanism technology, applied in suspension, vehicle parts, transportation and packaging, etc., can solve problems such as difficulty in ensuring coaxiality, axial movement of pin shafts, complex assembly process, etc., and meet the requirements of The effect of installation coaxiality requirements, avoiding structural errors, and simple process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

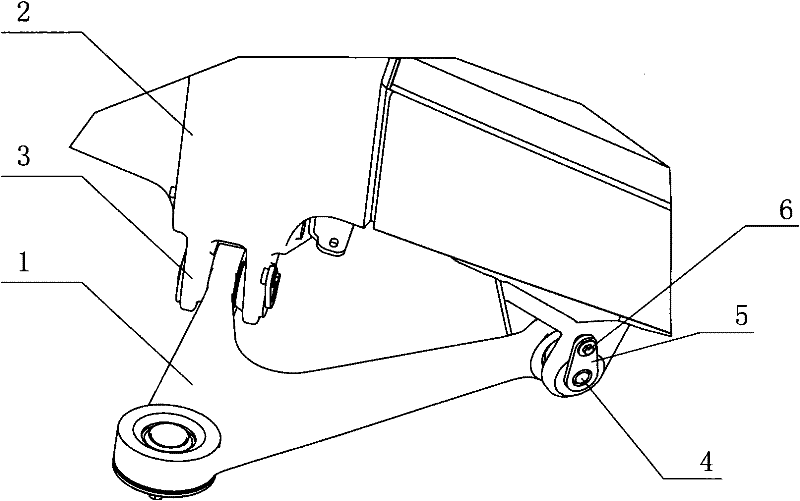

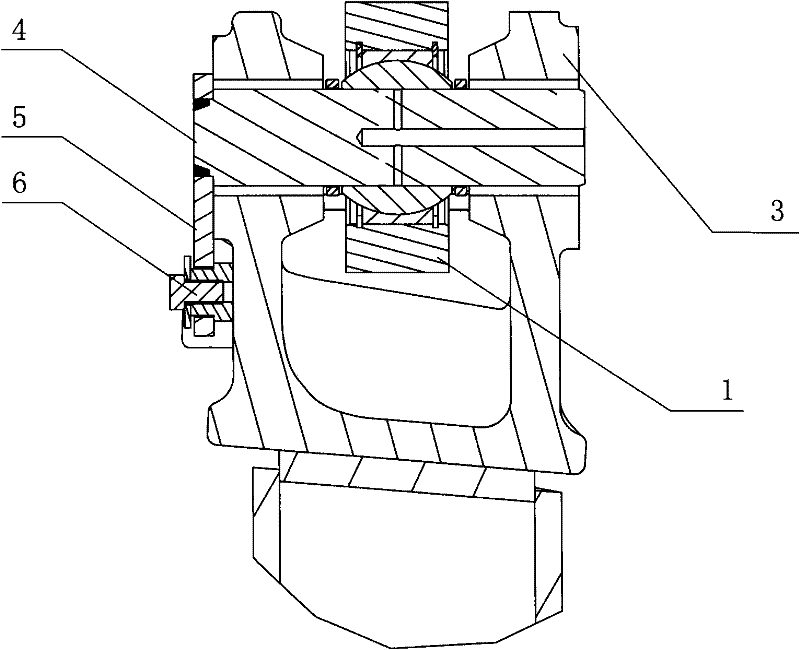

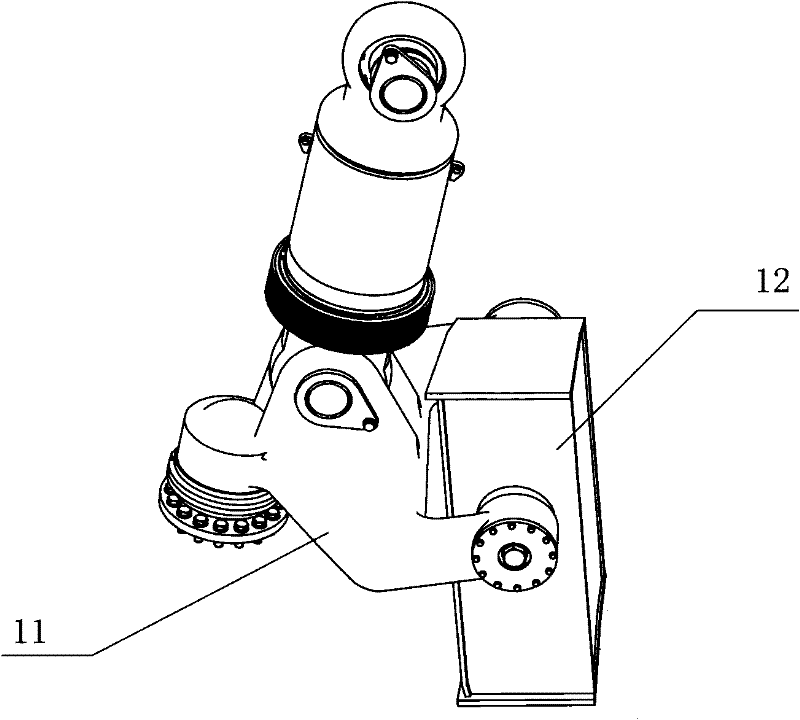

[0023] Embodiment one: see image 3 , 4 As shown, a connection assembly of a front suspension guide mechanism of a mining dump truck and a vehicle frame, the guide mechanism includes an A-arm 11, and the A-arm mounting seat 13 is provided in the vehicle frame 12, and the The two ends of the A-arm mounting seat 13 corresponding to the A-type arm 11 are respectively provided with mounting holes, and joint bearings 14 are respectively arranged in the mounting holes, and the mounting holes and the A-shaped arm mounting seat 13 are respectively connected by connecting shafts 15, One end of the connecting shaft 15 is matched with the inner ring of the joint bearing 14, and the other end of the connecting shaft 15 is provided with an eccentric boss, and an eccentric recess is formed on the inner side of the A-arm mounting seat 13 in cooperation with the eccentric boss. groove, the center of the connecting shaft 15 is provided with a screw hole, and the mounting bolt 16 is arranged i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com