Method for optimizing connection of workpiece detection flow line by aid of transfer cases which are used as carriers

A workpiece detection and optimization method technology, applied in the direction of conveyor objects, mechanical conveyors, transportation and packaging, etc., can solve the problems of low utilization rate of transmission lines, narrow equipment channels, and unsuitable cost performance, so as to improve the cost performance of the detection pipeline and reduce Equipment cost, effect of total length reduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] The present invention will be further described below in conjunction with the accompanying drawings. The following examples are only used to illustrate the technical solution of the present invention more clearly, but not to limit the protection scope of the present invention.

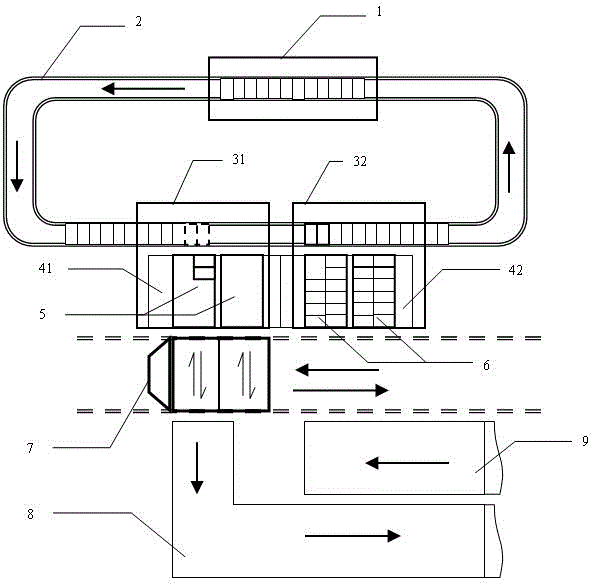

[0018] Such as figure 1 As shown, the present invention adopts a method for optimizing the connection of the workpiece detection assembly line: the shuttle car 7 is used as the connection device between the turnover box conveyors 8, 9 and the tooling pallet conveyor 2, so that the shuttle car 7 is connected between the two Carry out the ferry of the turnover box.

[0019] The turnover box conveyor includes a turnover box delivery conveyor 9 and a turnover box return conveyor 8 . The turnover box delivery conveyor 9 is used to transport the loading turnover box 6 containing workpieces to be detected from the warehouse, and the turnover box back-to-warehouse conveyor 8 is used to transport empty...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com