Filter press

A technology of filter press and filter plate, which is applied in the field of filter press, and can solve difficult problems such as large-scale and multi-chamber filter press

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

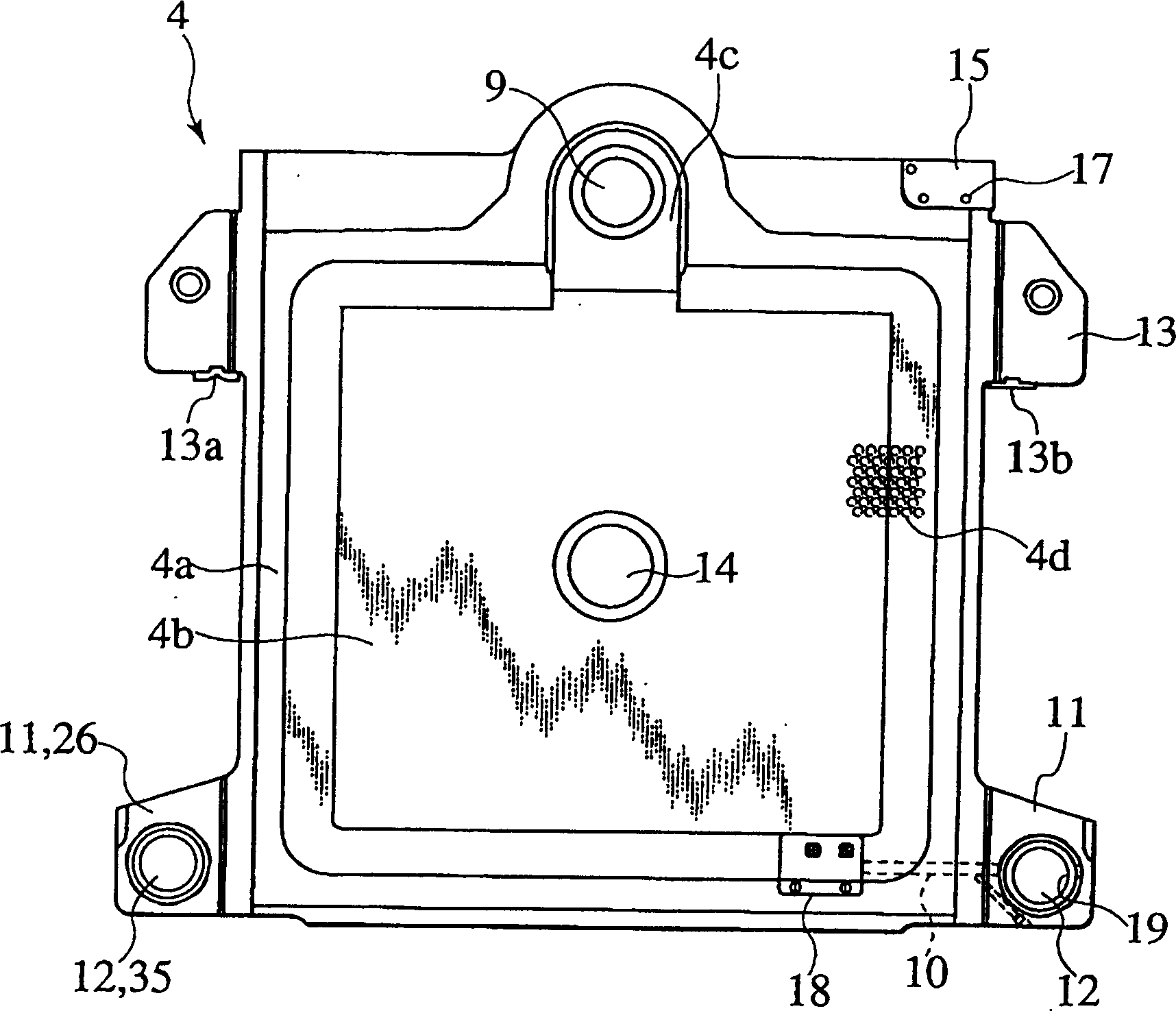

[0044] Embodiments of the present invention will be described in detail below using the drawings.

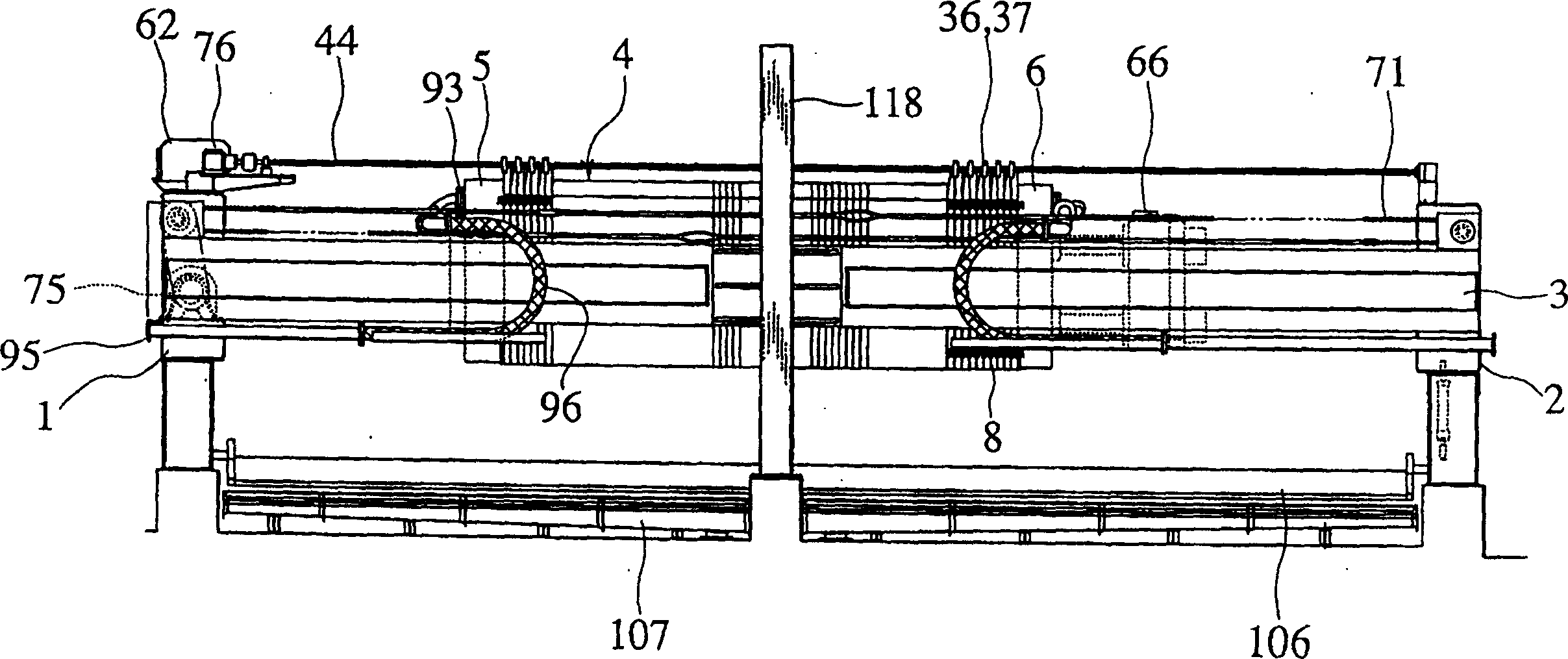

[0045] like figure 1 As shown, many side-by-side filter plates 4 are supported on a pair of parallel steel rails 3 bridged on the front frame 1 and the rear frame 2 . The front end and the rear end of the steel rail 3 are fixed on the sides of the front support 1 and the rear support 2 respectively, and the middle part is supported on the middle steel rail frame 118 .

[0046] The front movable head 5 is arranged in front of the frontmost filter plate 4 , and the rear movable head 6 is arranged behind the rearmost filter plate 4 .

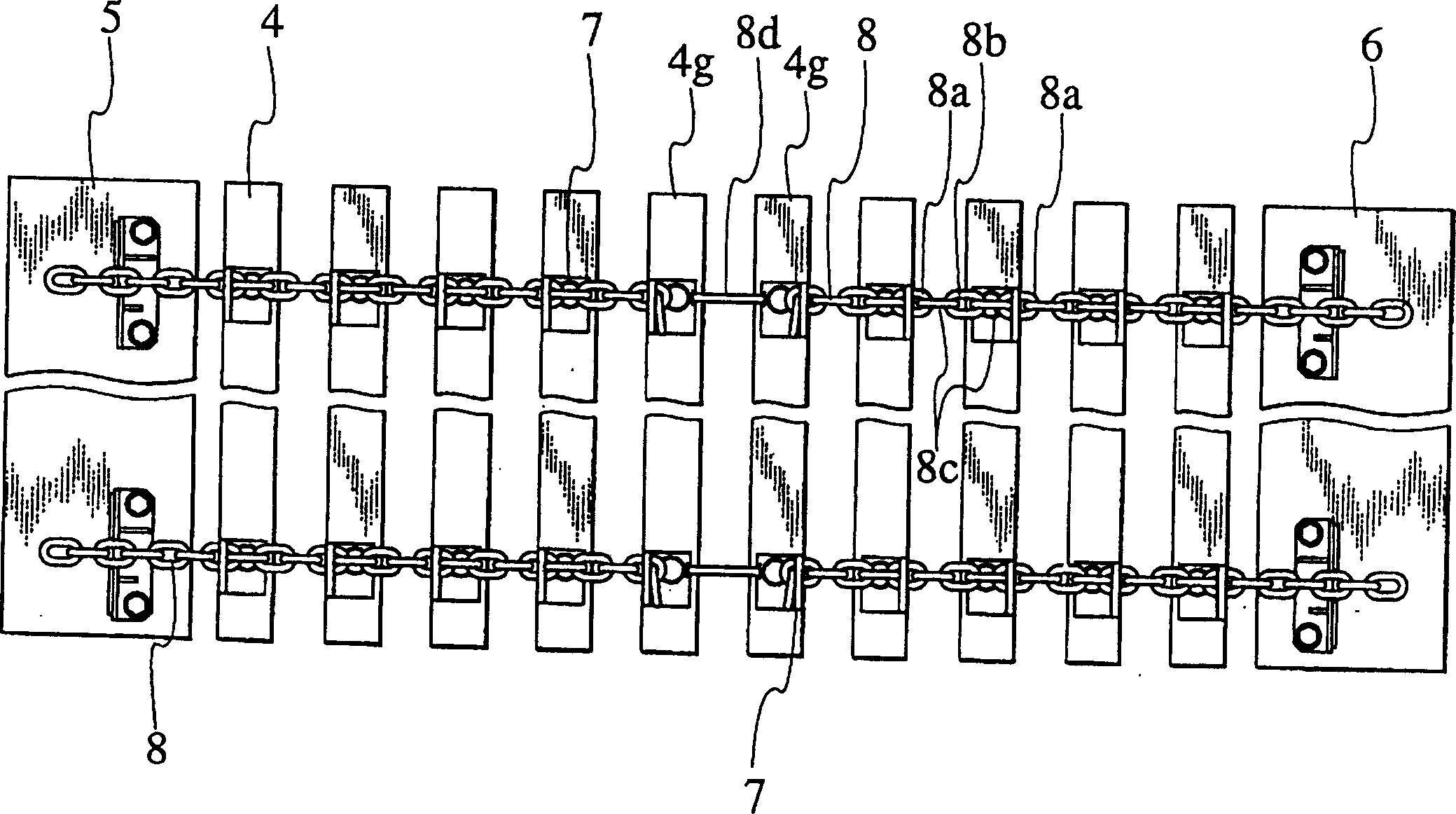

[0047] like figure 2 As shown, the filter plate 4 juxtaposed on the rail 3, the movable head 5 at the front and the movable head 6 at the rear are fixed on the locking parts 7 arranged in the upper and lower parts of the respective side walls. The endless chains, ie the moving chains 8, are connected to one another. In order to keep the interval...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com