Heat pump system, gas suction overheating degree control method, and gas-liquid separator accumulated-liquid evaporation control method

A technology of suction superheat and gas-liquid separator, applied in refrigerators, refrigeration components, refrigeration and liquefaction, etc., can solve the adverse effects of compressor operation performance, reduce refrigerant reheat superheat and compressor discharge temperature High-level problems, to avoid frosting, reduce the probability of occurrence, and reduce system costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

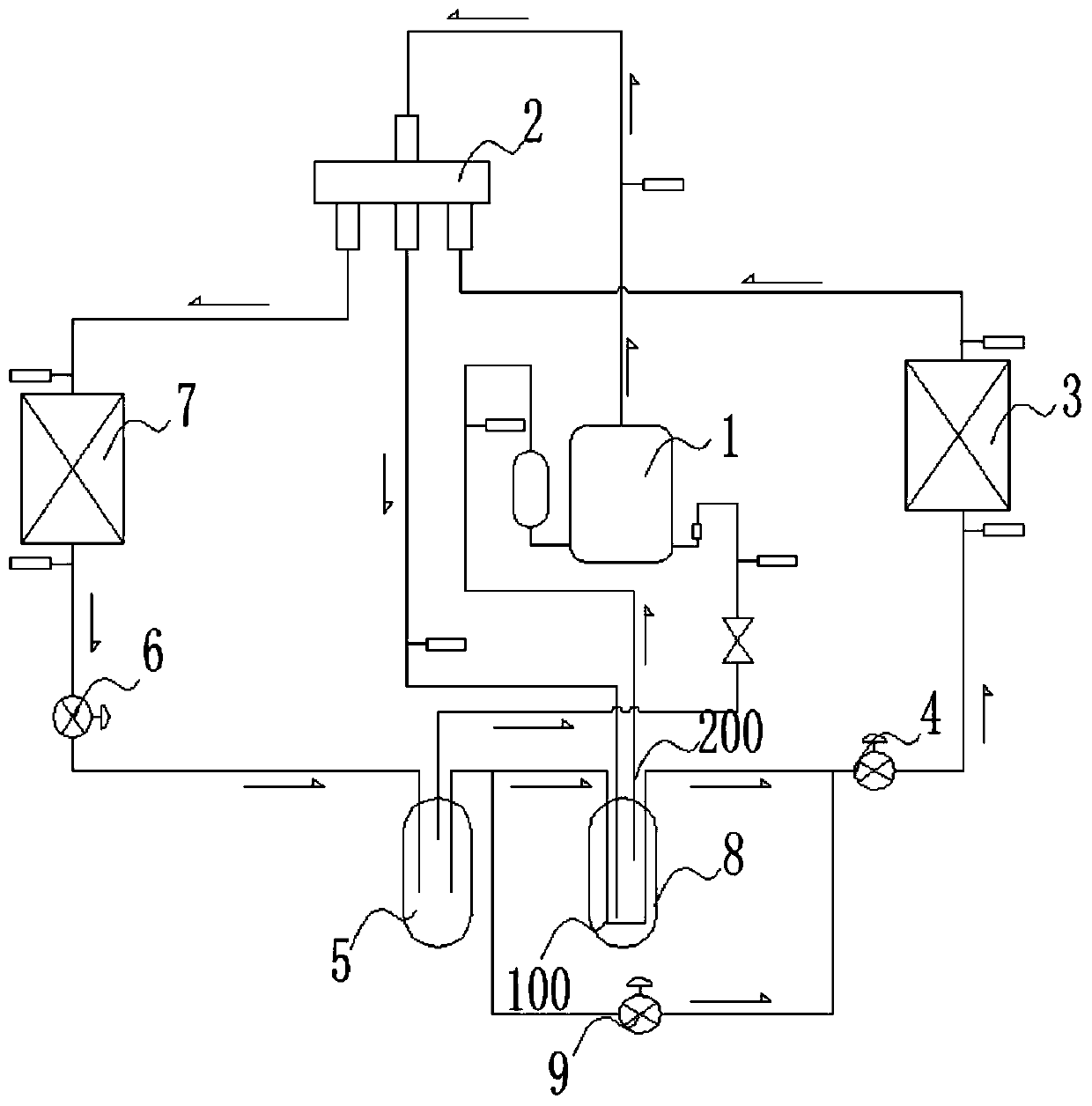

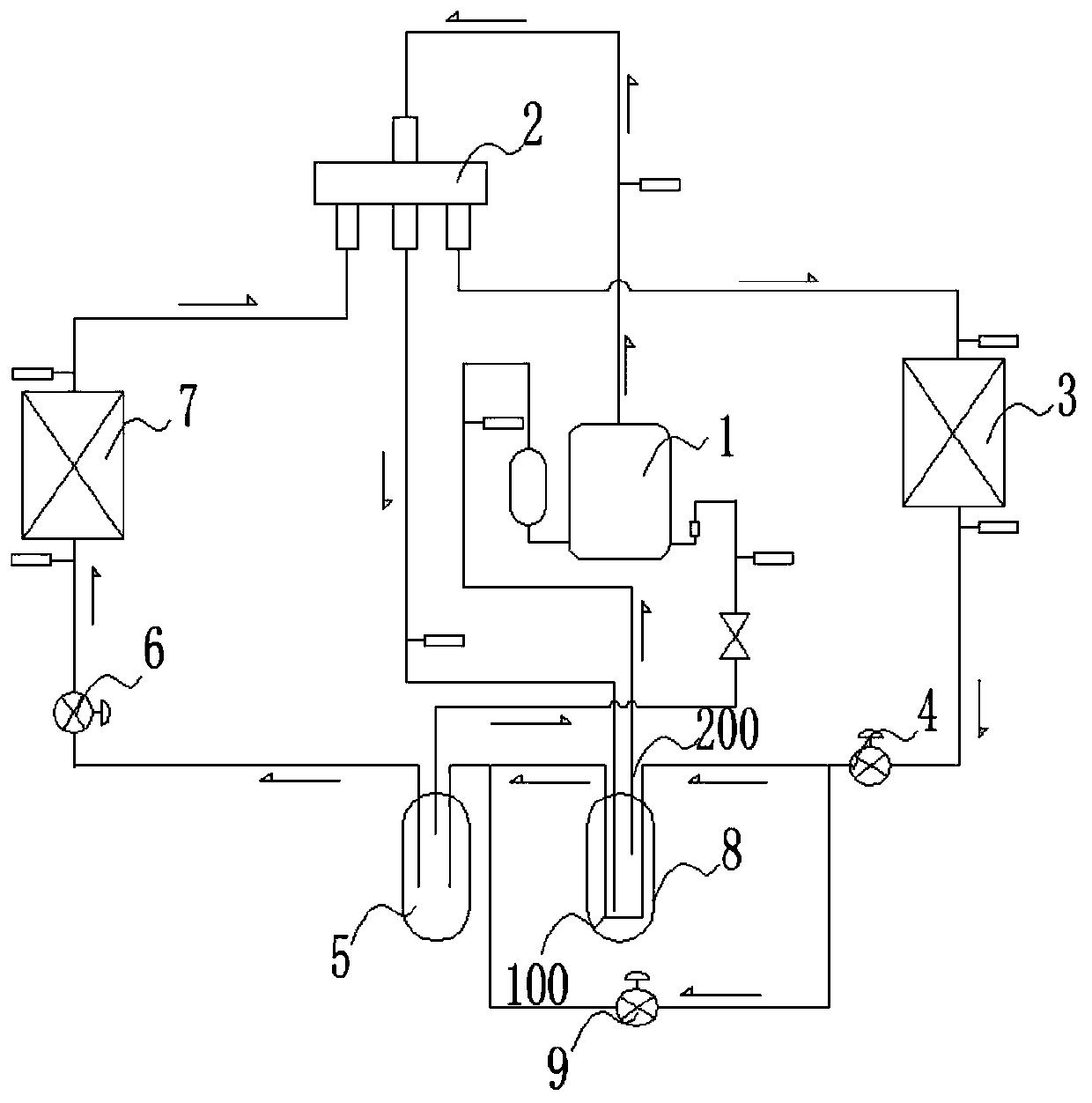

[0032] see in conjunction figure 1 , figure 2 As shown, according to an embodiment of the present invention, a heat pump system is provided, including a compressor 1, a reversing element 2, an outdoor heat exchanger 3, a first throttling element 4, a flasher 5, a second throttling element 6, Indoor heat exchanger 7, gas-liquid separator 8, the compressor 1, reversing element 2, outdoor heat exchanger 3, first throttling element 4, flash evaporator 5, second throttling element 6, indoor heat exchange The gas-liquid separator 7 and the gas-liquid separator 8 are connected by pipelines to form an air-conditioning cycle for supplementing air and increasing enthalpy, and the first pipeline 100 between the first throttling element 4 and the flash evaporator 5 is located in the gas-liquid separator 8 , so as to transfer the heat of the refrigerant in the first pipeline 100 to the gas outlet pipe 200 of the gas-liquid separator 8 . With this technical solution, on the one hand, the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com