Control method for reducing oil-jetting apparatus of rotary compressor and uses thereof

A technology of a rotary compressor and a control method, which is applied to components of pumping devices for elastic fluids, rotary piston type/oscillating piston type pump components, rotary piston type pumps, etc., and can solve the problem of reducing oil discharge from compressors The structure is complicated to make, and it is not universal

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 example

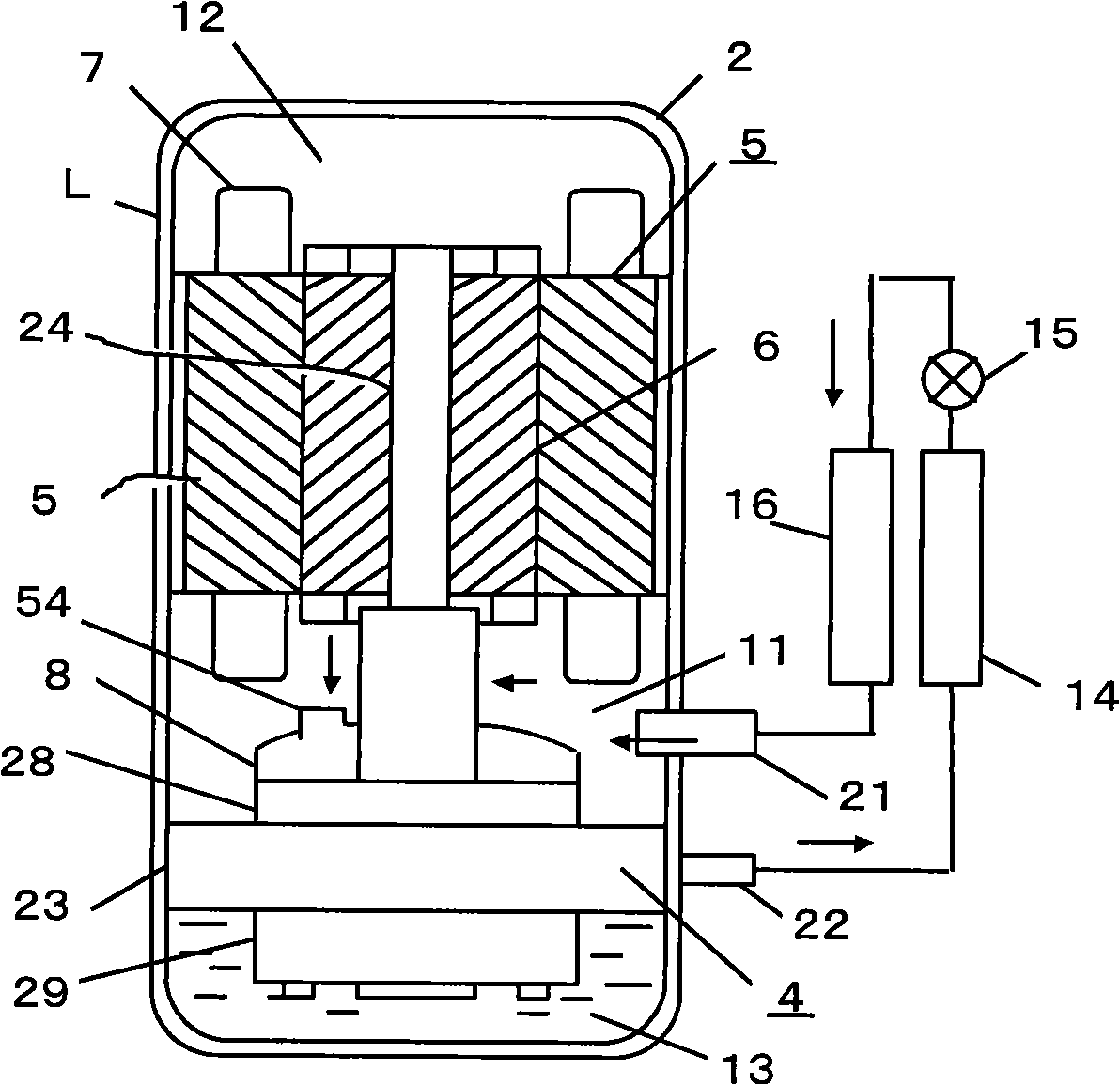

[0027] The following is based on figure 1 The form of the first embodiment of the present invention will be described. figure 1 The schematic structure of the rotary compressor of this invention and an example of the structure of the system equipped with this compressor are shown. The system can be air conditioner, refrigeration equipment and water heater etc. The internal pressure of the shell of the rotary compressor used in the first embodiment is the same as that of the suction, and both are on the low pressure side, so this compressor can be called a rotary compressor L with low shell back pressure.

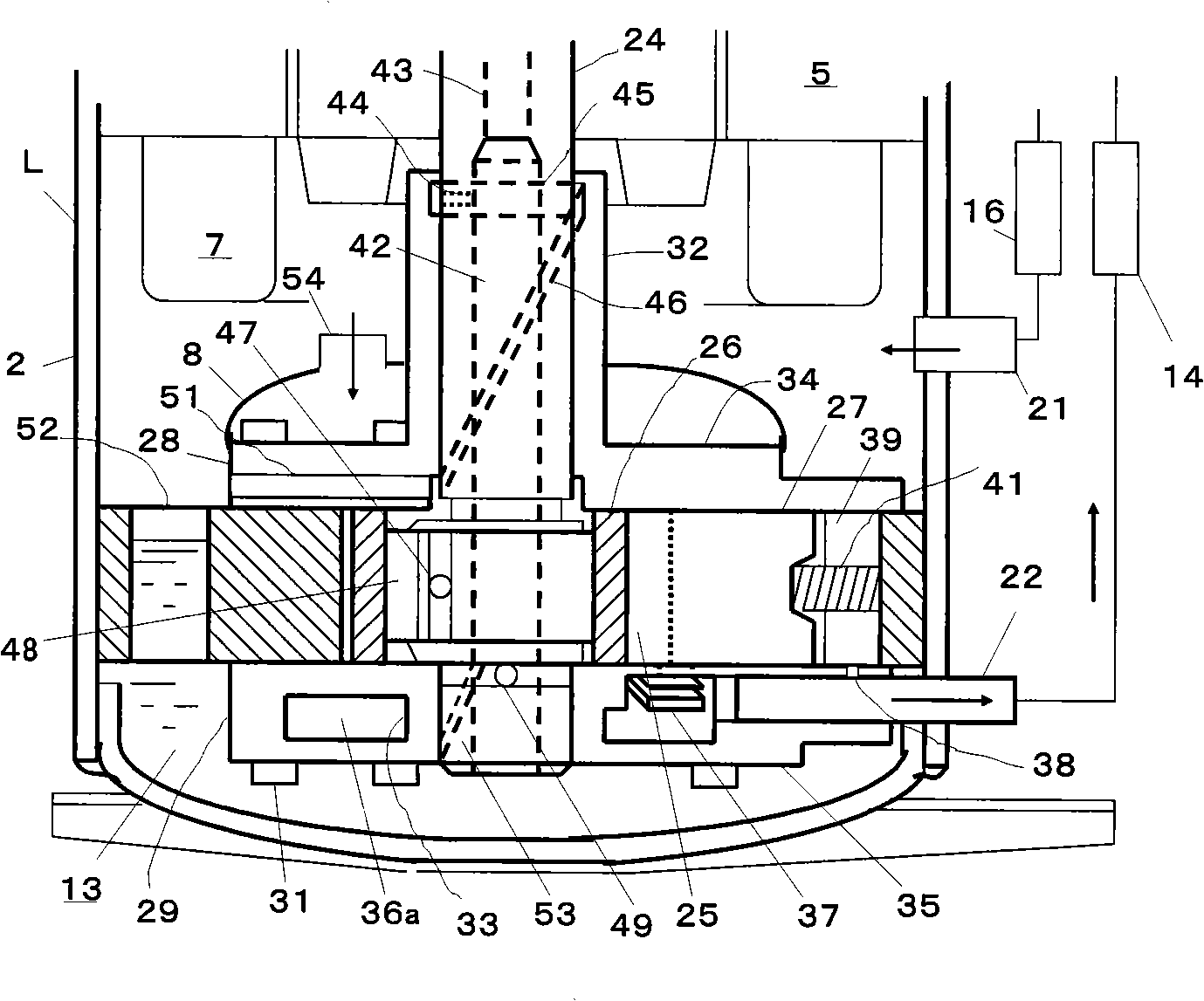

[0028] A motor 3 is arranged in the sealed casing 2 of the rotary compressor L with low casing back pressure, and a compression assembly 4 of the compressor is arranged below it, and they are fixed inside the casing 2 . The motor 3 consists of a stator 5 with motor windings and a rotor 6 . There is a suction muffler 8 at the top of the compression assembly 4 of the compre...

no. 2 example

[0043] In the second embodiment of the present invention, the internal pressure of the casing of the rotary compressor is the same as the discharge of the compressor, which is on the high pressure side. This compressor may be referred to as a shell high pressure rotary compressor H. The difference between the second embodiment of the present invention and the first embodiment will be mainly described below.

[0044] see Figure 5-Figure 6 , In the high-pressure rotary compressor H of the shell, the side of the compression assembly 4 has a suction pipe 21, the base of the main bearing is provided with an exhaust muffler H 36b, and the upper end of the shell 2 has an exhaust pipe 22. Next, the internal structure of the compressor and the gas flow direction of the system will be described. From the evaporator 16 through the suction pipe 21, the low-pressure gas directly sucked by the cylinder compression chamber 25 is compressed and becomes a high-pressure gas, which is dischar...

no. 3 example

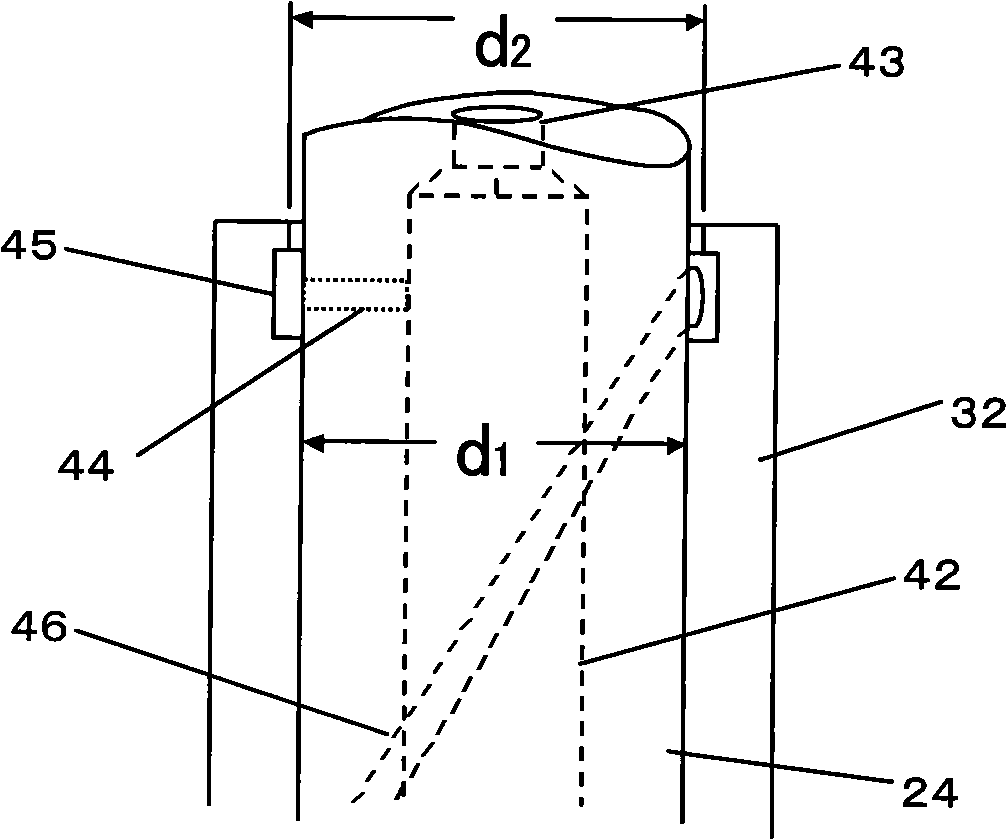

[0053] see Figure 7 , the sleeve pipe 62 is pressed into the vertical hole 43 on the crankshaft. According to this design, it can prevent the oil in the lower vertical hole 42 of the crankshaft from flowing out from the upper end of the crankshaft 24 to the inside of the housing through the upper vertical hole 43 during operation, and can further improve the oil supply effect to the first horizontal hole 44 .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com