Percussion hammer and/or drill hammer comprising a safety coupling

A technology of impact hammer and impact drill, applied in the direction of light impact tools, impact tools, wrench, etc., can solve the problems of unfavorable equipment control, etc., and achieve the effect of easy pre-assembly

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

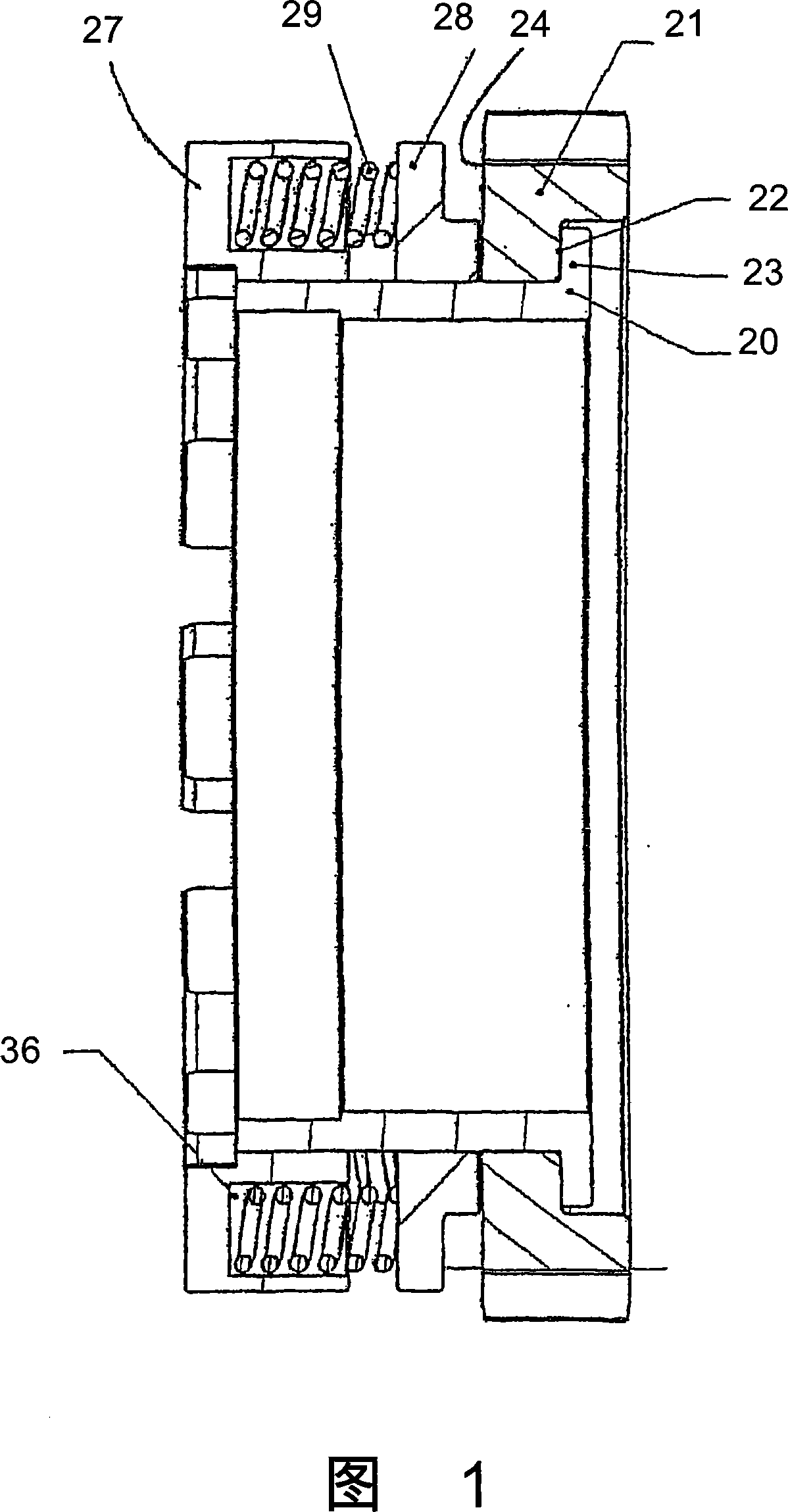

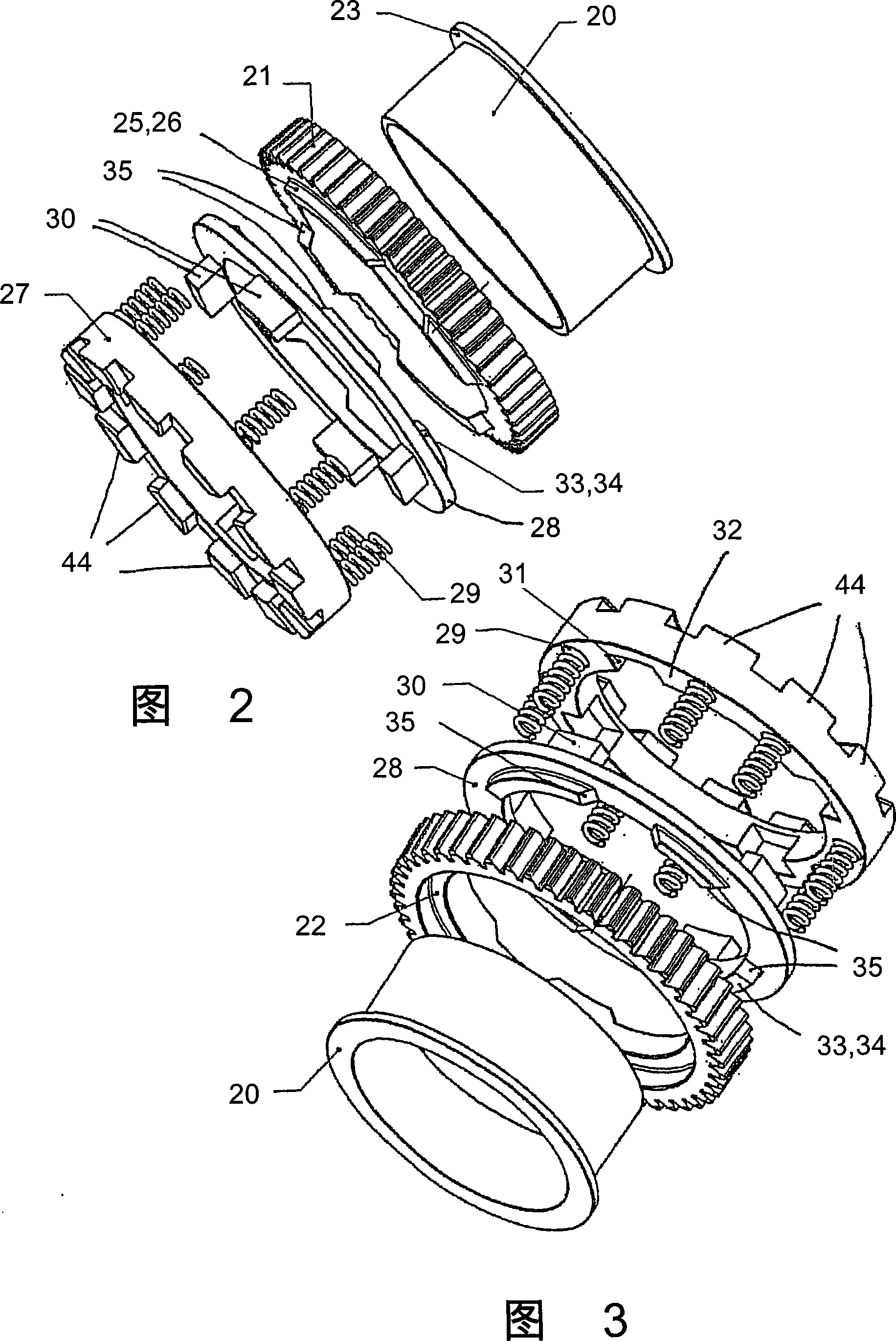

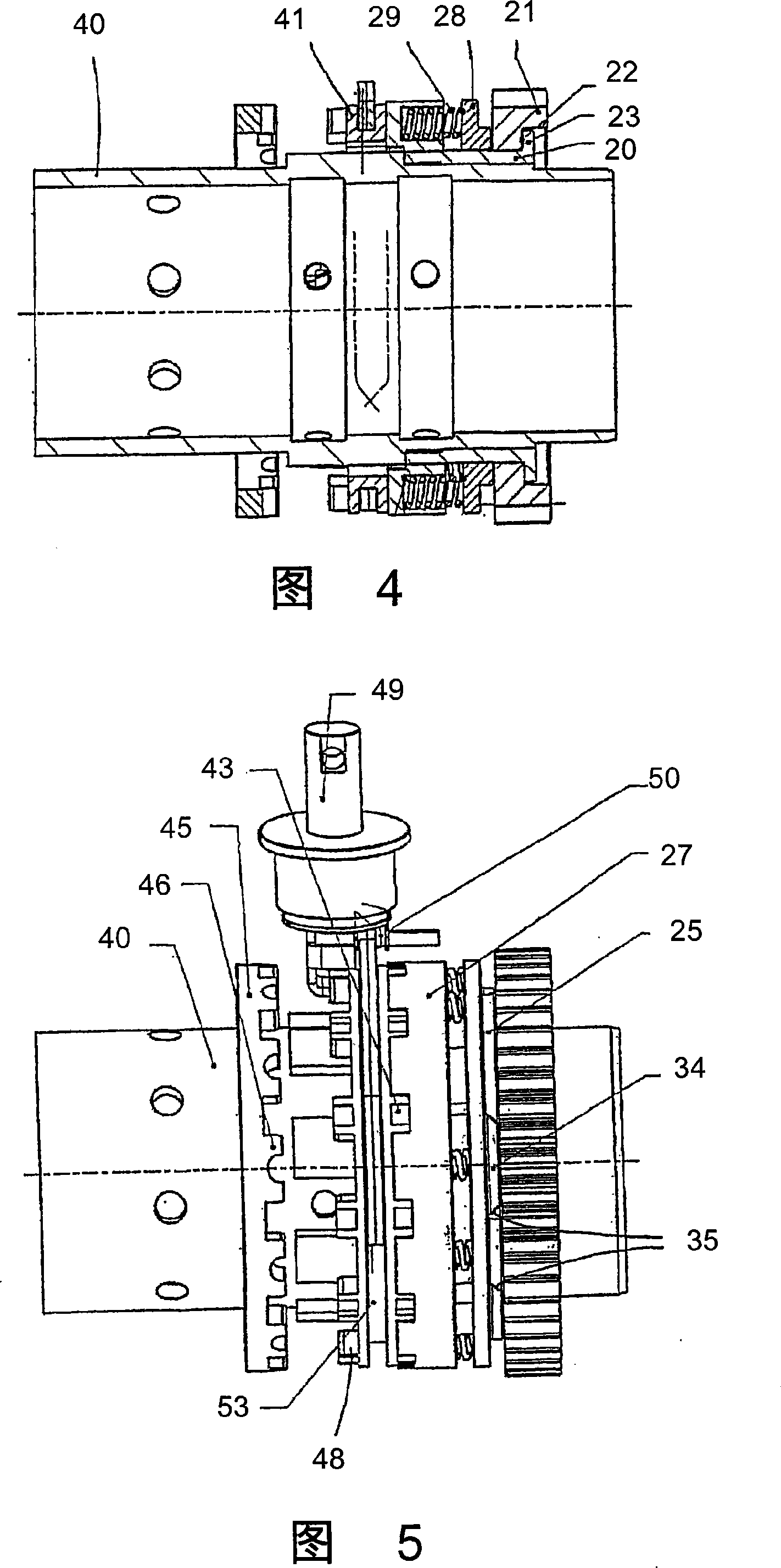

[0040] A transmission gear 21 is installed on the standard socket 20 , and its smooth sliding surface 22 pushes against the flange ring 23 on the standard socket 20 . The transfer gear 21 is free to rotate relative to the standard socket 20 and meshes with a mating gear (not shown in the figure) from which the transmission torque (of the drive device not shown in the figure) is transmitted. On the side of the end surface 24 opposite the smooth sliding surface 22 of the transmission gear 21, there is a ratchet meshing surface 26 composed of a plurality of radially staggered pawls 25 (see accompanying drawing 2)

[0041] On the end of the standard nipple 20 opposite the flange ring 23 is mounted an adapter ring 27 (eg press-fitted). Of course, other ways can also be used to fix the adapter ring 27 on the standard socket 20, such as fixing with screws, or forming an integral body with it.

[0042] An axially movable locking ring 28 is installed between the engaging ring 27 and t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com