High-temperature-resistant and rainfall-erosion-resistant wave transmission antenna housing and preparation method thereof

A technology of high temperature resistance and radome, applied in the field of radome, can solve the problems of rain erosion of the radome, increase the number of flying times of the radome, and achieve the effect of overcoming temperature resistance, less defects, and excellent high temperature resistance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

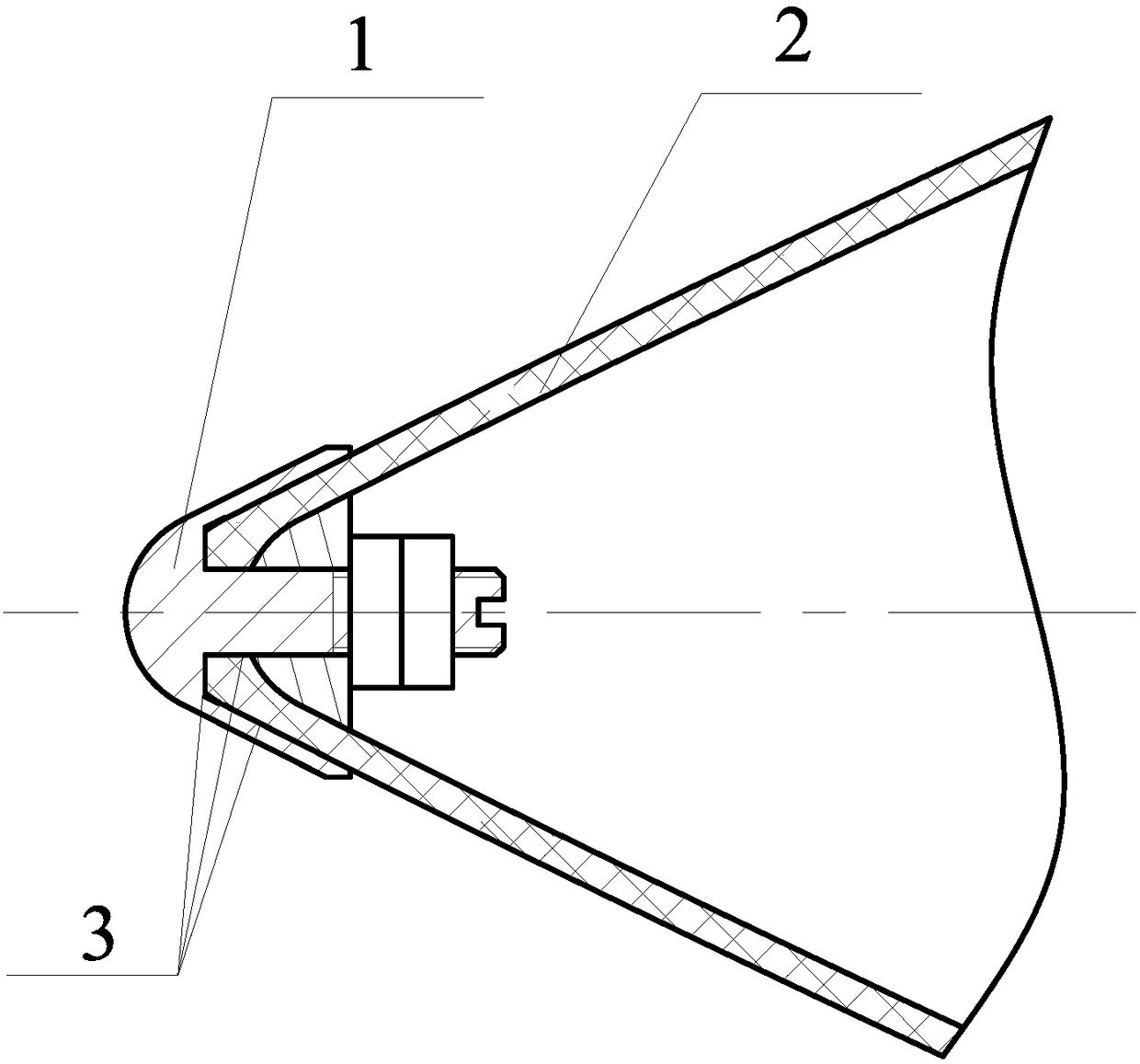

[0040] 1. Prepare the radome cover body and rain erosion head

[0041]1) The radome cover body is made of polyarylene resin / quartz fiber composite material, cut 20 layers of 0.2mm quartz fiber cloth according to the positive model surface of the radome cover body, and weigh the resin according to the mass ratio of resin:quartz fiber cloth 40:60, Then use a squeegee to evenly scrape the resin onto the quartz fiber cloth, close the mold after fully wetting, and cure according to the curing process of 120°C / 4h, 160°C / 4h, 200°C / 4h, 250°C / 4h, and wait for the mold After natural cooling to room temperature, the radome body is released from the mold, and then the radome body is machined to the specified height, and the radome body head is machined to the specified size.

[0042] 2) Rain erosion head processing

[0043] The rain erosion head is made of aluminum alloy and machined to the specified size.

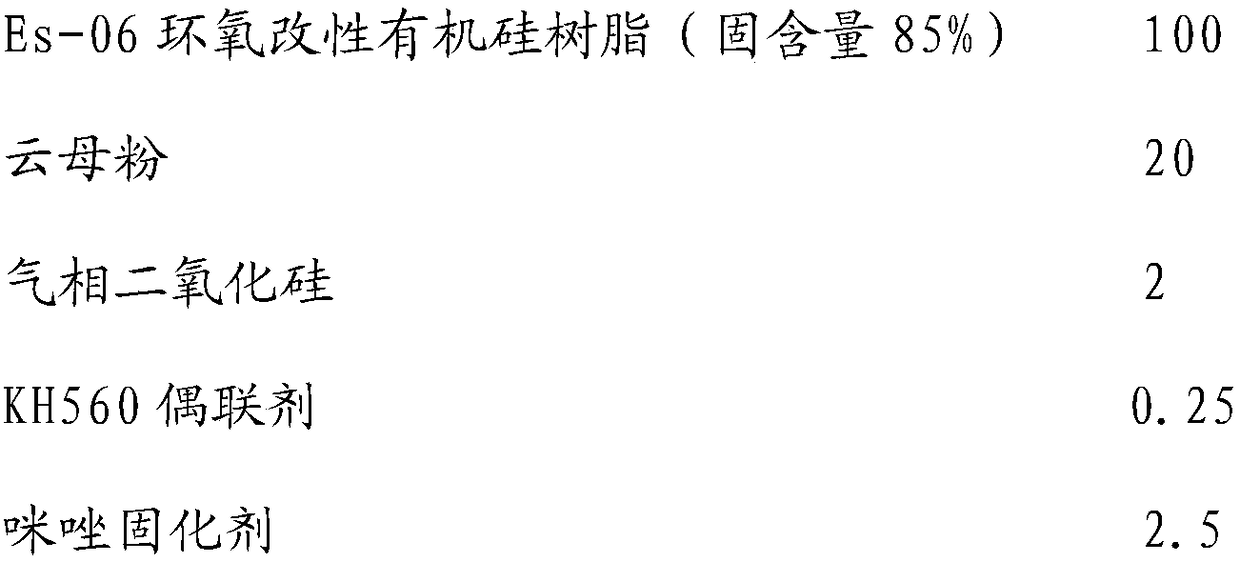

[0044] 2. Preparation of high temperature resistant wave-transparent adhesive ...

Embodiment 2

[0054] 1. Prepare the radome cover body and rain erosion head

[0055] 1) The radome cover body is made of polyarylene resin / quartz fiber composite material, and 20 layers of 0.2mm quartz fiber cloth are cut according to the positive model surface of the radome cover body, and the resin is weighed according to the mass ratio of resin:quartz fiber cloth of 30:70, Then use a squeegee to evenly scrape the resin onto the quartz fiber cloth, close the mold after fully wetting, and cure according to the curing process of 120°C / 4h, 160°C / 4h, 200°C / 4h, 250°C / 4h, and wait for the mold After natural cooling to room temperature, the radome body is released from the mold, and then the radome body is machined to the specified height, and the radome body head is machined to the specified size.

[0056] 2) Rain erosion head processing

[0057] Rain erosion heads are constructed of stainless steel and machined to size.

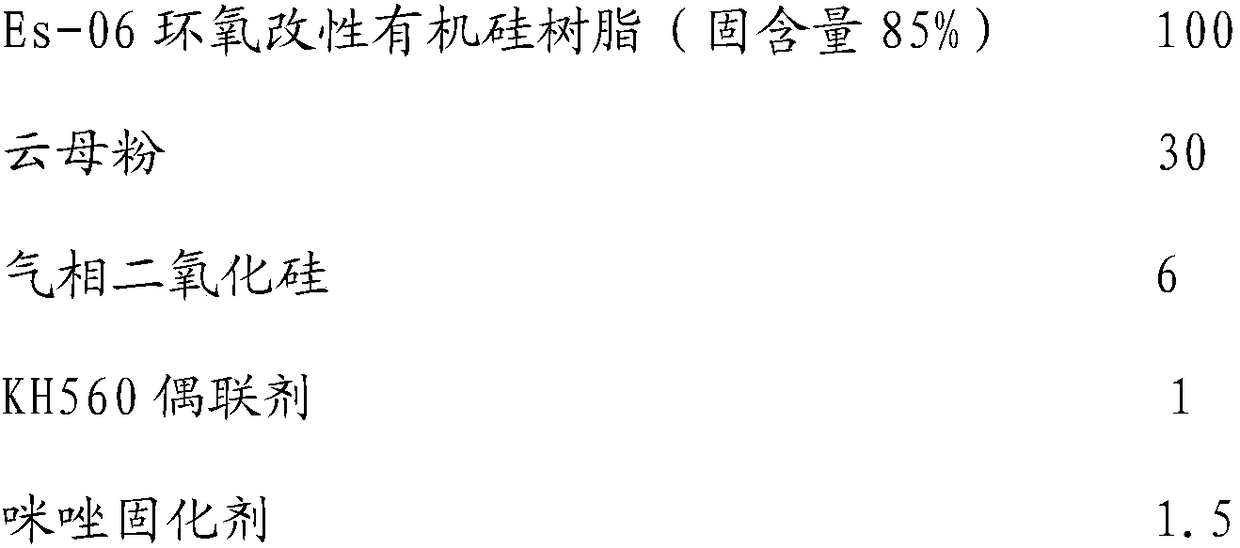

[0058] 2. Preparation of high temperature resistant wave-transparent a...

Embodiment 3

[0067] 1. Prepare the radome cover body and rain erosion head

[0068] 1) The radome cover body is made of polyarylene resin / quartz fiber composite material, cut 20 layers of 0.2mm quartz fiber cloth according to the positive model surface of the radome cover body, and weigh the resin according to the mass ratio of resin:quartz fiber cloth 40:60, Then use a squeegee to evenly scrape the resin onto the quartz fiber cloth, close the mold after fully wetting, and cure according to the curing process of 120°C / 4h, 160°C / 4h, 200°C / 4h, 250°C / 4h, and wait for the mold After natural cooling to room temperature, the radome body is released from the mold, and then the radome body is machined to the specified height, and the radome body head is machined to the specified size.

[0069] 2) Rain erosion head processing

[0070] The rain erosion head is made of aluminum alloy and machined to the specified size.

[0071] 2. Preparation of high temperature resistant wave-transparent adhesive ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com