Encapsulation structure and encapsulation method for MEMS (micro-electromechanical system) variable optical attenuator

A technology of dimming attenuation and packaging structure, which is applied in the coupling of optical waveguides, etc., can solve the problems of lower yield and higher device cost, and achieve the effects of low cost, avoiding welding process, and convenient optical path adjustment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0047] The present invention will be further described below in conjunction with specific embodiment:

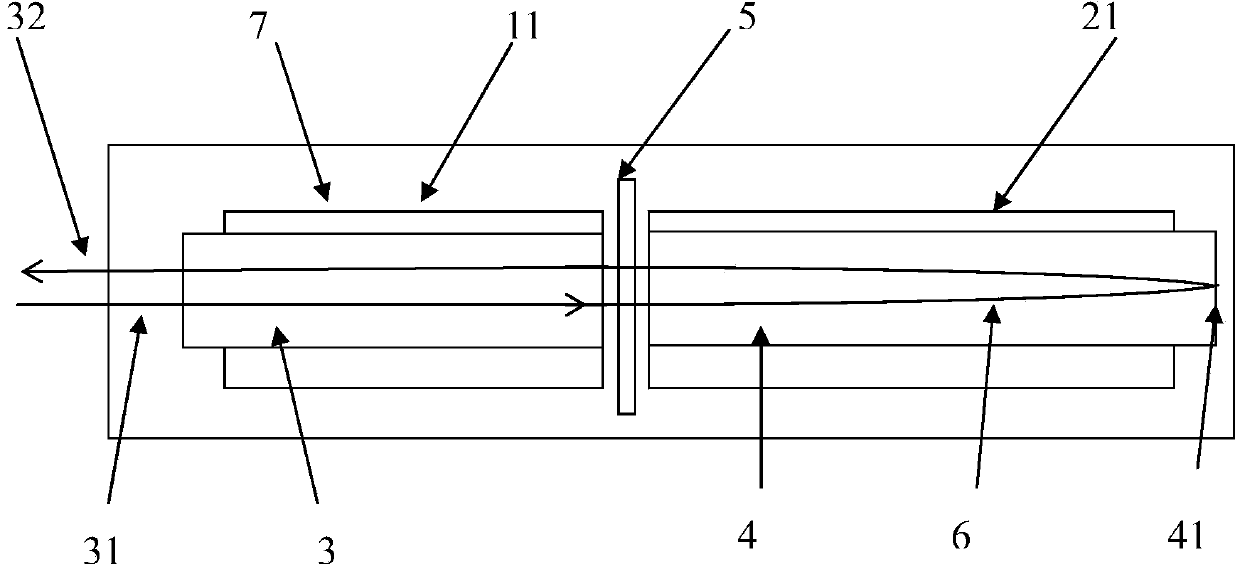

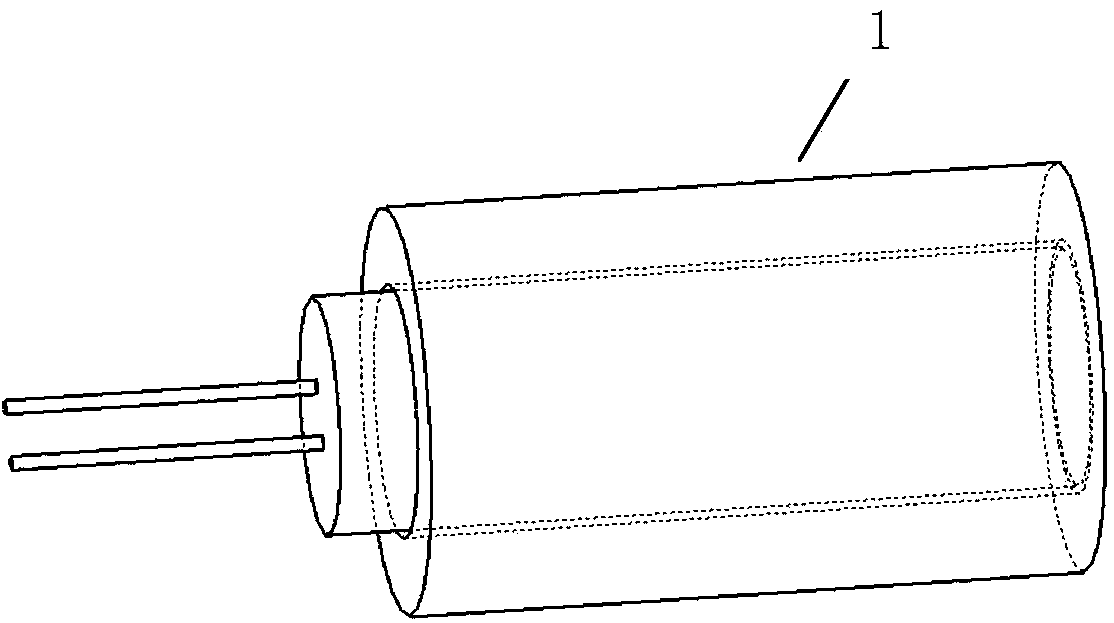

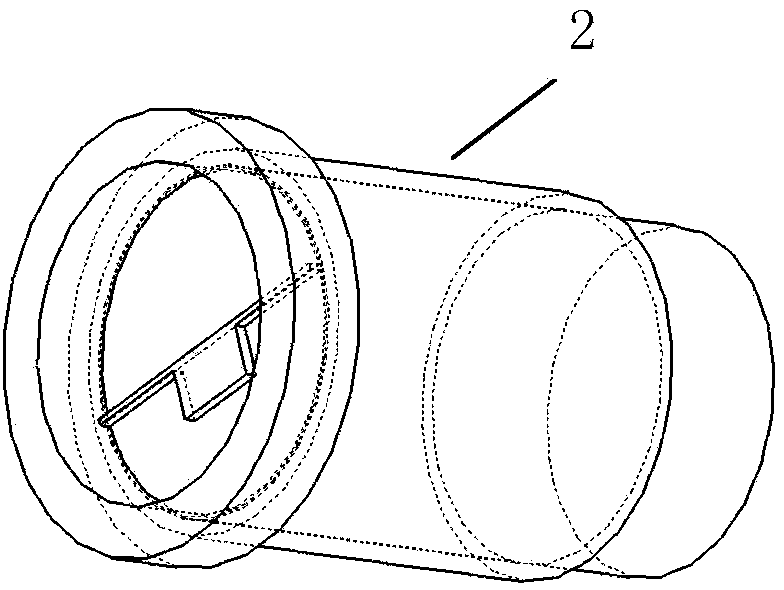

[0048] Such as figure 1 , figure 2 ,and image 3 As shown, a package structure of a MEMS tunable optical attenuator includes a focusing lens 4, a pigtail tube 3 with an input optical fiber 31 and an output optical fiber 32, and an optical chip 5 made by a micro-electromechanical system. The focusing lens is a self-focusing lens. The pigtail sleeve with input optical fiber and output optical fiber is fixed in a hollow cylindrical magnet 11 with adhesive glue to form a magnetic assembly 1; one end of the self-focusing lens is an optical signal incident surface, and the other end has a light reflection surface 41, and the light of the self-focusing lens The converging point is located on the light reflecting surface 41; the self-focusing lens is fixed in another hollow cylindrical magnet 21 with adhesive; The upper end used to attract and engage with the magnetic assembly ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com