Thermal-network parameter identification method based on IGBT junction temperature information

A parameter identification and thermal network technology, applied in the electric power field, can solve problems such as difficulty in implementation, complex mathematical transformation, and very demanding measurement conditions, so as to reduce operation and maintenance costs and ensure safe operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

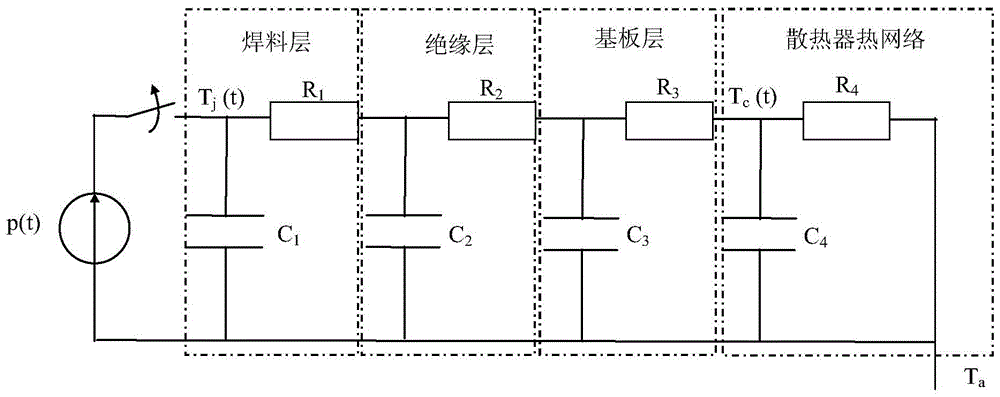

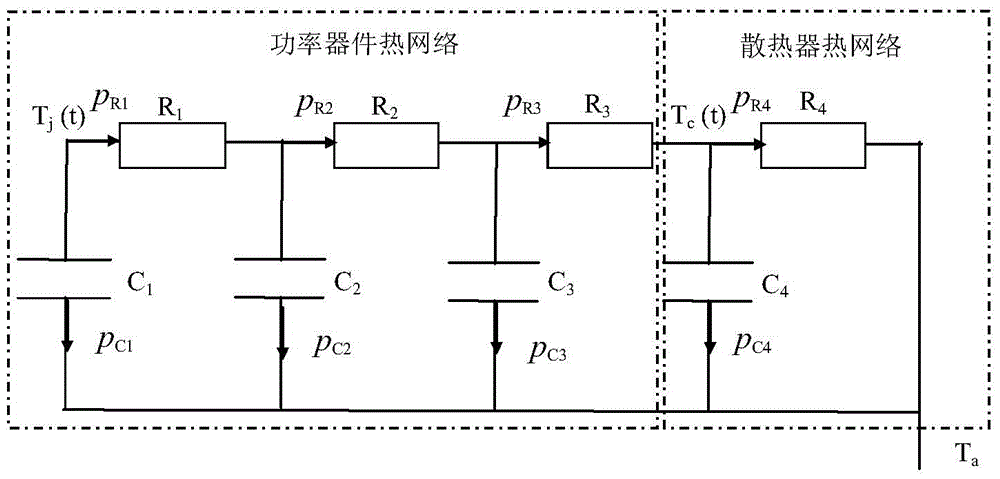

[0026] The present invention will be further described below in conjunction with accompanying drawing and embodiment: figure 1 is the Cauer type thermal network of the simplified IGBT module and radiator of the present invention, figure 2 It is the Cauer type thermal network of the IGBT module and the radiator under the equivalent zero input state of the present invention.

[0027] Such as figure 1 As shown, the thermal network parameter identification method based on IGBT junction temperature information in this embodiment is characterized in that it includes

[0028] a. According to the performance parameters of the IGBT module and the radiator, an equivalent thermal network model is established;

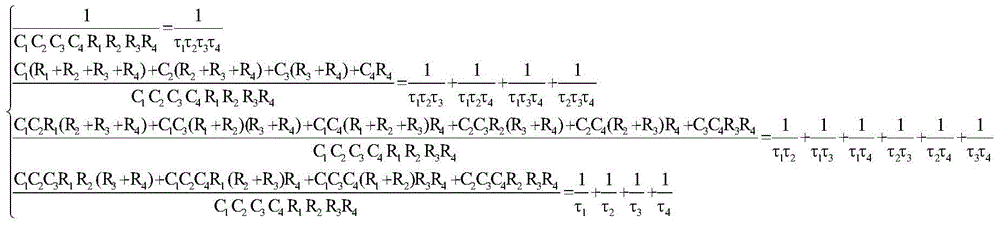

[0029] b. Establish the IGBT thermal network parameter constraint equation by changing any set of measurable equivalent thermal network model parameters in the equivalent thermal network model;

[0030] c. Measure the cooling curve before and after changing the equivalent ther...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com