Discretized square wave extraction method and apparatus for IGBT coupling thermal impedance

An extraction method and extraction device technology, applied in the field of discrete square wave extraction method and device, can solve the problems of long simulation analysis time, large thermal resistance deviation, difficulty in extracting IGBT module coupling thermal impedance, etc., and achieve accurate measurement and fast response Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

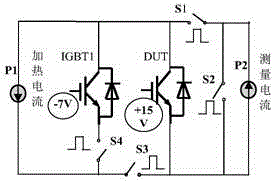

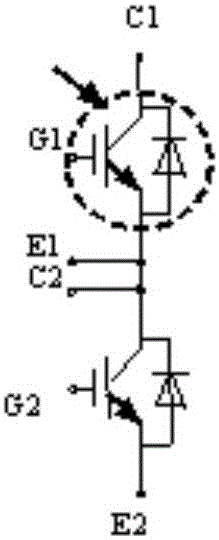

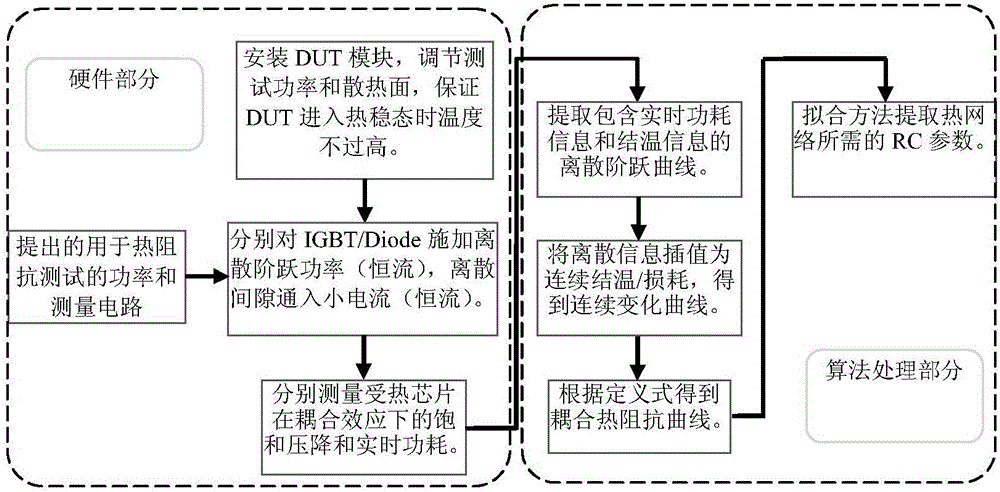

[0039] The present invention will be further described below in conjunction with accompanying drawing and embodiment: figure 1 is the equivalent circuit diagram inside the IGBT module of the present invention, figure 2 is a block diagram of coupling thermal impedance extraction in the present invention, image 3 It is a schematic diagram of the respective fitting temperature sensitivity coefficient curves of the IGBT chip and the FWD chip of the present invention, Figure 4 It is a schematic diagram of the IGBT chip-to-FWD chip coupling thermal impedance measurement circuit of the present invention, Figure 5 It is a schematic diagram of the FWD chip to IGBT chip coupling thermal impedance measurement circuit of the present invention, Image 6 It is a schematic diagram of the heating of the IGBT chip and the temperature rise curve of the FWD chip in the present invention, Figure 7 It is a schematic diagram of the heating of the FWD chip and the temperature rise curve of t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com