Straight gear temperature field prediction method based on thermal network model

A technology of thermal network model and prediction method, which is applied in the field of prediction of spur gear temperature field based on thermal network model, and can solve problems such as complex thermal resistance determination process, failure to consider the influence of heat flow, and inaccurate results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

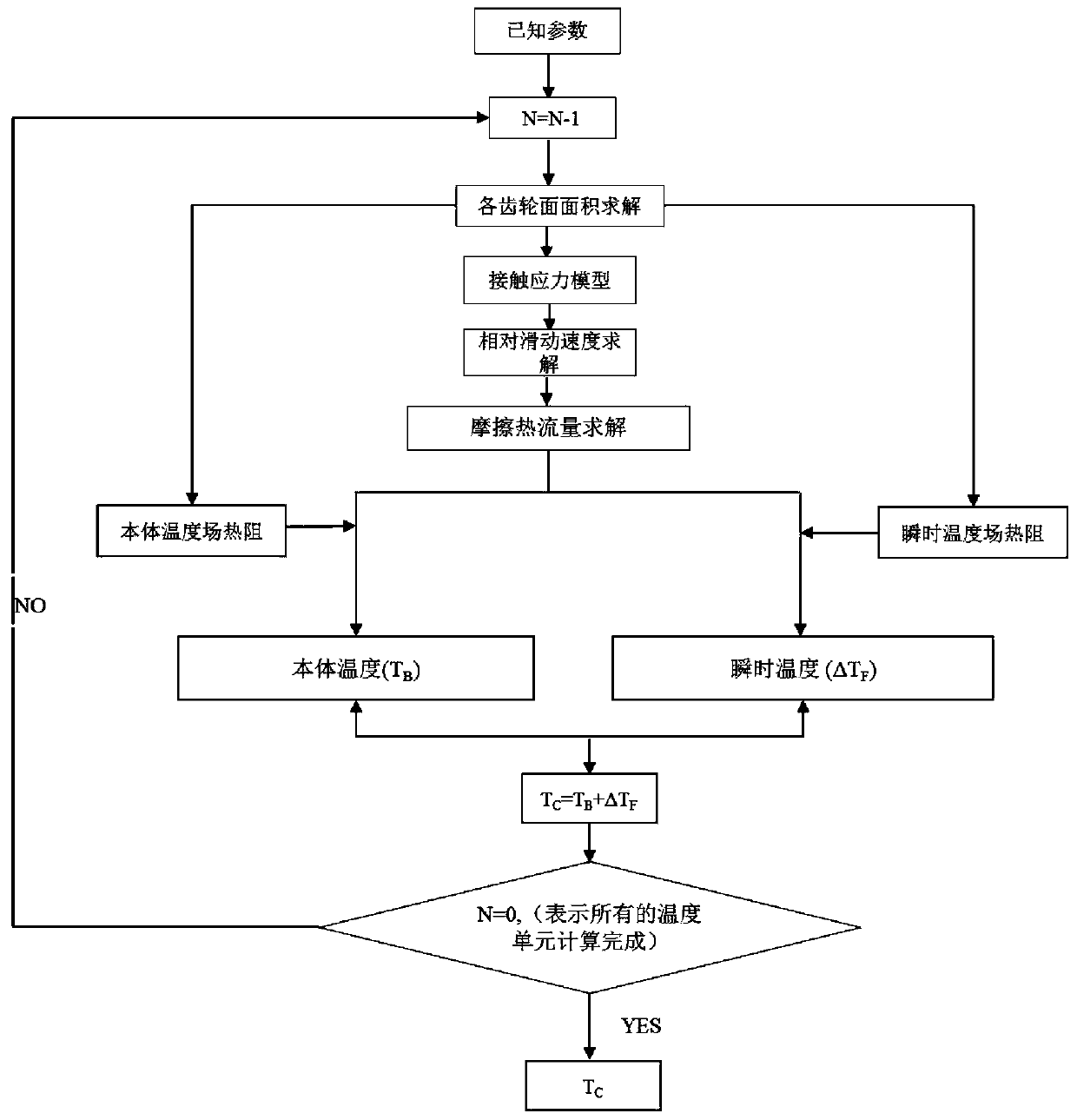

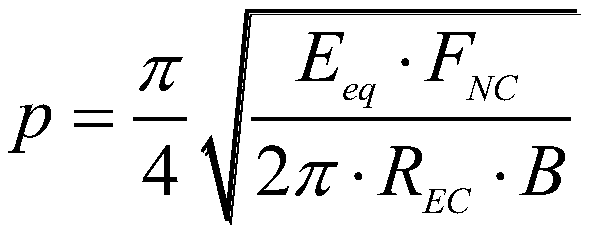

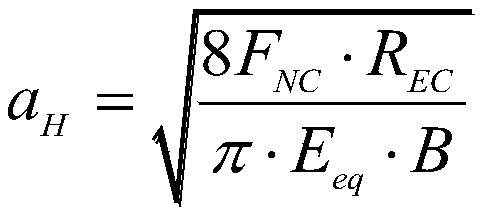

[0059] Such as figure 1 As shown, the present invention proposes a prediction method of spur gear temperature field based on thermal network model. First, the meshing area is averagely discretized into N areas, and each meshing point and the midpoint of the meshing point along the tooth thickness direction are taken as temperature nodes, and each discrete area is equivalent to a temperature unit, and each temperature unit passes The thermal resistance connection between each temperature node constitutes a thermal network model, where the thermal resistance includes convective heat transfer thermal resistance and thermal conduction thermal resistance. Then, based on the Hertzian contact theory, the contact pressure and relative sliding velocity are solved to obtain the frictional heat flow; according to the heat transfer theory, the temperature field distribution of the spur gear tooth surface is obtained by establishing the relationship between the frictional heat flow and the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com