Life prediction method of IGBT device based on semi-physical simulation platform

A technology of semi-physical simulation and life prediction, which is applied in the fields of instruments, special data processing applications, electrical digital data processing, etc., and can solve the problems of high investment cost, low practicability, and low accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

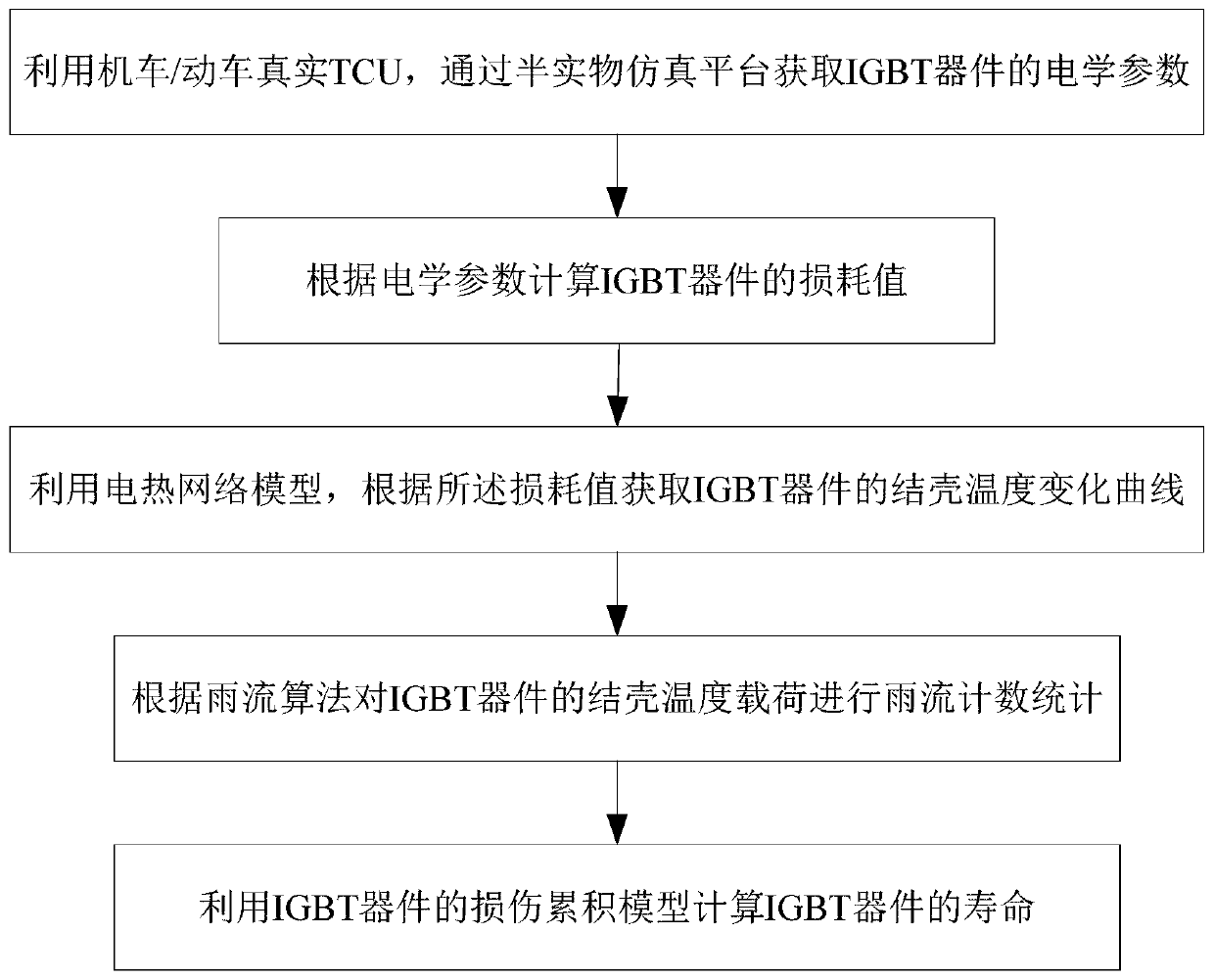

[0081] see figure 1 As shown, the present invention provides a kind of life prediction method of the IGBT device based on hardware-in-the-loop simulation platform, specifically comprises the following steps:

[0082] 1) Use the real TCU of the locomotive / motor car to obtain the electrical parameters of the IGBT device through the semi-physical simulation platform;

[0083] 2) calculating the loss value of the IGBT device according to the electrical parameters;

[0084] 3) using the electrothermal network model to obtain the junction temperature variation curve of the IGBT device according to the loss value;

[0085] 4) Perform rainflow counting statistics on the crust temperature load of the IGBT device according to the rainflow algorithm;

[0086] 5) Use the damage accumulation model of IGBT devices to calculate the lifetime of IGBT devices.

[0087] Further, step 1) uses the real TCU of the locomotive / motor car to obtain the electrical parameters of the IGBT device throug...

Embodiment 2

[0143] On the basis of Example 1, Infineon’s life prediction solution takes into account ΔT j (junction temperature change), ΔT c (Case temperature change) and the effect of device switching frequency on life. The Weibull failure formula is used to calculate the power cycle life / thermal cycle life of the device, and finally the final life prediction value of the device is obtained by integrating the power cycle life and thermal cycle life.

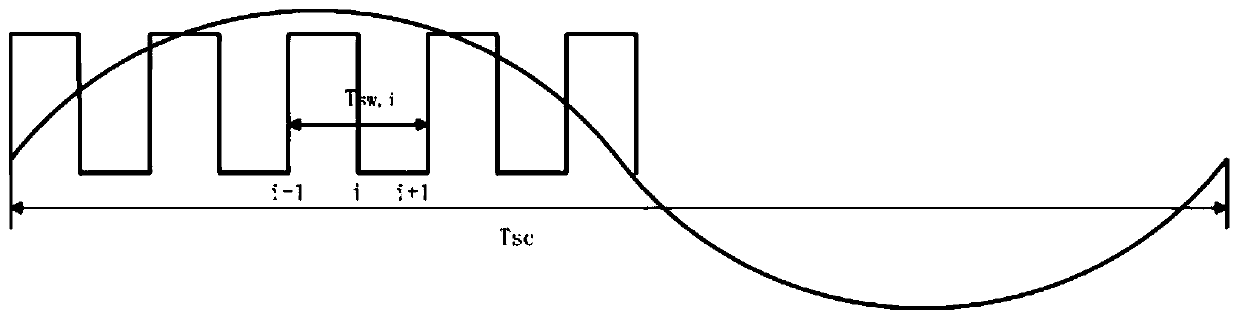

[0144] Taking the new eight-axle locomotive as an example, the half-physical simulation obtains the mission curve Figure 5 As shown, the temperature load change (temperature change amplitude, quantity, and average temperature) after rainflow counting is shown in Figure 6. Figure 6(a) is the change diagram of junction temperature load after rainflow processing, and Figure 6(b) is Shell temperature load change diagram after stream processing:

[0145] Among them, CH1: four-quadrant U-phase upper tube pulse; CH2: four-quadrant Uab voltage...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com