Method for intelligently monitoring abnormal operation state of equipment

A technology for operating status and intelligent monitoring, applied in speech analysis, instrument, character and pattern recognition, etc., can solve problems such as limited equipment types, difficulty in measuring complex equipment and transmission of high-frequency signals, and demanding power supply layout.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

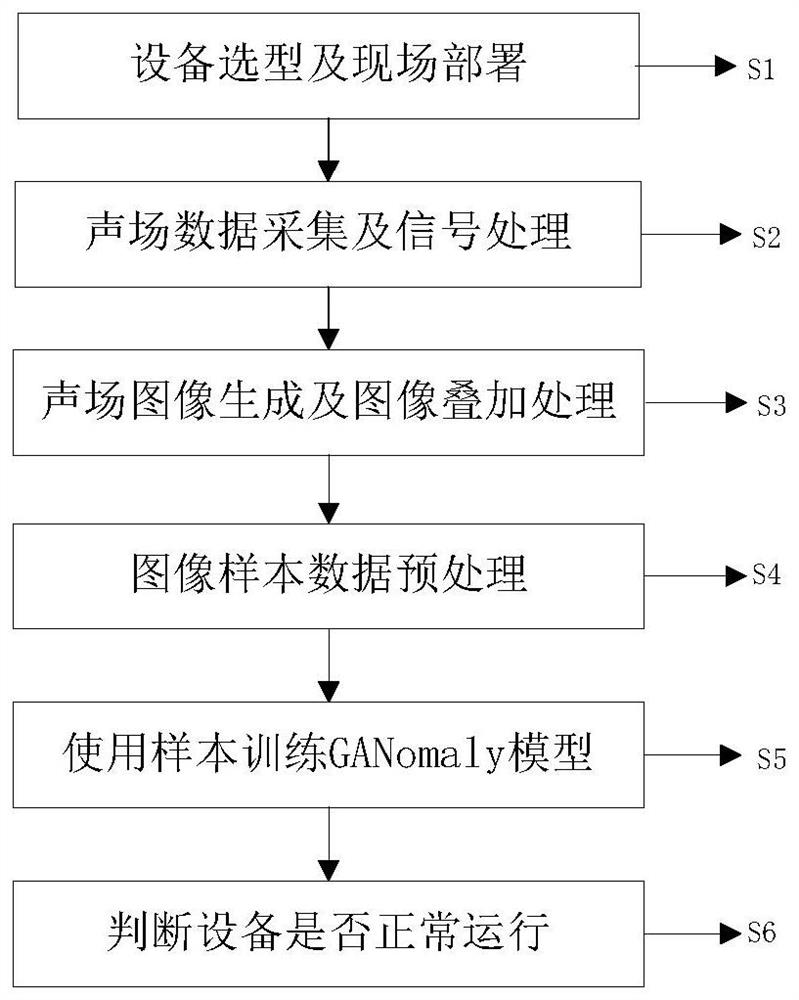

[0027] like figure 1 As shown, the method for intelligent monitoring of equipment abnormal operation status of the present invention includes the following steps:

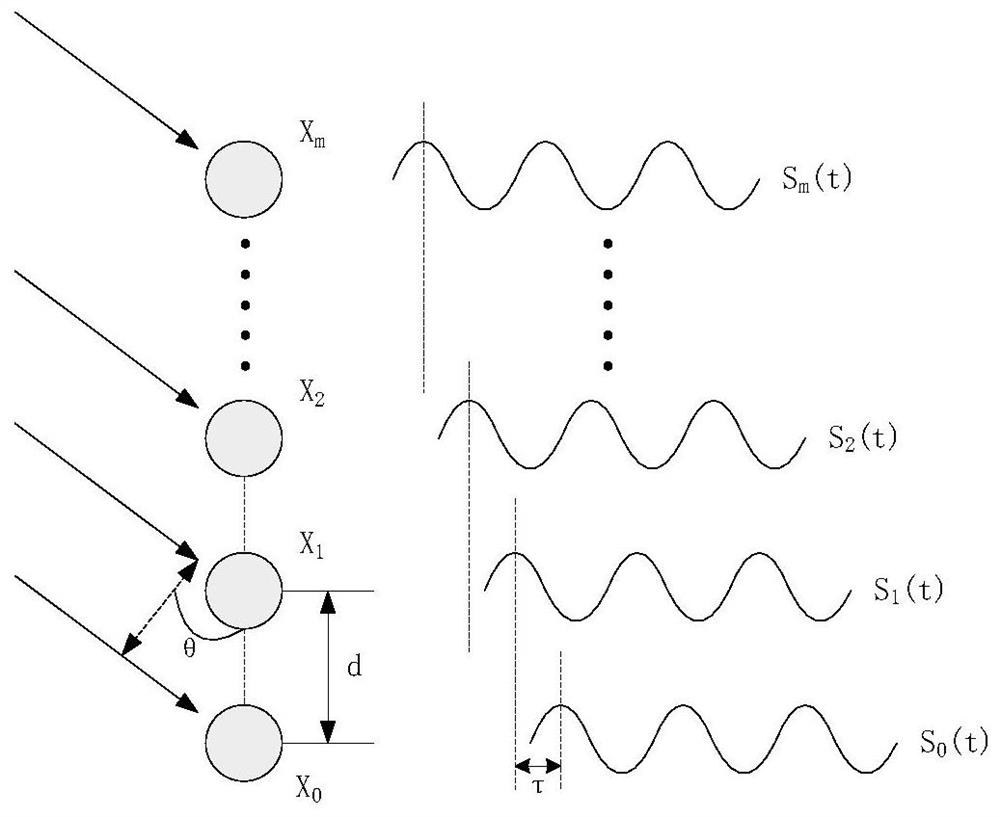

[0028] Step S1: Equipment selection and on-site deployment: According to the characteristics of the nuclear power equipment under test and the industrial scene where it is located, geometric parameters such as the number, aperture size, sensor element spacing, and spatial distribution form of the microphone array in the acoustic camera need to be considered. The microphone sensor requires a certain measurement frequency range and beamforming range, with a high signal-to-noise ratio, a high sampling frequency, and a suitable measurement distance. At the same time, the convenience of the sensor array in manufacturing, installation and transportation, as well as the radiation resistance characteristics of the microphone sensor in the special industrial environment of nuclear power should be considered;

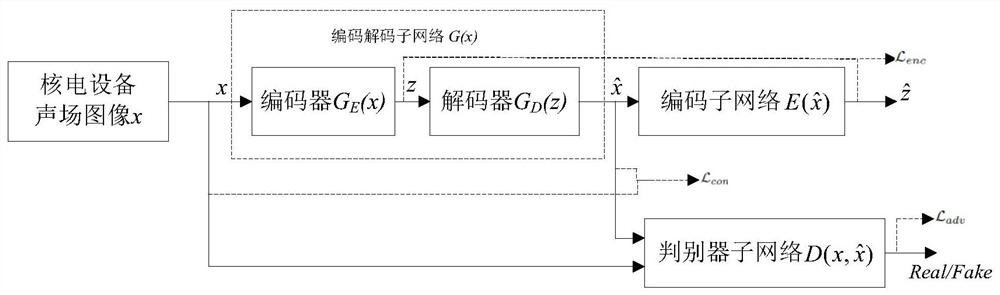

[0029] Step ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com