An inspection planning design method related to a three-dimensional digital assembly process

An assembly process, planning and design technology, applied in the direction of electrical digital data processing, calculation, special data processing applications, etc., to achieve the effect of easy operation, improved inspection efficiency, easy reading and uploading

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The invention is based on the MBPP system platform, realizes the association between the assembly process and the inspection process and optimizes the sequence of inspection steps.

[0022] The embodiments of the present invention are described in detail below in conjunction with the accompanying drawings. This embodiment is implemented on the premise of the technical solution of the invention, and detailed implementation methods and specific implementation processes are provided, but the protection scope of the present invention does not Limited to the following implementation examples.

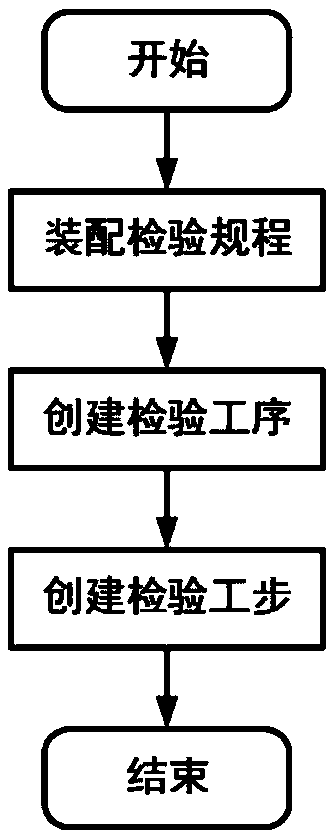

[0023] The specific implementation steps are as follows:

[0024] Step 1): The assembly process specification file is associated with the model. Select the corresponding assembly process specification file according to different parts, enter the assembly inspection process compilation module, and select the Process node that needs to be inspected in the assembly process tree to creat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com