Fuel coal and fuel gas united heat supply method

A combined heating and coal-fired technology, applied in heating methods, household heating, heating systems, etc., can solve the problems of small heating demand, difficult to achieve operating conditions, and not in line with the principle of social fairness, to reduce Heating energy consumption and cost, heating cost are close to the same, which is beneficial to social equity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

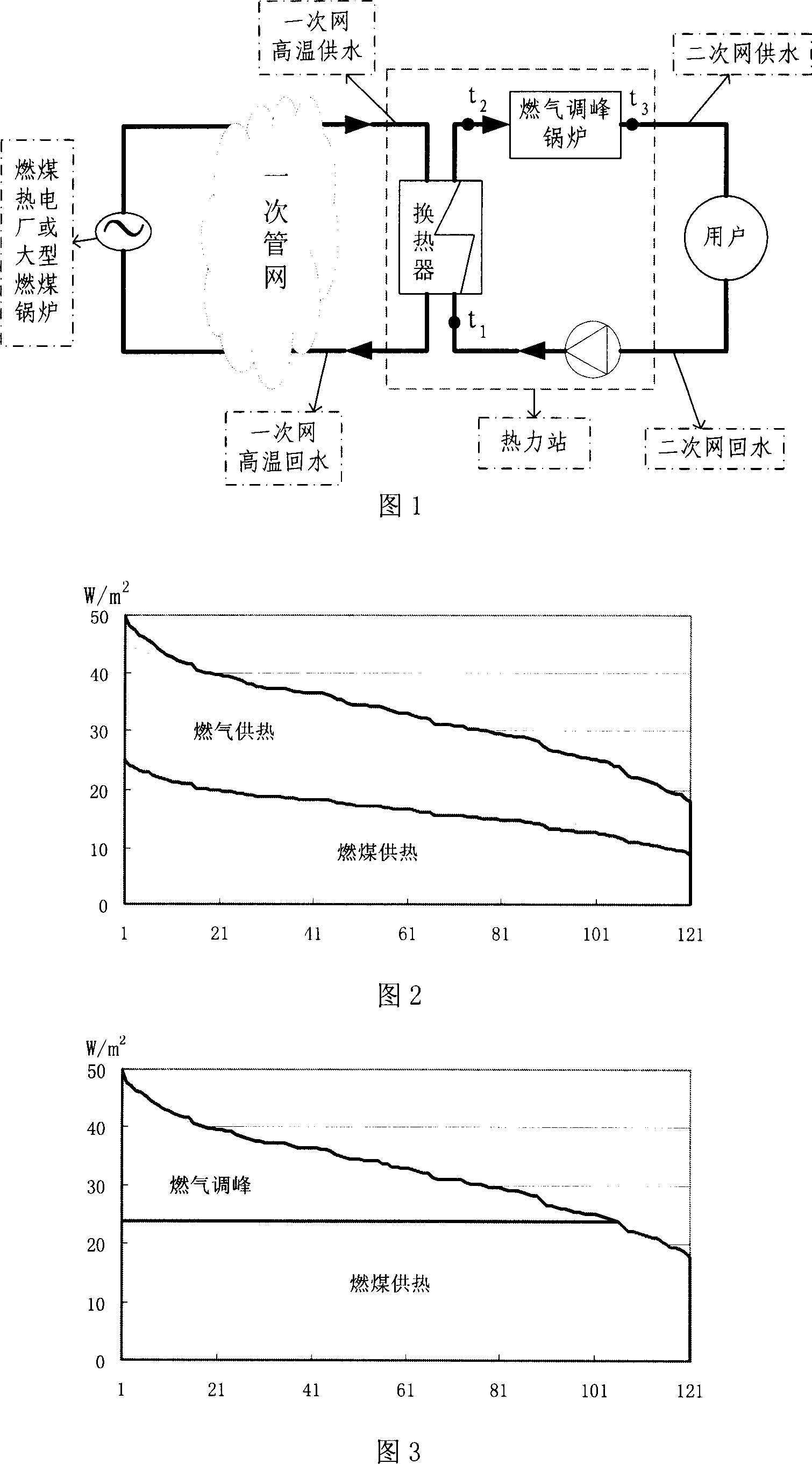

[0025] Referring to Figure 1, taking the implementation of coal-fired gas combined heating in a thermal power plant in Beijing as an example, the outdoor design temperature of heating is -9°C, the indoor design temperature is 18°C, and the design supply and return water temperature of the secondary network side is 80°C / 60°C. When the outdoor temperature is -9°C, the temperature difference between the inlet and outlet of the heat exchanger and the temperature difference between the inlet and outlet of the peak-shaving boiler are both 10°C, that is, the thermal power plant and the peak-shaving boiler each bear 50% of the heat, and as the external temperature rises to -6 ℃, the heat demand at the end decreases, but the heat provided by the thermal power plant remains unchanged, and the temperature difference between the inlet and outlet of the heat exchanger is still 10℃, but the heat supply of the peaking boiler is reduced, and the temperature difference between the inlet and outl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com