Drying system using overlapped multi-connected type heat pumps

A drying system and multi-connection technology, applied in the field of drying system of lithium battery pole piece coating machine, can solve the problem of high power consumption of fans, save workshop space, reduce heat loss and power consumption of fans, and reduce production costs Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

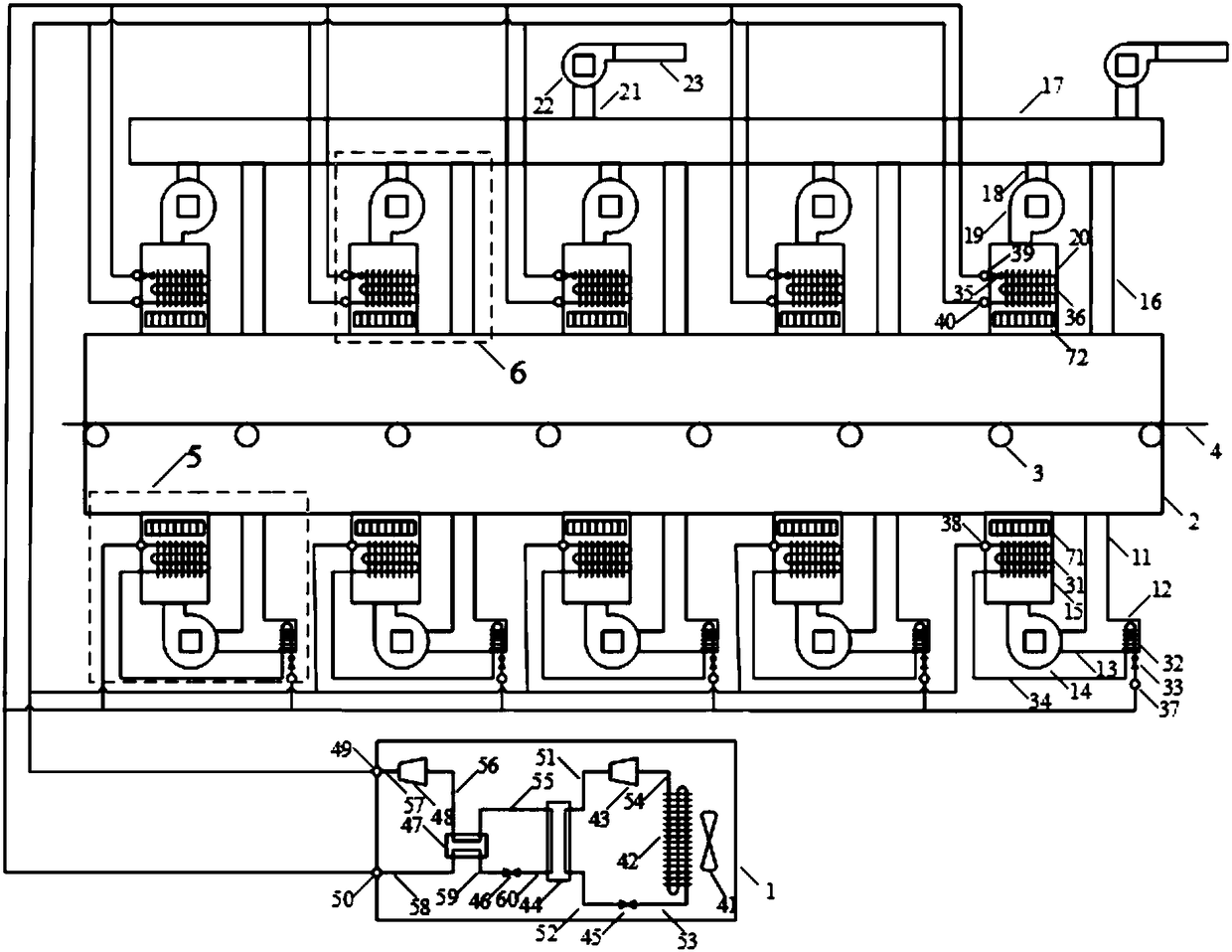

[0040] A drying system using cascade multi-connected heat pumps, such as figure 1 As shown, it includes a drying tunnel 2, a lower heating assembly 5, an upper heating assembly 6, and a heat pump host 1. The lower heating assembly 5 is located below the drying tunnel 2, and several are arranged along the length direction of the drying tunnel 2 for providing hot air to the drying tunnel 2. The upper heating assembly 6 is located above the drying tunnel 2, and several are arranged along the length direction of the drying tunnel 2 for To provide hot air to the drying tunnel 2, one heat pump host 1 is provided, connected to each lower heating assembly 5 and upper heating assembly 6, and supplies heat to each lower heating assembly 5 and upper heating assembly 6 respectively.

[0041] In this embodiment, the heat pump host 1 is provided with a cascaded heat pump system, and its main structure includes a low-temperature heat pump cycle and a high-temperature heat pump cycle. In one...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com