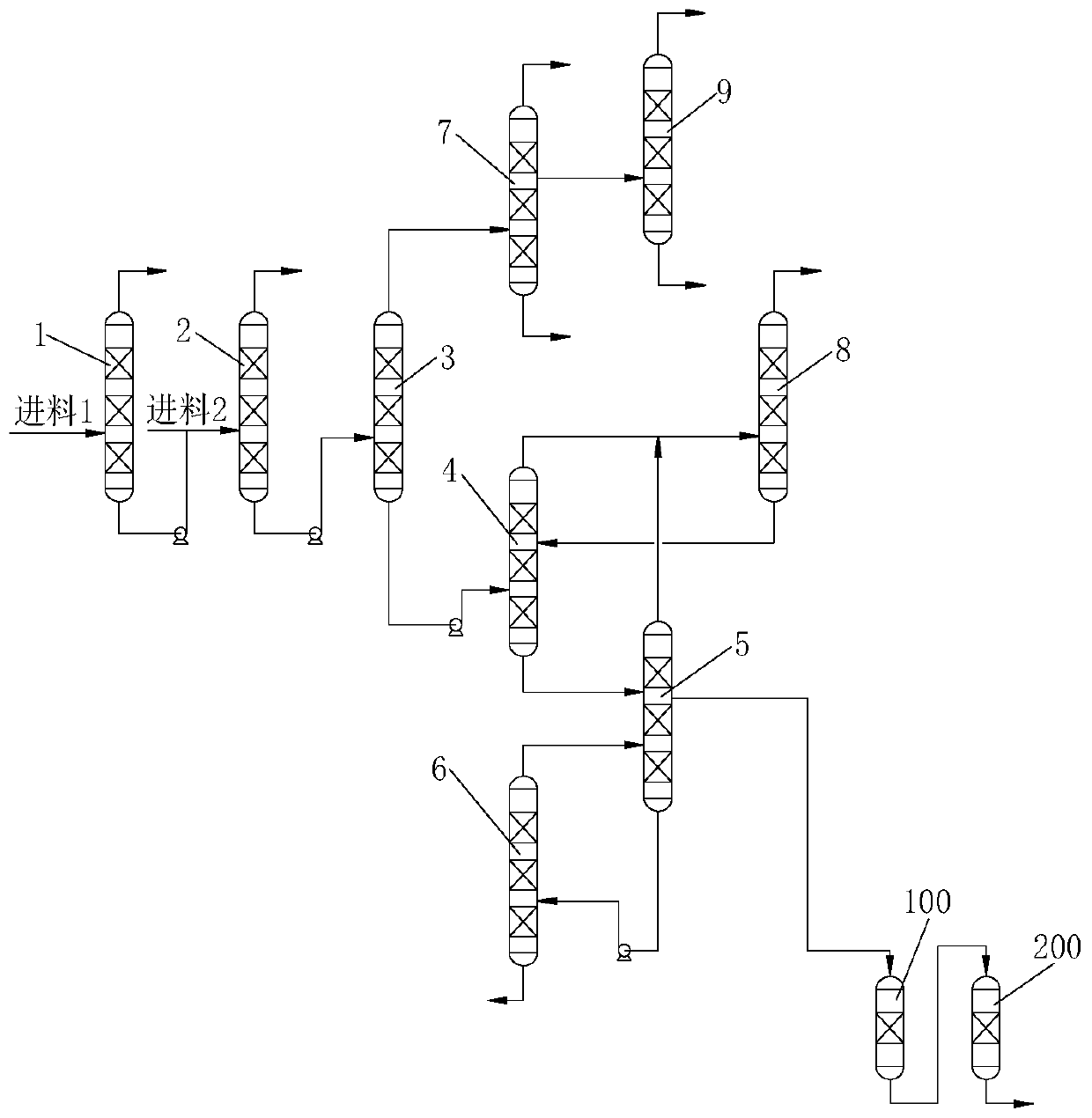

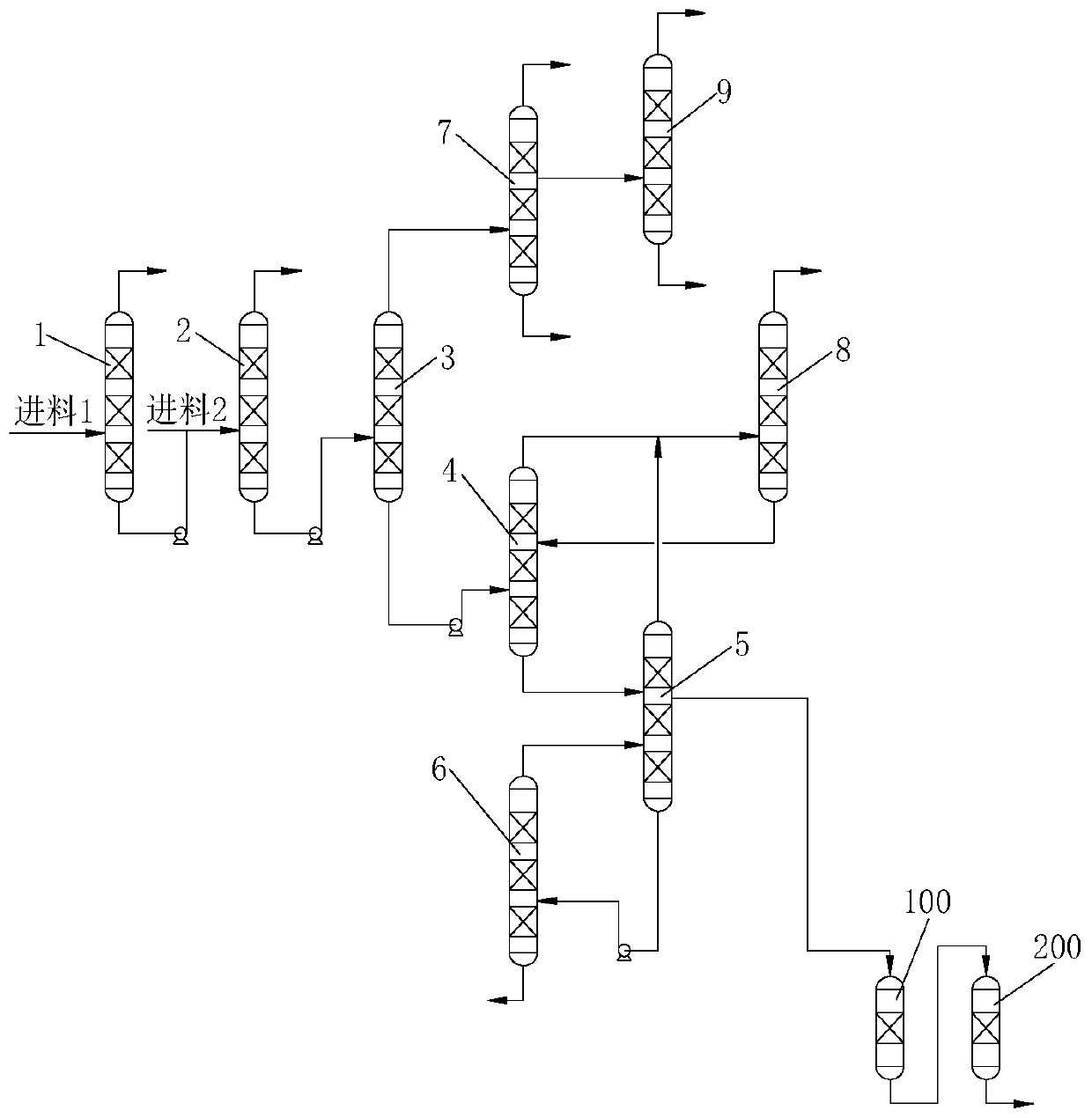

System and method for ethylene glycol rectification in production of ethylene glycol from syngas

A technology of ethylene glycol and synthesis gas, which is applied in the field of ethylene glycol rectification, can solve the problems of substandard products and high energy consumption in the rectification section, and achieve the effect of improving the recovery rate and reducing the steam consumption.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0047] A method for the rectification of ethylene glycol in the production of ethylene glycol from synthesis gas, comprising the following steps:

[0048] (1) Crude ethylene glycol containing more methanol from the hydrogenation unit (for example, 87.6% methanol, 0.8% ethanol, 0.1% 1,2-butanediol, 10.9% ethylene glycol, 0.5% water) After heat exchange between the heat exchanger and the ethylene glycol product, it enters the lower part of the methanol recovery tower A. The reboiler of the methanol recovery tower A uses 0.05MPaG steam, and the refined methanol is extracted from the top of the tower by vacuum distillation, and enters the methanol recovery tower A through condensation. Refined methanol storage tank, the mixed solution containing ethylene glycol in the tower tank enters the methanol recovery tower B;

[0049] (2) Crude ethylene glycol containing more ethylene glycol from the hydrogenation unit (for example, methanol 9.8%, ethanol 0.1%, 1,2-propanediol 0.1%, 2,3-but...

PUM

| Property | Measurement | Unit |

|---|---|---|

| transmittivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com