Temperature calibrating apparatus for IGBT power module chip and temperature correction method thereof

A technology of power module and calibration device, applied in thermometers, measuring devices, thermometer testing/calibration, etc., can solve problems such as adverse effects of computing resources, consumption of computing resources, etc., to achieve real-time working results and eliminate losses

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

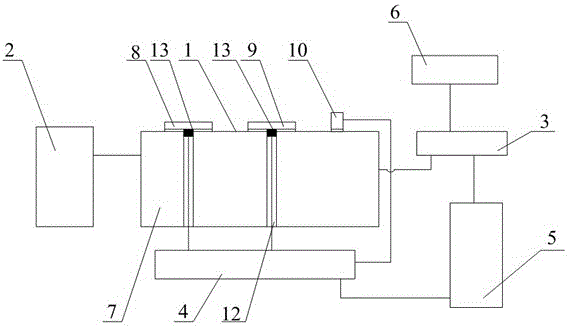

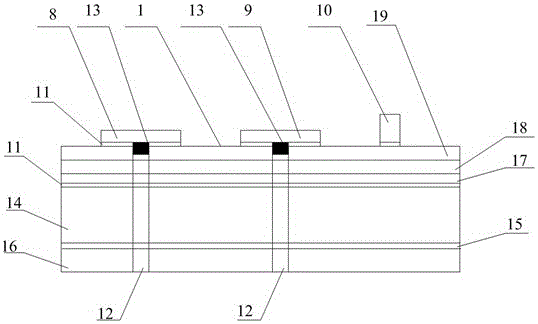

[0036] Including an IGBT power module, the IGBT power module 1 includes an IGBT chip 8, a diode chip 9 and an NTC thermistor 10; the IGBT chip 8, the diode chip 9 and the NTC thermistor 10 are respectively fixed on the heat dissipation base 7 by soldering 11 Above; the lower end of the IGBT chip 8 and the diode chip 9 is provided with a cloth sensor through hole 12 longitudinally penetrating the heat dissipation substrate 7; the connection between the IGBT chip 8 and the diode chip 9 and the cloth sensor through hole 12 is respectively provided with a temperature sensor 13; The IGBT power module 1 is connected to the load 2 , the driver 3 and the data acquisition instrument 4 respectively; the driver 3 and the data acquisition instrument 4 are respectively connected to the upper computer 5 ; the driver 3 is connected to the power supply 6 . The above-mentioned heat dissipation base 7 includes a copper substrate 14, the lower surface of the copper substrate 14 is provided with a...

Embodiment 2

[0039] Through the device described in Embodiment 1, the chip temperature of the IGBT power module is corrected.

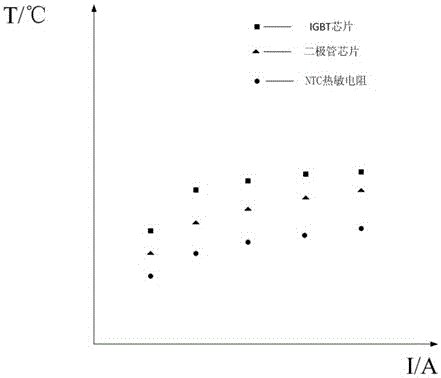

[0040] Under certain test conditions, such as a certain power supply voltage, a certain ambient temperature, etc., and under certain control of the upper computer 5, such as a certain control frequency, a certain modulation mode, etc., perform temperature calibration. Modulation mode, under the control frequency of 10K, record the NTC temperature of the IGBT power module 1 under the different phase output current of the inverter, the temperature sensor 13 collects the temperature of the IGBT chip 8 and the temperature sensor 13 collects the temperature of the diode chip 9; the collected IGBT chip The temperature calibration data MAP is formed by the NTC acquisition temperature of the module corresponding to the junction temperature of the diode chip.

Embodiment 3

[0042] Replace the power supply voltage, repeat the test steps described in Example 2, and form the data MAP of NTC temperature and chip temperature under different power supply voltages. In the same way, the data MAP of NTC temperature and chip temperature can be formed under different control frequencies, which can be designed according to the actual application.

[0043] In practical applications, the inverter directly collects the temperature of the NTC in the IGBT power module 1, and the overtemperature junction temperature of the IGBT chip 8 and the diode chip 9 is obtained by looking up the calibrated temperature data MAP.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com