High-power device power cycle test junction temperature monitoring method, device and system

A high-power device, power cycle technology, applied in the direction of measuring devices, circuit breaker testing, instruments, etc., can solve the problem of unable to monitor the junction temperature of high-power devices

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

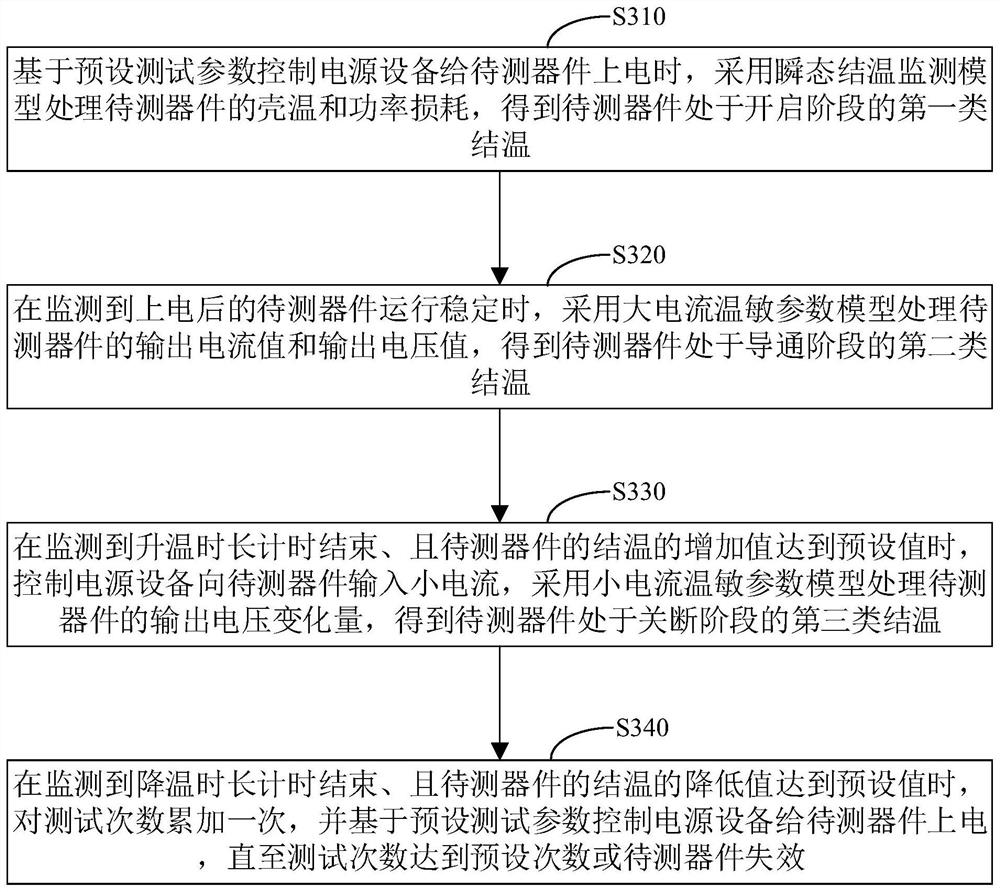

[0046] In order to make the purpose, technical solution and advantages of the present application clearer, the present application will be further described in detail below in conjunction with the accompanying drawings and embodiments. It should be understood that the specific embodiments described here are only used to explain the present application, and are not intended to limit the present application.

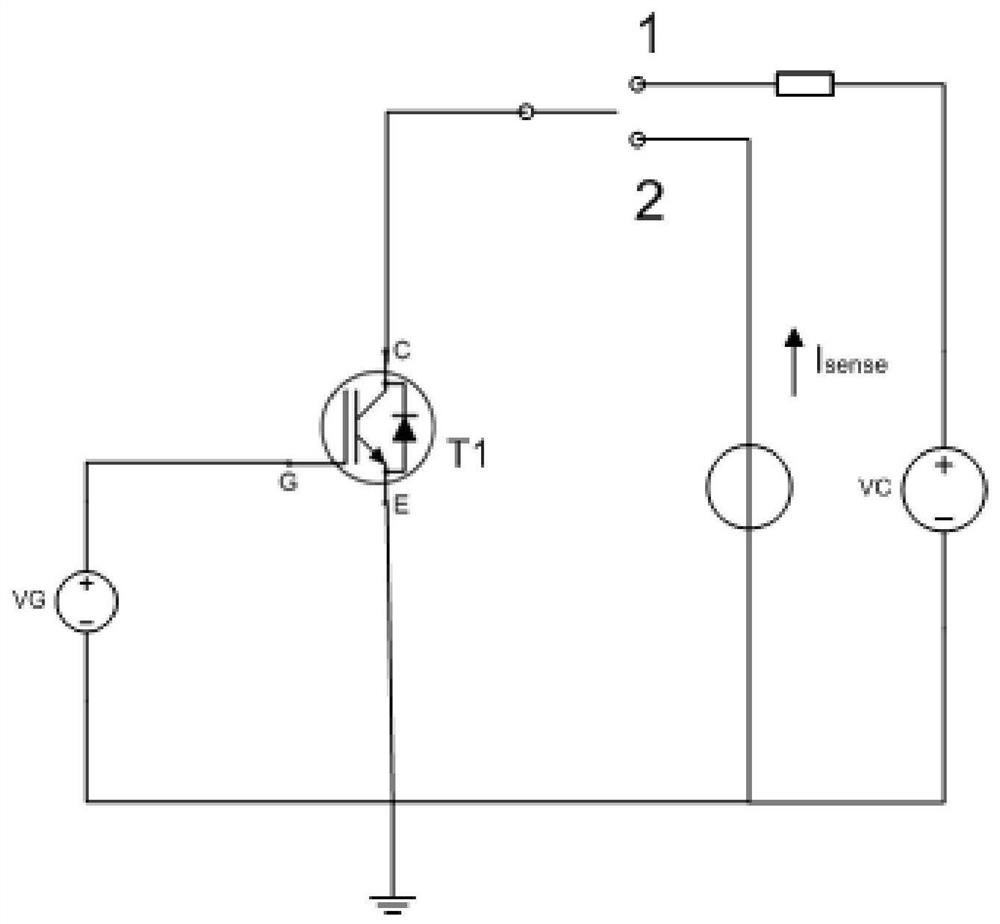

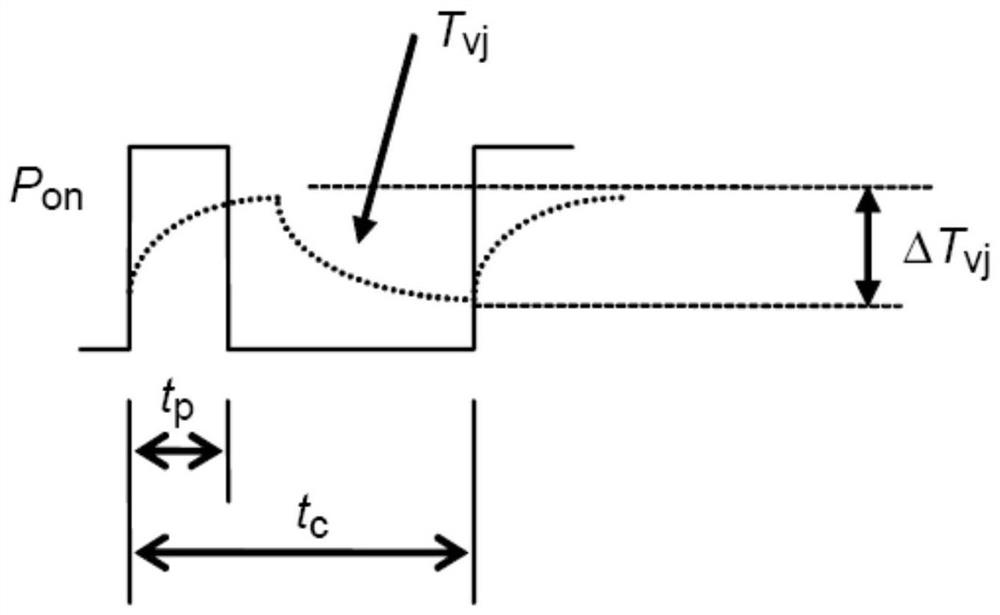

[0047] In a specific application scenario of the high-power device power cycle test junction temperature monitoring method of this application:

[0048] In the traditional technology, the small current injection conduction voltage drop method is usually used to measure the junction temperature during the power cycle test. The specific steps are: firstly apply a large heating power to the device to cause the device to heat up, and then cut off the heating power instantaneously, apply A very small test current (usually 10-100mA) that does not cause self-heating temperature r...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com