High-power flip LED chip with temperature monitoring function and preparation method thereof

A LED chip, high-power technology, applied in the direction of electrical components, circuits, semiconductor devices, etc., can solve the problems of LED chip failure, unable to effectively judge local overheating, etc., achieve real-time monitoring, solve the effect of local overheating failure problems

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

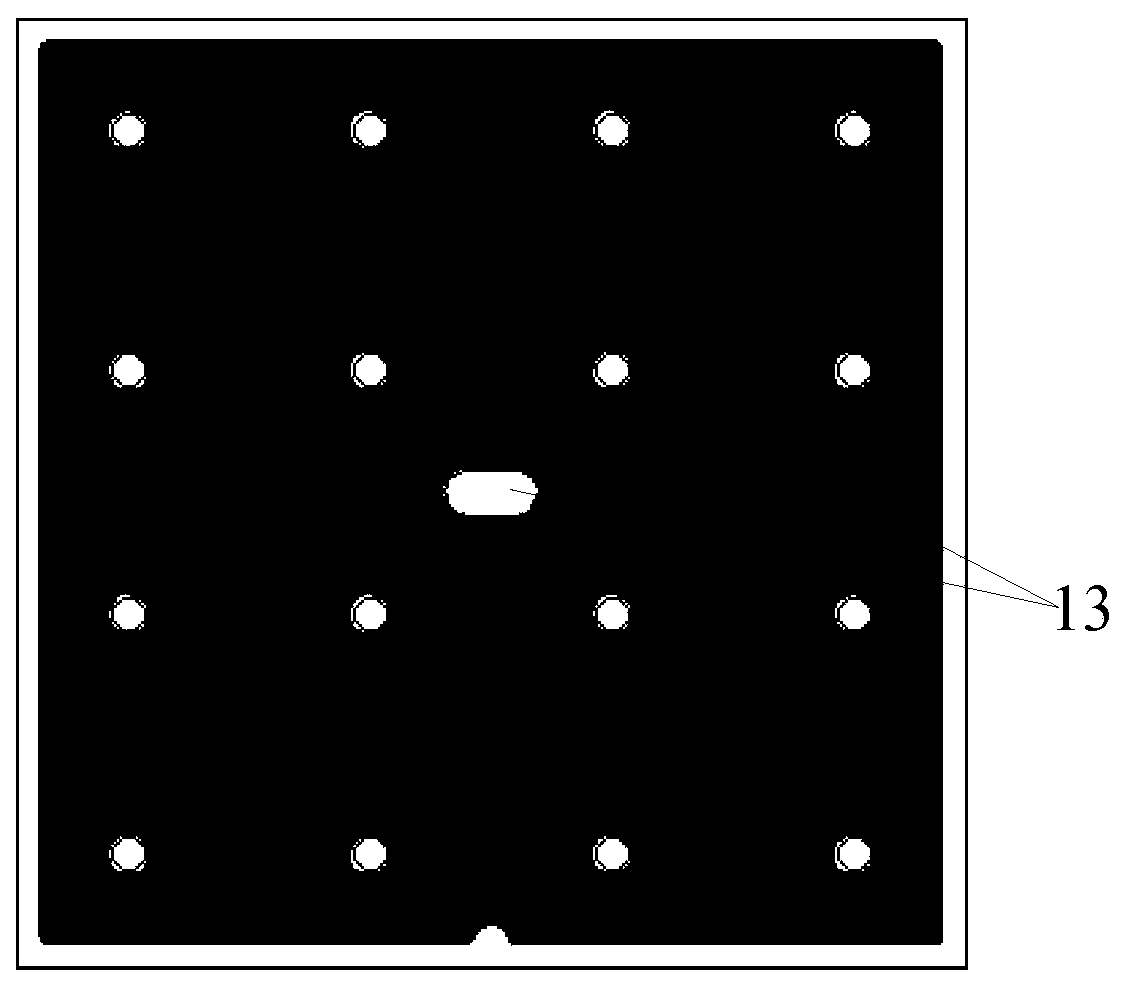

[0038] The present invention will be further described below in conjunction with specific drawings and embodiments.

[0039] Embodiments of the present invention propose a method for preparing a high-power flip-chip LED chip with temperature monitoring. In the following method, wafer refers to the structure of the intermediate step before the LED chip is completed;

[0040] The method comprises the steps of:

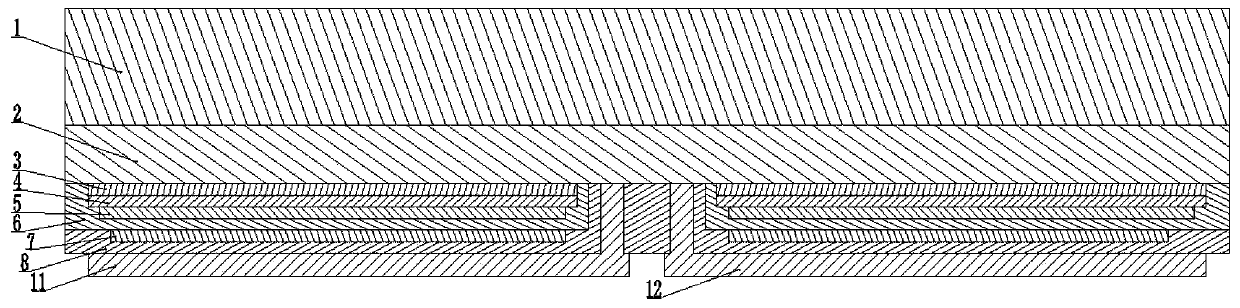

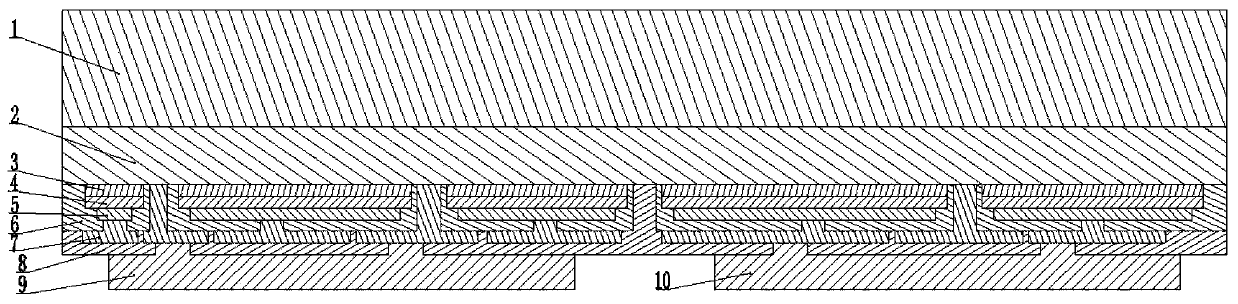

[0041] Step 1, using MOCVD equipment to sequentially grow N-GaN layer 2, quantum well layer 3 and P-GaN layer 4 on the sapphire substrate layer 1 to form a complete LED epitaxial structure;

[0042] By changing the temperature and the composition of In and Al in the growth process of the quantum well layer 3, the emission wavelength can be changed;

[0043] Step 2, using the positive photoresist mask method to make a mask pattern, the blank area on the mask pattern corresponds to the channel to the N-GaN layer 2, and the N-GaN layer corresponding to the blank area of ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com