Method for over-temperature protection through monitoring power tube junction temperature by collecting anode penetration current

A technology of over-temperature protection and current monitoring, applied in the direction of amplifier protection circuit layout, etc., can solve the problem of destroying the normal operation of the circuit, and achieve the effect of improving reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

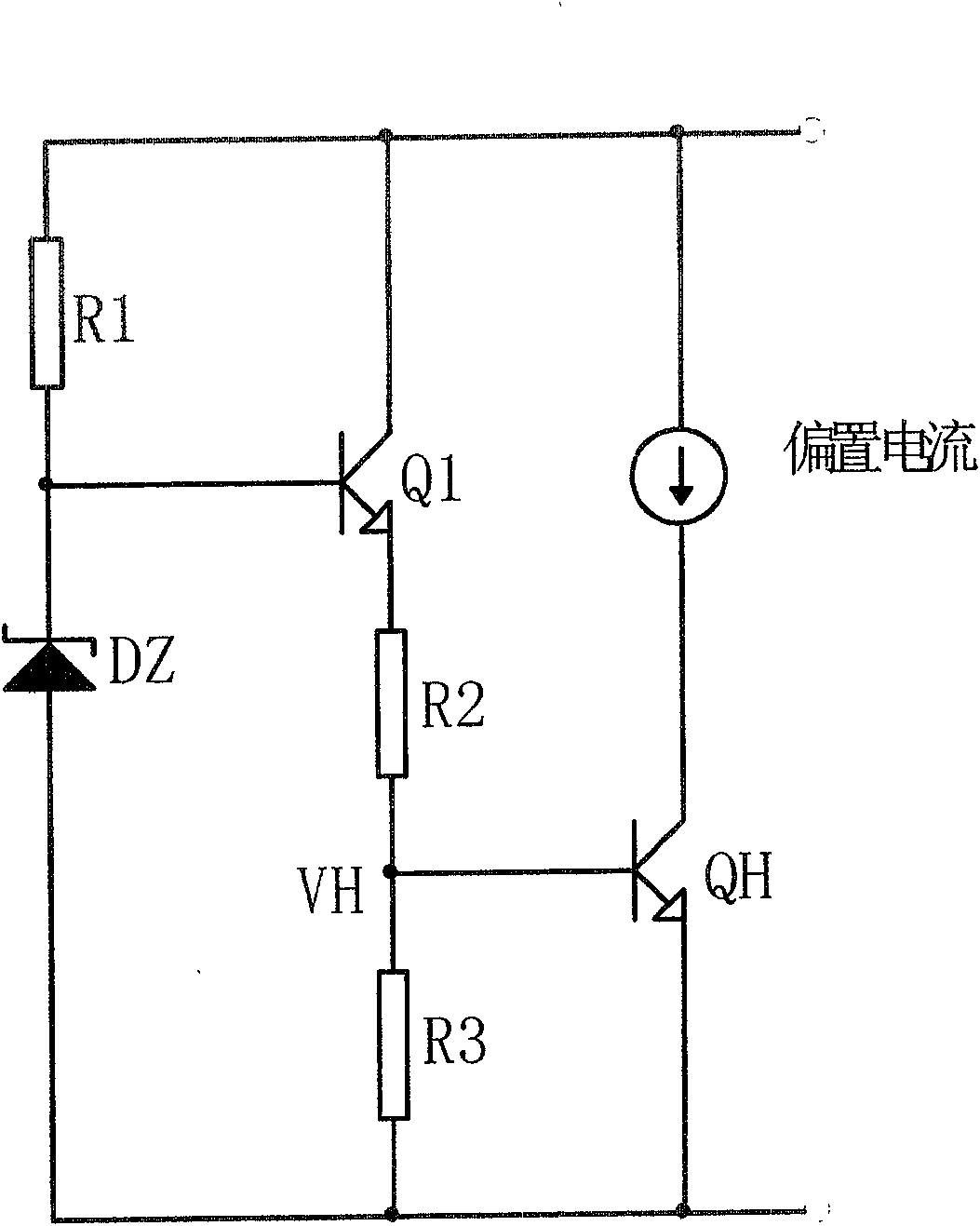

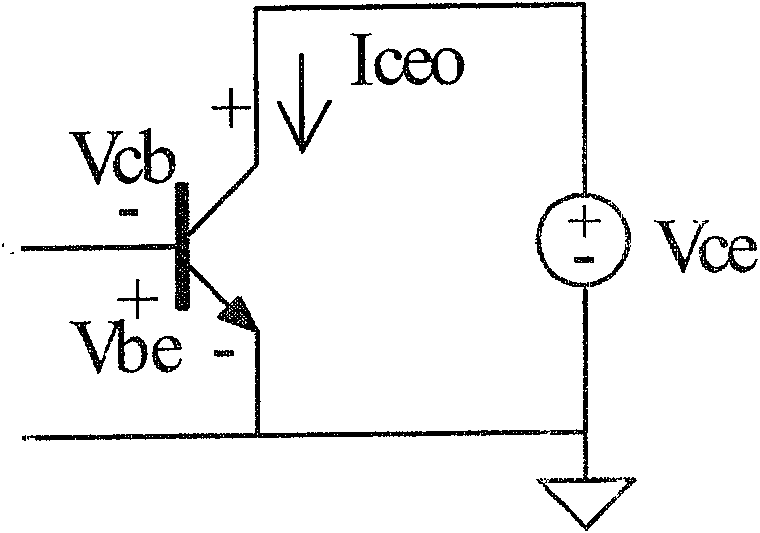

[0027] For thermal sampling, the leakage current of the ICEO increases with the temperature as the power of 2. When the temperature rises by 100 degrees, the current can increase by 1000 times. At this time, the leakage current cannot be ignored and can reach uA level current.

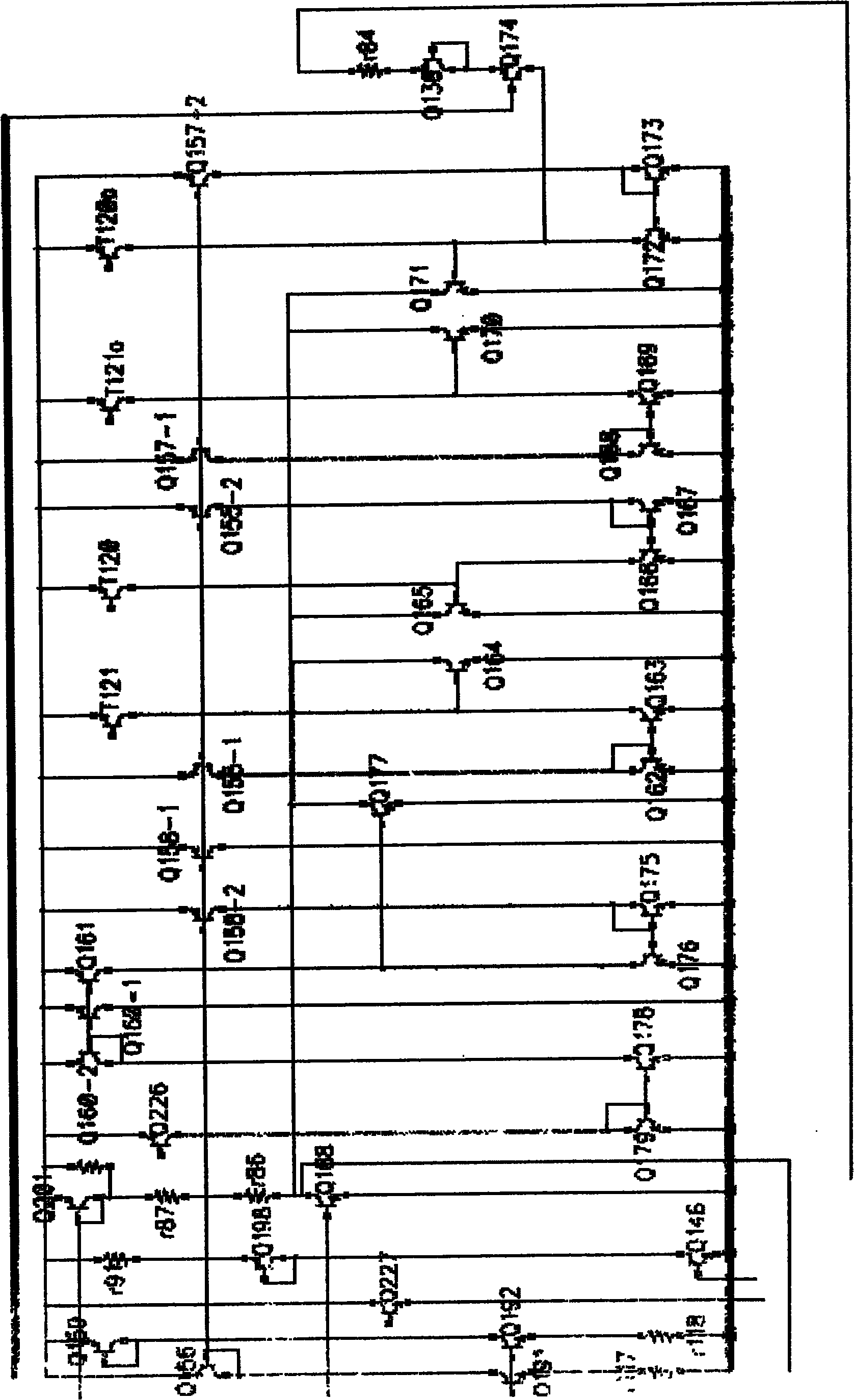

[0028] During normal operation, the charging tube Q222 charges the oscillating capacitor C7 to the power supply. Usually, the upper plate of the oscillating capacitor C7 is positively charged, and the lower plate is negatively charged. The plate is at the same potential as the upper plate, and the discharge tube Q207 always has current. When charging the oscillating capacitor C7, the discharge current ic3 is negligible. When discharging, the discharge tube Q207 is discharged, and the current of the discharge tube Q207 is very small. The entire cycle is mainly determined by the discharge time.

[0029] During the discharge process of the capacitor to the discharge tube Q207, the first level comparator Q...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com