Converter power cabinet

A power cabinet and converter technology, applied in the design field of the power cabinet cooling system, can solve the problems of partial discharge failure, reduced ventilation efficiency, reduced power density, etc., so as to improve device reliability, reduce device cost, and reduce fan pressure loss. small effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The following are specific embodiments of the present invention and in conjunction with the accompanying drawings, the technical solutions of the present invention are further described, but the present invention is not limited to these embodiments.

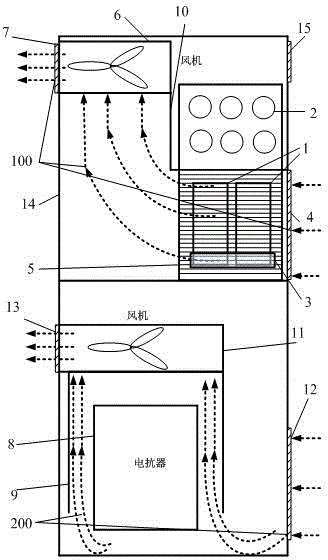

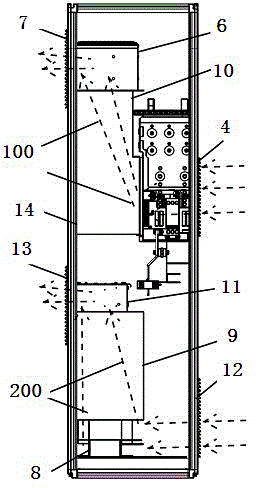

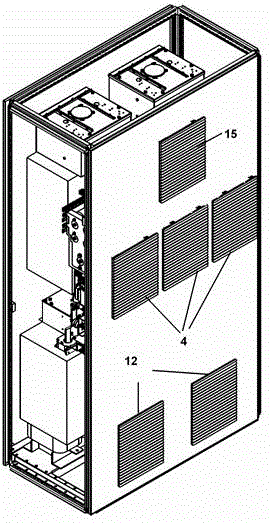

[0026] Such as figure 1 with figure 2 A power cabinet for a converter is shown, and the power cabinet is divided into two independent cooling air ducts, which are respectively a power module cooling air duct 100 and a reactor cooling air duct 200, and the power module cooling air duct It is surrounded by the first windshield 10 and the cabinet body 14, and the reactor cooling air duct 200 is surrounded by the second windshield 9 and the cabinet body 14, and the two air ducts are isolated from each other.

[0027] The reactor heat dissipation air duct 200 is provided with an air-cooled reactor 8 and a second fan 11, and the air-cooled reactor 8 is located below the second fan 11, and the third ventilation window 12 is loc...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com