Water-cooling fly ash sampling device of circulating fluid bed boiler

A circulating fluidized bed, sampling device technology, used in sampling devices, measuring devices, suspension and porous material analysis and other directions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

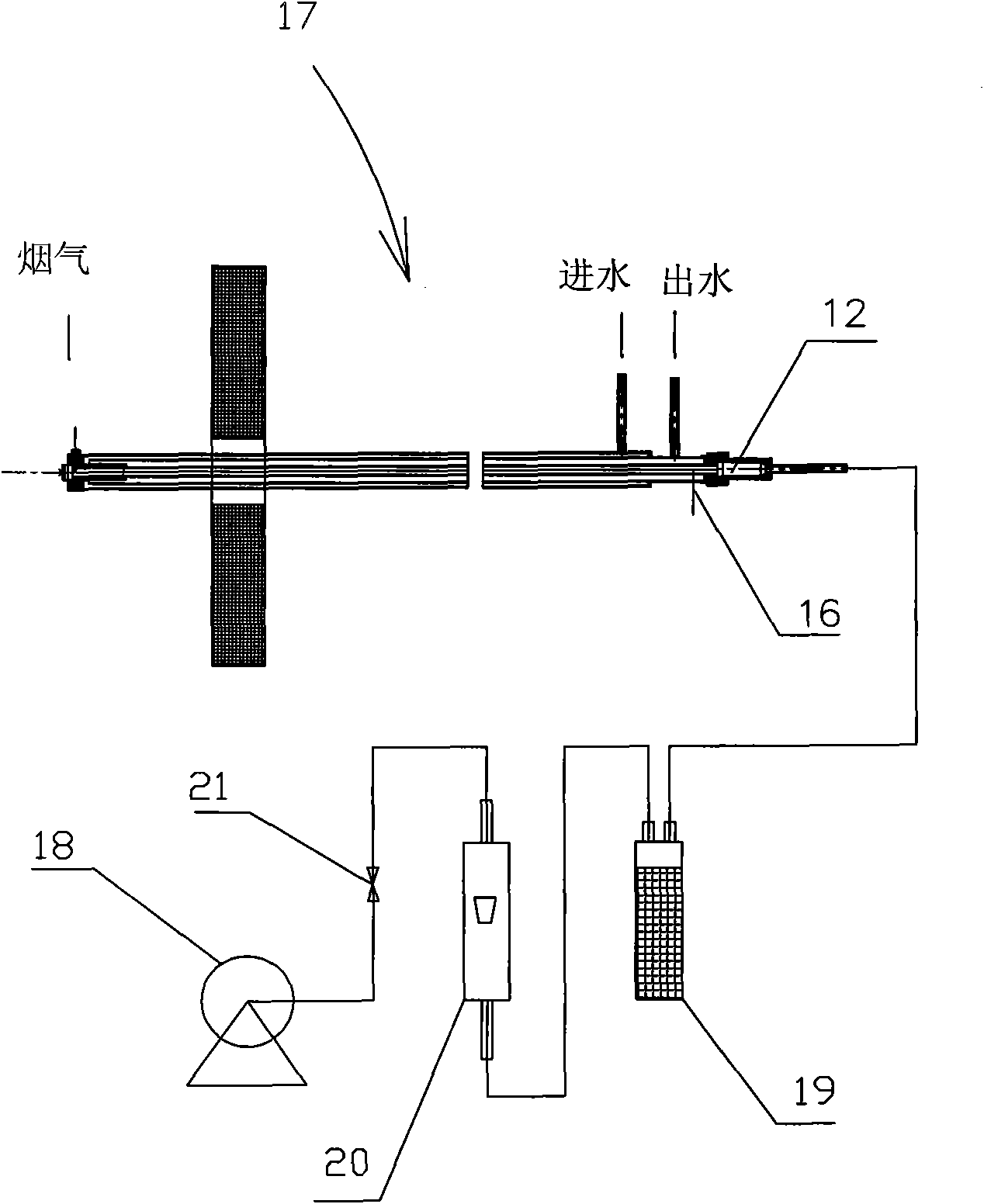

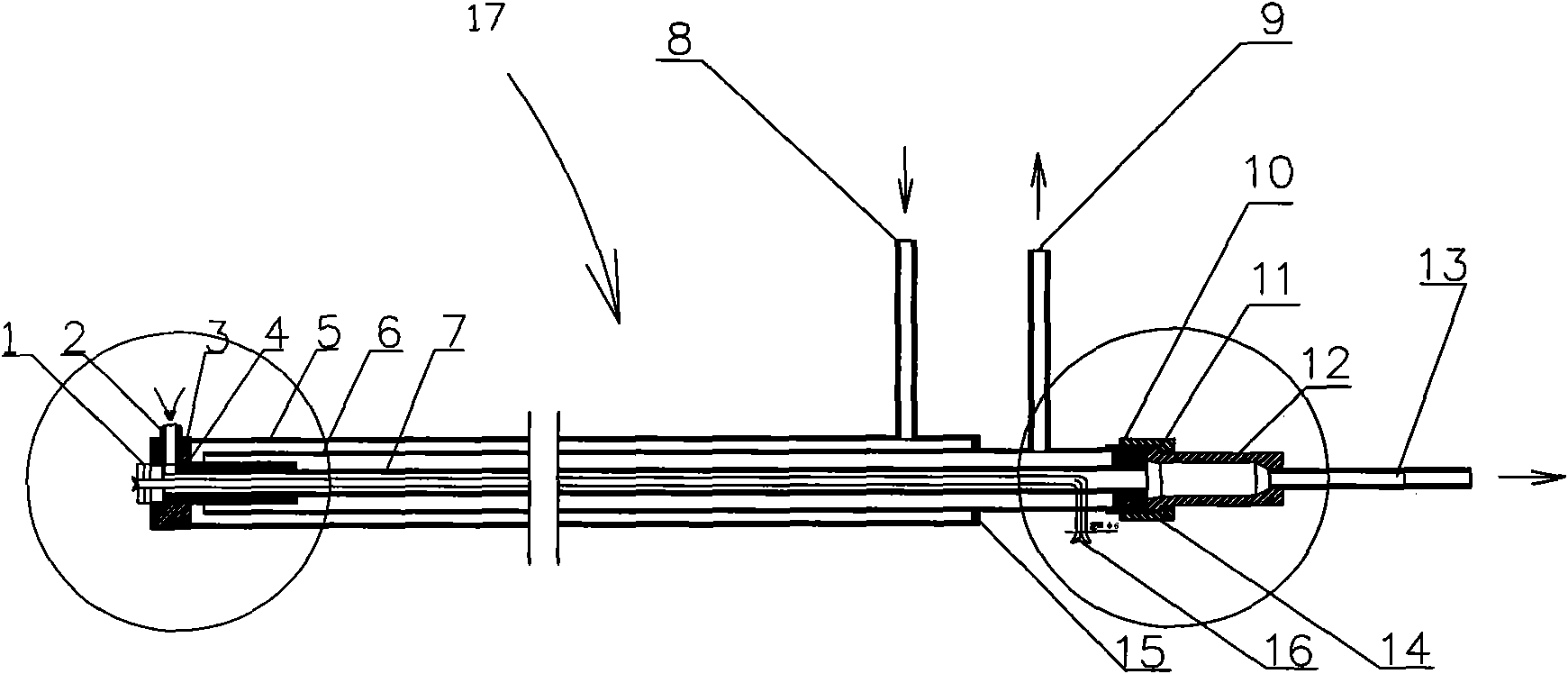

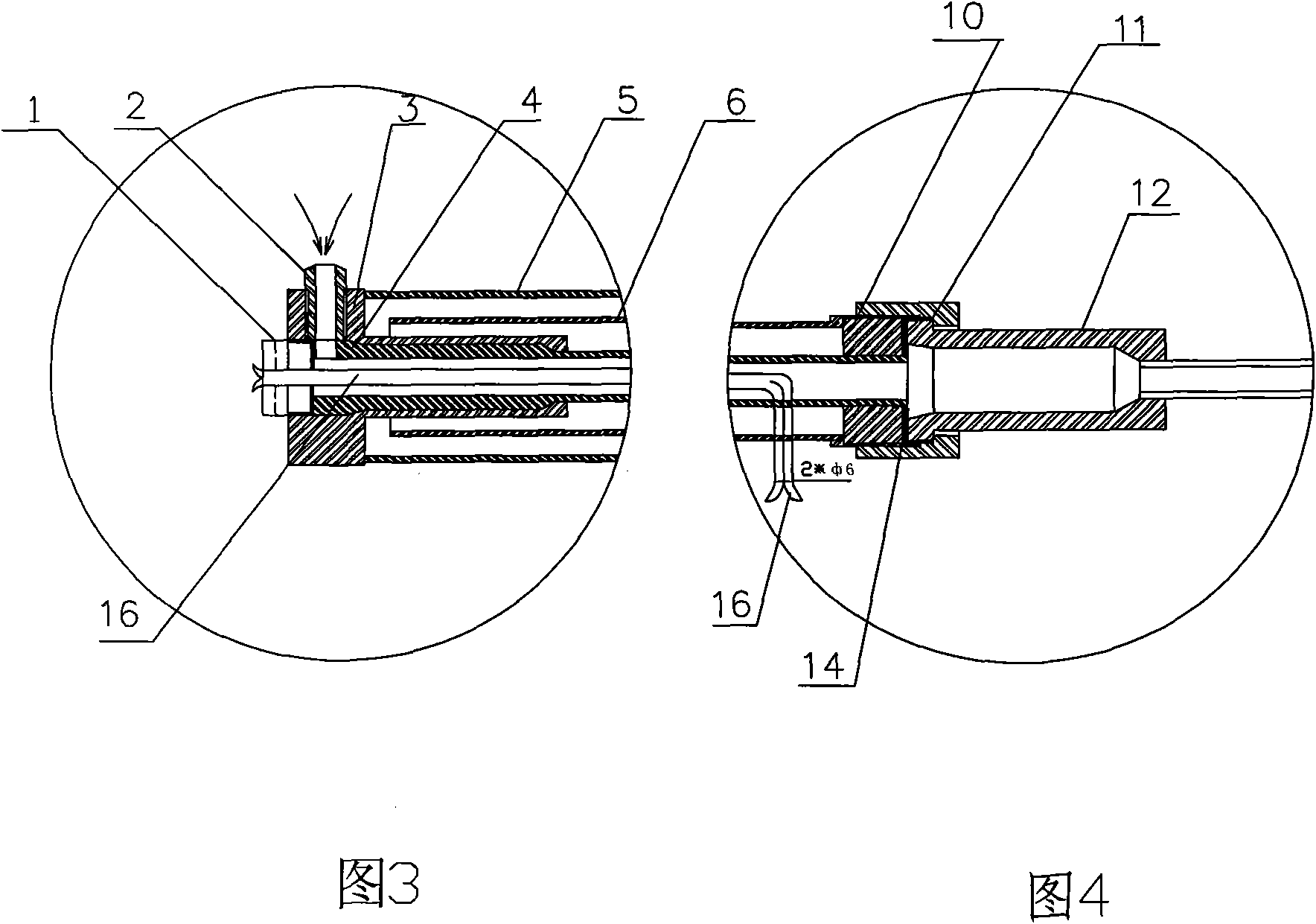

[0024] Such as Figures 1 to 4 The shown circulating fluidized bed boiler water-cooled fly ash sampling device is an embodiment of the present invention, comprising a sampling gun 17, and its structure is that a sampling head 2 is connected to the front end of a sampling pipe 7, and the sampling head has a smoke inlet and It communicates with the cavity of the sampling pipe 7, and the rear end of the sampling pipe 7 is provided with a sampling cylinder and a sampling connecting pipe for placing the sampling fly ash. There is a gap, the front end and the rear end of the backrest pipe pass through the sampling pipe 7, the front end is fixed by a plug 1, and the rear end is connected with the differential pressure measuring device.

[0025] The feature of the present invention is exactly that the sampling tube 7 is covered with a water-cooling sleeve for cooling water to pass through. There is a gap between the outer walls for the circulation of cooling water. The front ends of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com