PNIN/NPIP type SSOI TFET with abrupt tunneling junctions and preparation method thereof

A technology of tunneling junction and dry etching, which is applied in semiconductor/solid-state device manufacturing, diodes, semiconductor devices, etc., can solve the problems of limiting the tunneling probability of TFET devices, reducing the average sub-threshold slope, and small driving current, etc., to achieve Effects of suppressing bipolar effects, increasing the probability of tunneling, and reducing the forbidden band width

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

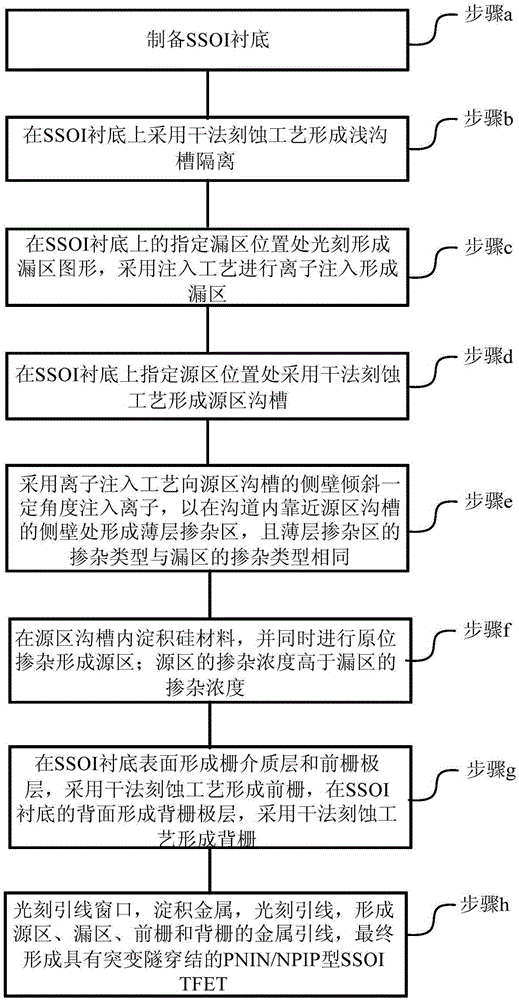

[0026] See figure 1 , figure 1 It is a flow chart of a preparation method of a PNIN / NPIP type SSOITFET with a sudden tunnel junction according to an embodiment of the present invention, and the preparation method includes the following steps:

[0027] (a) preparing an SSOI substrate;

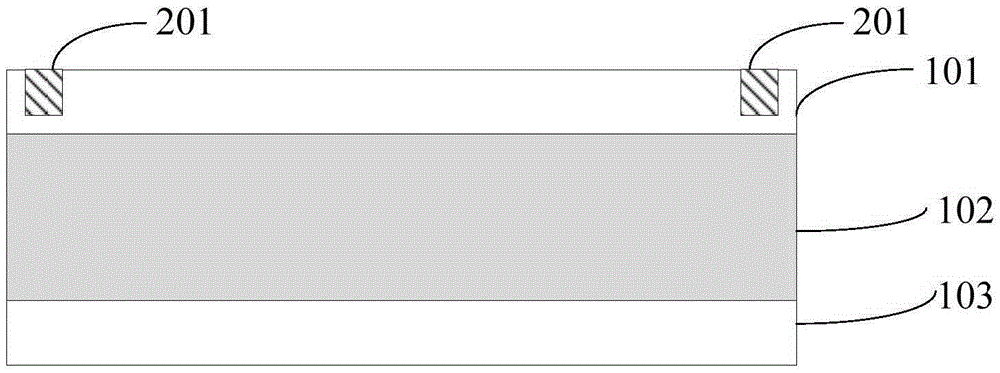

[0028] (b) forming shallow trench isolation on the SSOI substrate by using a dry etching process;

[0029] (c) Photolithographically forming a drain region pattern at a designated drain region position on the SSOI substrate, and performing ion implantation by an implantation process to form a drain region;

[0030] (d) using a dry etching process to form a source region trench at a designated source region position on the SSOI substrate;

[0031] (e) using an ion implantation process to implant ions obliquely at a certain angle to the sidewall of the trench in the source region, so as to form a thin doped region in the trench near the sidewall of the trench in the source region, and the thi...

Embodiment 2

[0076] See Figure 2a-2i , Figure 2a-Figure 2i It is a schematic diagram of a preparation method of a PNIN / NPIP type SSOITFET with an abrupt tunneling junction according to an embodiment of the present invention. Taking the preparation of a PNIN type SSOITFET with an abrupt tunneling junction with a channel length of 45 nm as an example, the specific steps are as follows:

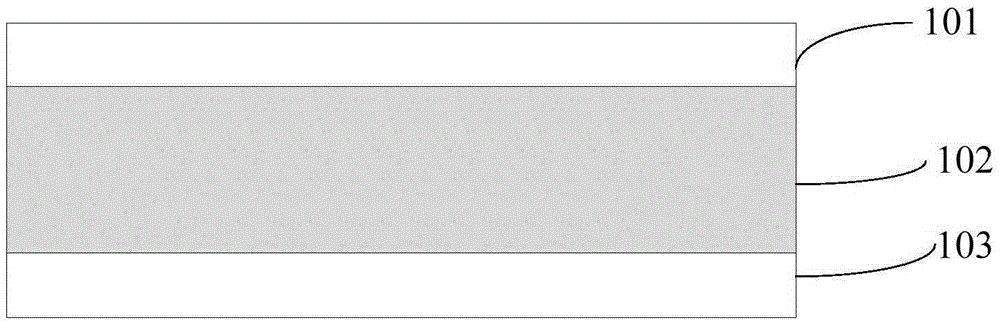

[0077] 1. Prepare SSOI substrate, such as Figure 2a Shown:

[0078] 1.1 Epitaxial growth.

[0079] Using selective epitaxy technology, a graded SiGe layer is epitaxially grown on a Si wafer at a high temperature of 800°C to 900°C, and the gas phase precursor GeH is dynamically adjusted during the epitaxial growth process 4 and SiH 2 Cl 2 The flow rate ratio of the gradient SiGe layer is controlled to increase the Ge composition of the graded SiGe layer from 0 to the Ge composition of the relaxed SiGe layer of the fixed composition, and then a layer of fixed composition is epitaxially grown at a high ...

Embodiment 3

[0140] See image 3 , image 3 It is a structural schematic diagram of a PNIN / NPIP type SSOITFET with an abrupt tunnel junction according to an embodiment of the present invention. The PNIN / NPIP SSOITFET with an abrupt tunnel junction of the present invention includes a top strained Si layer, a buried oxide layer, a bottom Si layer, a gate Dielectric layer, front gate, back gate, highly doped source region, low doped drain region and N-type / P-type thin layer.

[0141] Specifically, the SSOI substrate is prepared by intelligent stripping technology, the Ge composition of the strain-inducing layer SiGe layer is preferably 0.4, the strained Si layer is directly located on the insulating layer, and there is no strain-inducing layer SiGe layer under it, and the thickness of the strained Si layer is preferably 10-20nm, the thickness is less than the critical thickness of strained Si when the Ge composition is 0.4, and the doping concentration is less than 10 17 cm -3 .

[0142] Sp...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com