AlGaN-based tunneling junction structure based on polarization induced principle and preparation method thereof

A technology of polarization induction and tunneling junction, which is applied in semiconductor/solid-state device manufacturing, semiconductor devices, electrical components, etc., can solve the problems of poor electrical characteristics and difficult doping of AlGaN with high Al composition, and achieve good performance and improved Effect of Tunneling Chance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

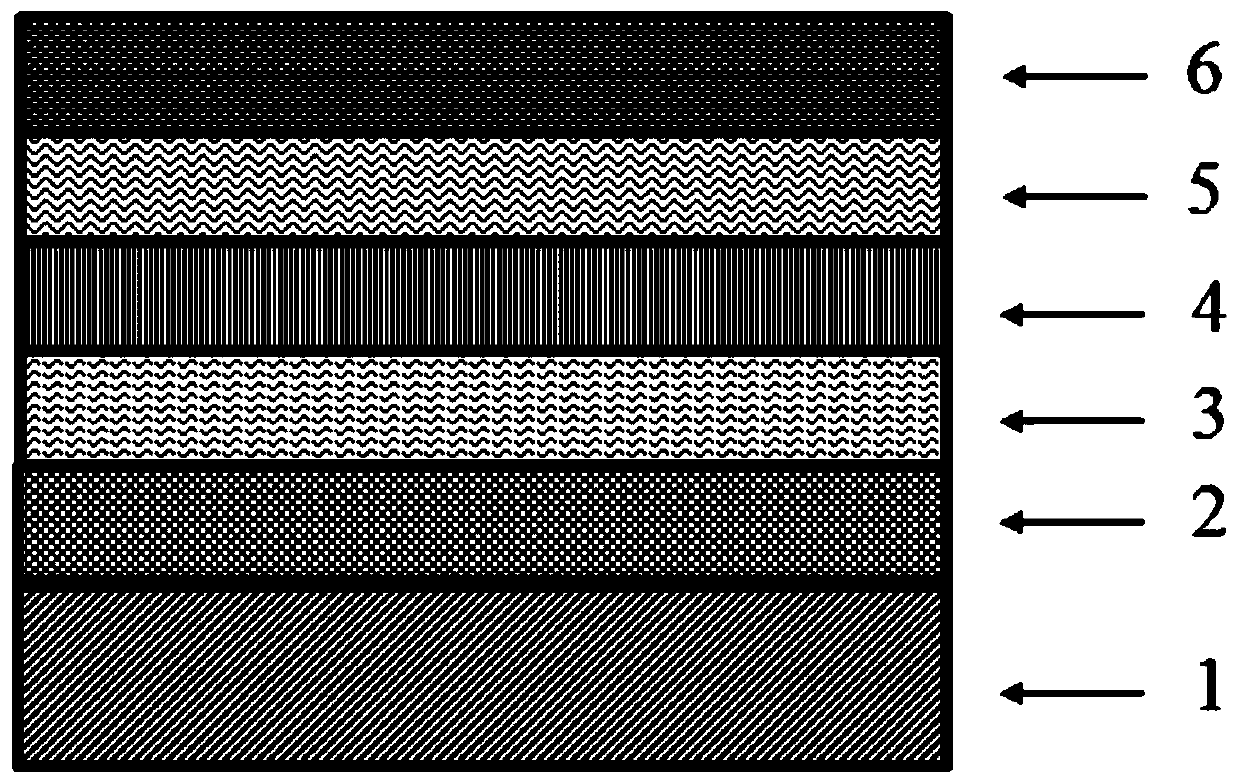

[0025] AlGaN-Based Polarization-Induced Tunneling Junctions on SiC Substrates

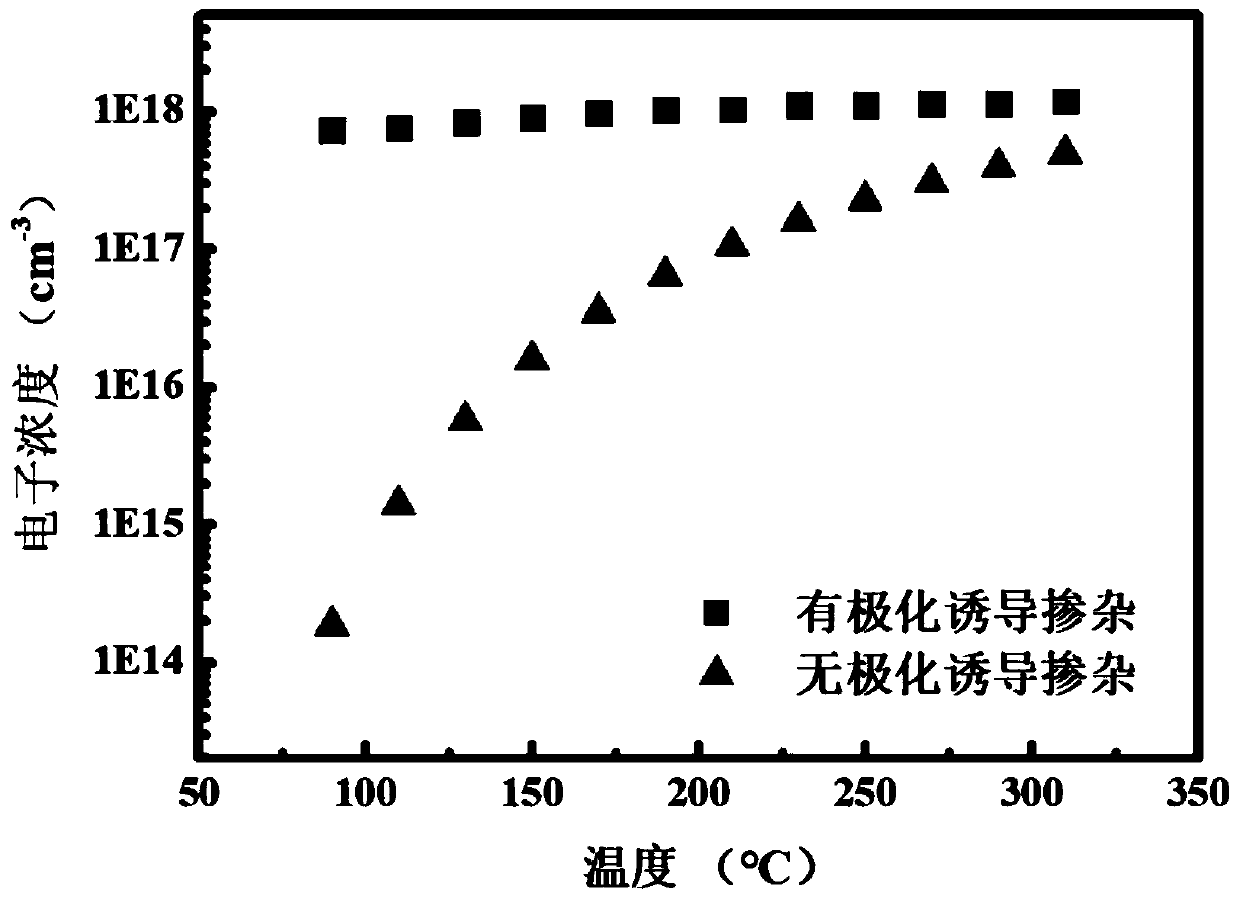

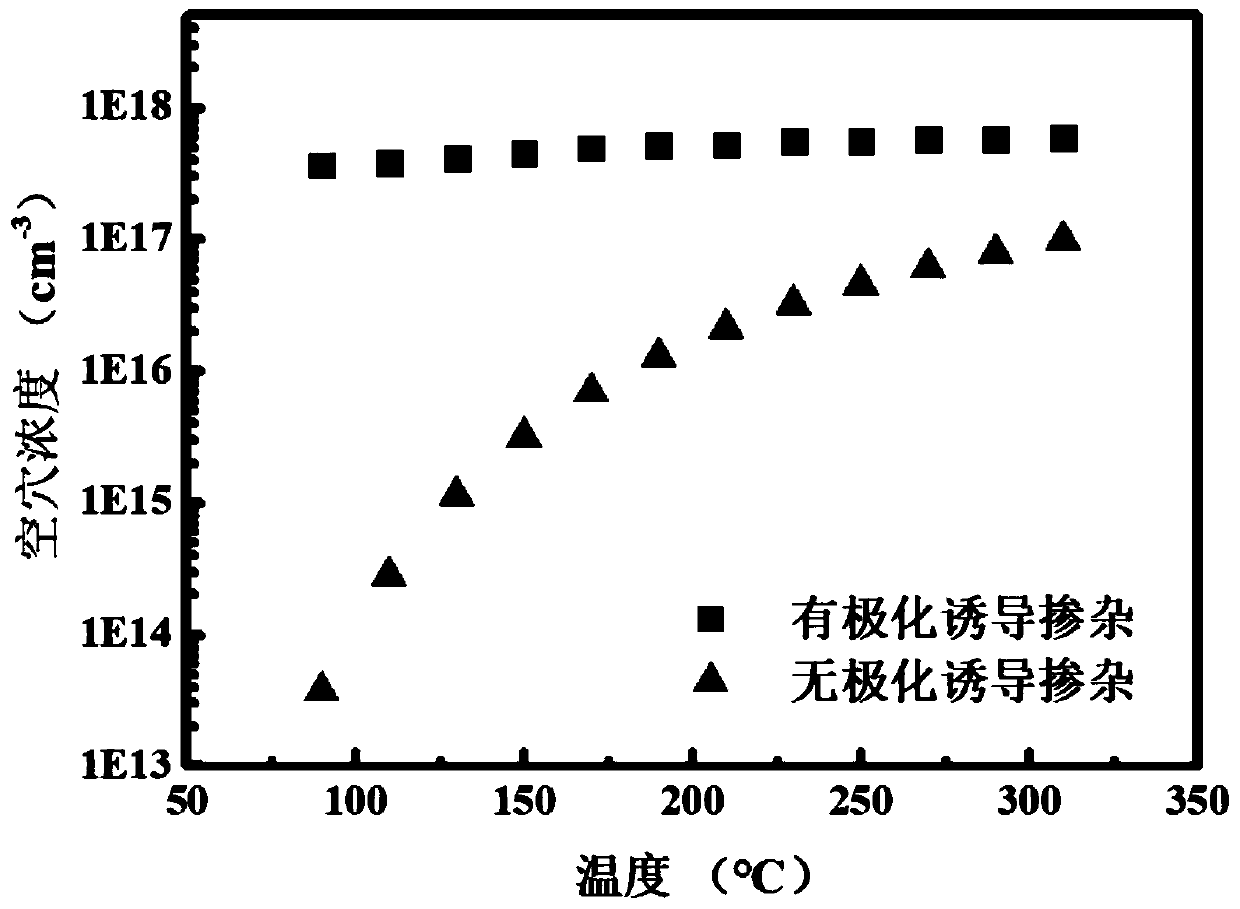

[0026] 1. Using MOCVD method, epitaxially prepare AlGaN-based polarization-induced tunneling junction structure on conductive n-type SiC substrate, such as figure 1 shown. The specific structure is as follows: in n-SiC (the doping concentration is 2×10 18 / cm 3 , the substrate can be purchased) and sequentially prepare n-Al on the substrate 1 0.3 Ga 0.7 N, template layer 2 (thickness 100nm), n-Al x1 Ga 1-x1 N polarization inducing doped layer 3 (thickness is 50nm, doping concentration is 5×10 18 / cm 3 , the TMAl source flow rate increased linearly from 7.13μmol / min to 25.67μmol / min within 300s, as shown in Table 1, the TMGa source flow rate decreased linearly from 37.78μmol / min to 18.89μmol / min, so that the x1 value linearly changed with the thickness, from 0.3 change to 0.6), Al 0.8 Ga 0.2 N insertion layer 4 (thickness 10nm, x2=0.8), p-Al x3 Ga 1-x3 N polarization inducing doped layer...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com