GaN-based LED epitaxial wafer and preparation method thereof

A technology of LED epitaxial wafers and epitaxial wafers, which is applied in the direction of electrical components, circuits, semiconductor devices, etc., can solve the problems that it is difficult to obtain a p-type layer with high hole concentration, the performance of LEDs is difficult to further improve, and the forward voltage of GaN-based LEDs is high. High-performance preparation method, low cost, and precise preparation conditions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

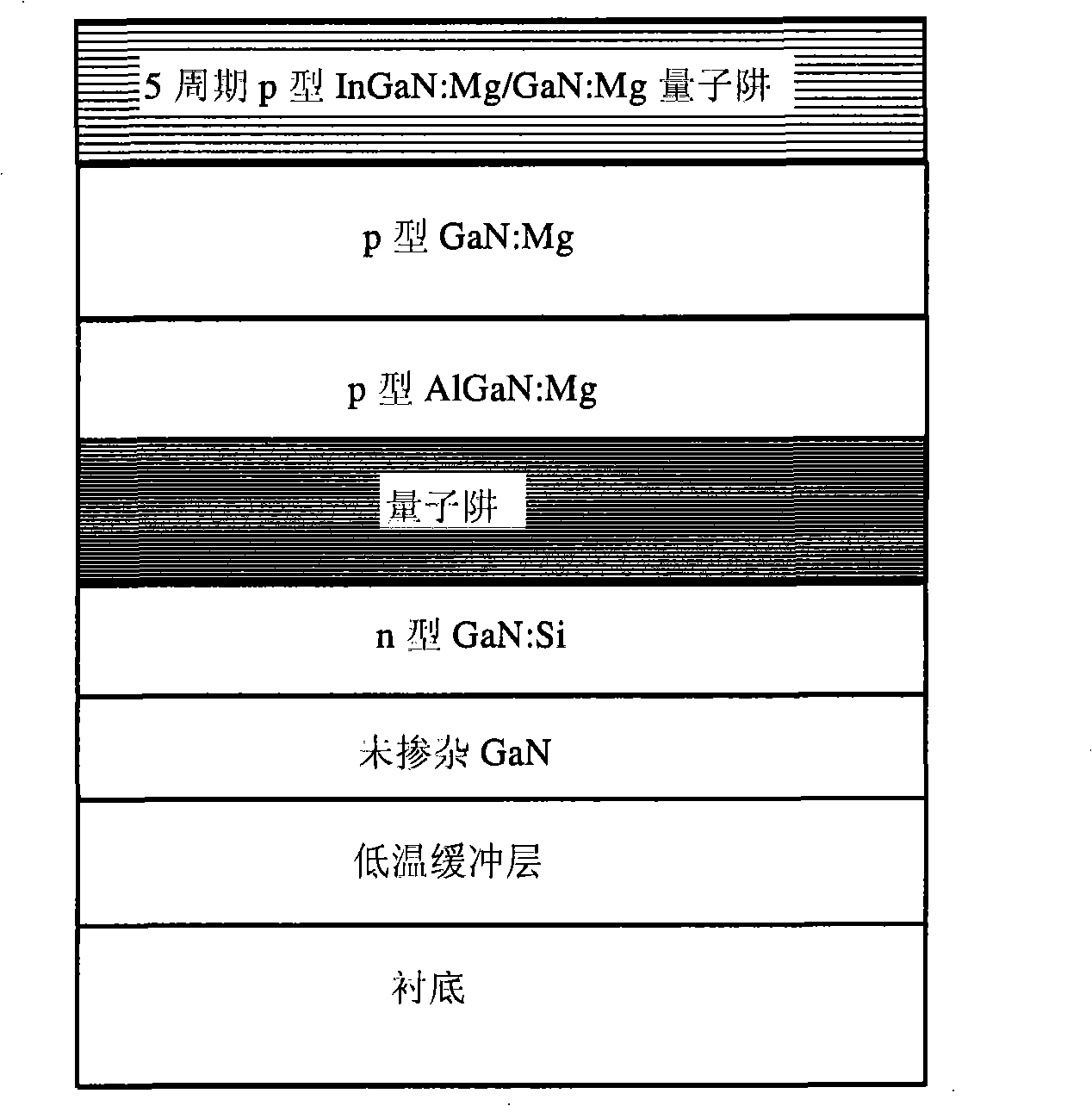

[0035] The structure of GaN-based LED epitaxial wafer with p-type contact layer is shown in the attached figure 1 As shown, from bottom to top are substrate, low temperature buffer layer, undoped GaN layer, n-type GaN layer, InGaN / GaN quantum well, p-type AlGaN and p-type GaN layer, p-type InGaN:Mg / GaN:Mg quantum well layer.

[0036] Its preparation method is:

[0037] (1) Using MOCVD equipment, heat up to 1000°C and bake the substrate for 10 minutes in a hydrogen atmosphere;

[0038] (2) Lower the temperature to 480°C, and grow a GaN low-temperature buffer layer with a thickness of 30nm on the substrate;

[0039] Raise the temperature to 1050°C to grow an undoped GaN layer with a thickness of 1.0μm;

[0040] (3) growing an n-type GaN:Si layer with a thickness of 2.0 μm at a temperature of 1000° C.;

[0041] (4) InGaN / GaN quantum wells were grown at 720°C, and the number of quantum well periods was 5;

[0042] (5) Raise the temperature to 1000°C to grow a p-type AlGaN:Mg...

Embodiment 2

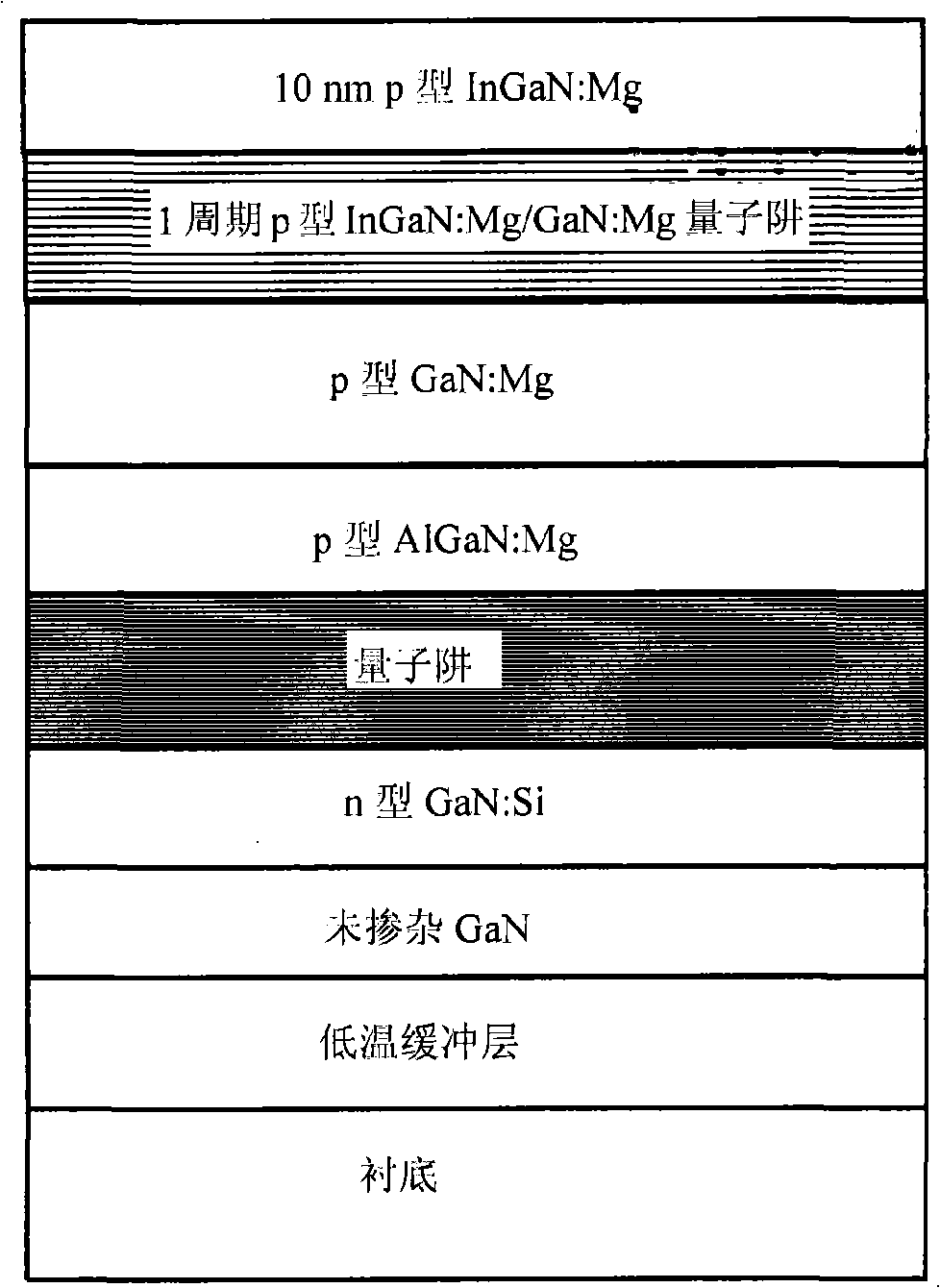

[0047] The structure of GaN-based LED epitaxial wafer with p-type contact layer is shown in the attached figure 2As shown, from bottom to top are substrate, low temperature buffer layer, undoped GaN layer, n-type GaN layer, InGaN / GaN quantum well, p-type AlGaN layer, p-type GaN, p-type InGaN:Mg / GaN:Mg Quantum well layer, p-type InGaN:Mg.

[0048] Its preparation method is:

[0049] (1) Using MOCVD equipment, heat up to 1000°C and bake the substrate for 10 minutes in a hydrogen atmosphere;

[0050] (2) Lower the temperature to 480°C, and grow a GaN low-temperature buffer layer with a thickness of 30nm on the substrate;

[0051] Raise the temperature to 1050°C to grow an undoped GaN layer with a thickness of 1.0μm;

[0052] (3) growing an n-type GaN:Si layer with a thickness of 2.0 μm at a temperature of 1000° C.;

[0053] (4) InGaN / GaN quantum wells were grown at 750°C, and the number of quantum well periods was 8;

[0054] (5) Raise the temperature to 1000°C to grow a p-...

Embodiment 3

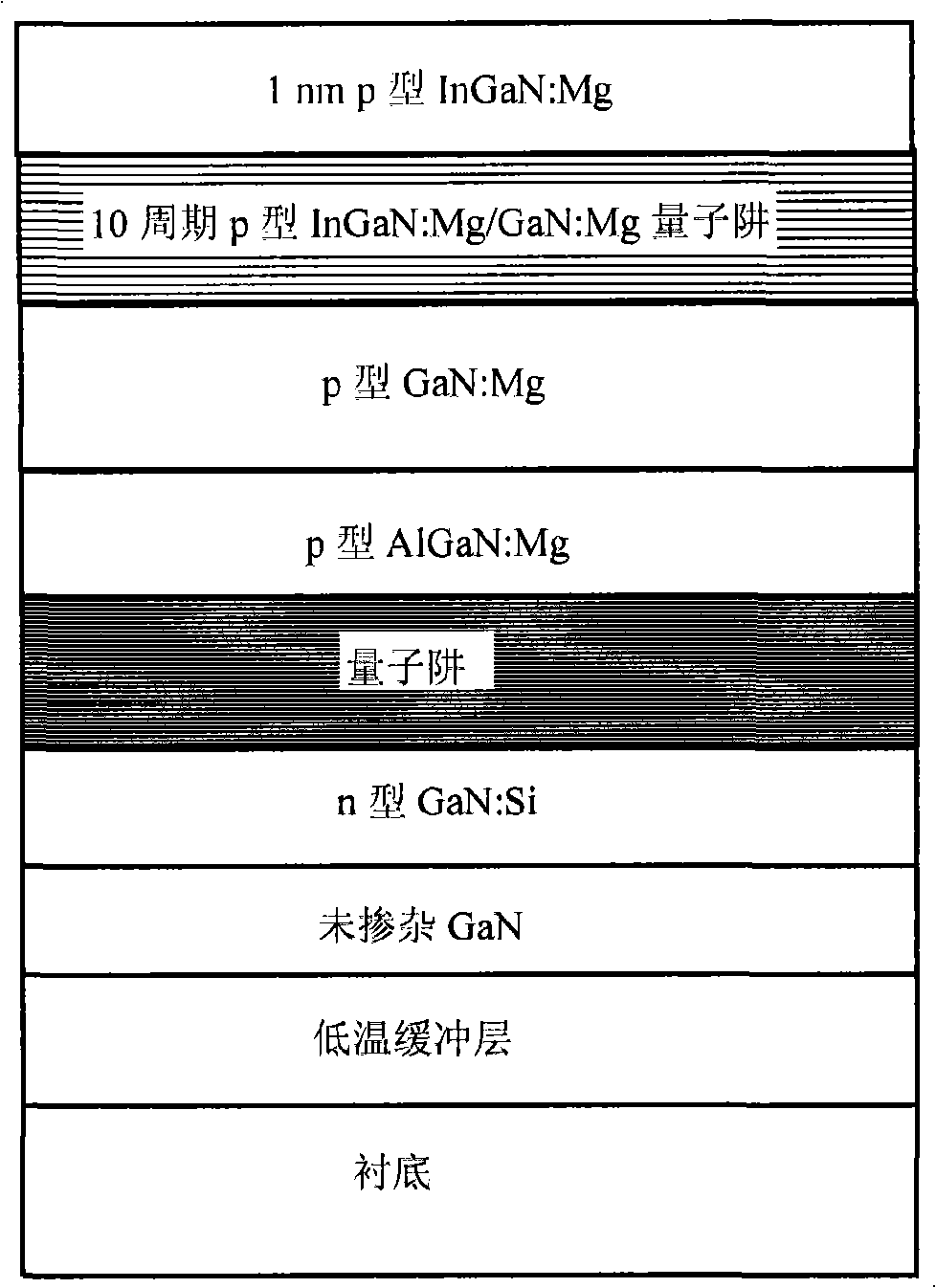

[0060] The structure of GaN-based LED epitaxial wafer with p-type contact layer is shown in the attached image 3 As shown, from bottom to top are substrate, low temperature buffer layer, undoped GaN layer, n-type GaN layer, InGaN / GaN quantum well, p-type AlGaN layer, p-type GaN, p-type InGaN:Mg / GaN:Mg Quantum well layer, p-type InGaN:Mg.

[0061] Its preparation method is:

[0062] (1) Using MOCVD equipment, heat up to 1000°C and bake the substrate for 10 minutes in a hydrogen atmosphere;

[0063] (2) Lower the temperature to 480°C, and grow a GaN low-temperature buffer layer with a thickness of 30nm on the substrate;

[0064] Raise the temperature to 1050°C to grow an undoped GaN layer with a thickness of 1.0μm;

[0065] (3) growing an n-type GaN:Si layer with a thickness of 2.0 μm at a temperature of 1000° C.;

[0066] (4) InGaN / GaN quantum wells were grown at 680°C, and the number of quantum well periods was 5;

[0067] (5) Raise the temperature to 1000°C to grow a p-...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com