Niobium and tungsten alloy and preparation method thereof

An alloy, niobium-tungsten technology, applied in the field of niobium-tungsten alloy and its preparation, can solve the problem of insufficient strength of niobium-tungsten alloy, and achieve the effect of excellent strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

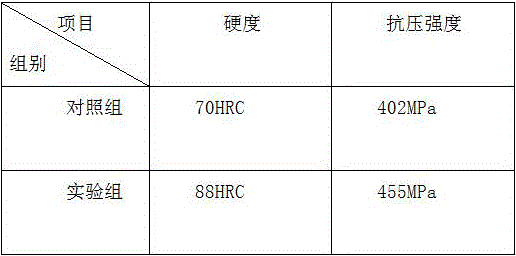

Examples

Embodiment 1

[0018] A niobium-tungsten alloy, comprising the following raw materials in parts by weight: 102 parts of niobium, 14 parts of tungsten carbide powder, 5 parts of zirconium, 1 part of tin, 1 part of iridium, 5 parts of hafnium carbide, 1 part of titanium carbide, and tantalum carbide 2 parts ytterbium oxide, 1 part sintered aluminum, 1 part aluminum nitride, 1 part magnesium nitride, 1 part silicon dioxide, 1 part yttrium oxide, and 2 parts boron carbide.

[0019] A kind of preparation method of niobium tungsten alloy comprises the following steps:

[0020] 1) Pour 102 parts of niobium, 14 parts of tungsten carbide powder, 5 parts of zirconium, 1 part of tin, 1 part of iridium, 5 parts of hafnium carbide, 1 part of titanium carbide, 2 parts of tantalum carbide and 2 parts of ytterbium oxide into the metal smelting furnace, then heated to 900°C, and stirred after all the raw materials were completely melted to obtain liquid metal for later use;

[0021] 2) Pour 1 part of sinter...

Embodiment 2

[0025] A niobium-tungsten alloy, comprising the following raw materials in parts by weight: 100 parts of niobium, 16 parts of tungsten carbide powder, 7 parts of zirconium, 3 parts of tin, 3 parts of iridium, 7 parts of hafnium carbide, 3 parts of titanium carbide, and tantalum carbide 4 parts of ytterbium oxide, 4 parts of sintered aluminum, 3 parts of aluminum nitride, 3 parts of magnesium nitride, 3 parts of silicon dioxide, 3 parts of yttrium oxide, and 4 parts of boron carbide.

[0026] A preparation method of niobium-tungsten alloy, comprising the following steps:

[0027] 1) Pour 100 parts of niobium, 16 parts of tungsten carbide powder, 7 parts of zirconium, 3 parts of tin, 3 parts of iridium, 7 parts of hafnium carbide, 3 parts of titanium carbide, 4 parts of tantalum carbide and 4 parts of ytterbium oxide into the metal smelting furnace, then heated to 900°C, and stirred after all the raw materials were completely melted to obtain liquid metal for later use;

[0028...

Embodiment 3

[0032] A niobium-tungsten alloy, comprising the following raw materials in parts by weight: 101 parts of niobium, 15 parts of tungsten carbide powder, 6 parts of zirconium, 2 parts of tin, 2 parts of iridium, 6 parts of hafnium carbide, 2 parts of titanium carbide, and tantalum carbide 3 parts ytterbium oxide, 2 parts sintered aluminum, 2 parts aluminum nitride, 2 parts magnesium nitride, 2 parts silicon dioxide, 2 parts yttrium oxide, and 3 parts boron carbide.

[0033] A preparation method of niobium-tungsten alloy, comprising the following steps:

[0034] 1) Pour 101 parts of niobium, 15 parts of tungsten carbide powder, 6 parts of zirconium, 2 parts of tin, 2 parts of iridium, 6 parts of hafnium carbide, 2 parts of titanium carbide, 3 parts of tantalum carbide and 3 parts of ytterbium oxide into the metal smelting furnace, then heated to 900°C, and stirred after all the raw materials were completely melted to obtain liquid metal for later use;

[0035] 2) Pour 2 parts of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com