Method for realizing gallium nitride p-type doping based on Mg ion implantation and high-temperature annealing process

A technology of high-temperature annealing and ion implantation, which is applied in the manufacture of electrical components, semiconductor/solid-state devices, circuits, etc., can solve problems such as immaturity, low activation rate, and material surface decomposition, and achieves inhibition of decomposition, low cost, and reduced material damage Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

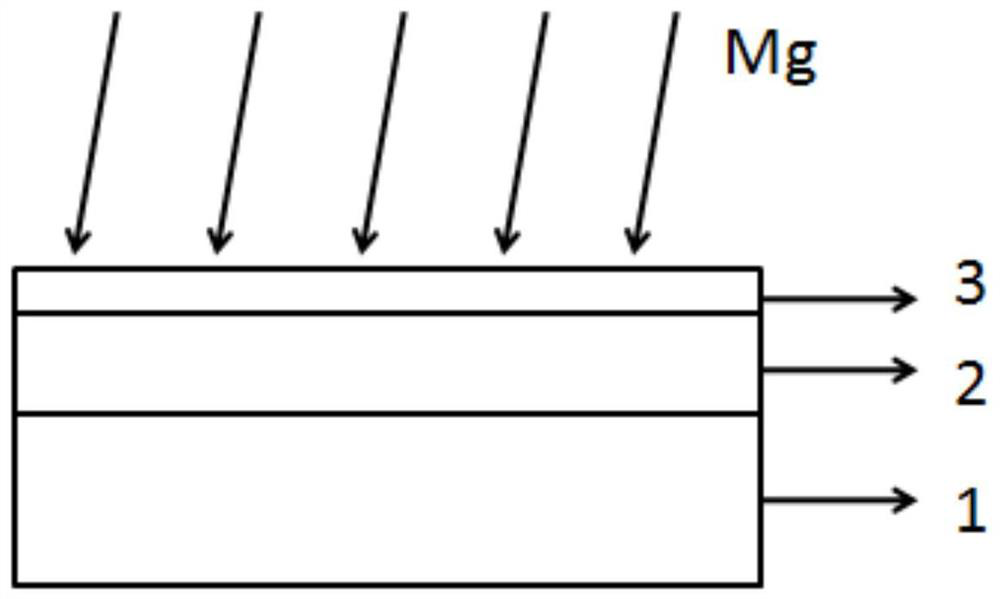

[0035] A method for realizing p-type doping of gallium nitride based on Mg ion implantation and high temperature annealing process, comprising the following steps:

[0036] S1: Deposit 20nm AlN material on the surface of GaN sample,

[0037] S2: Select the appropriate energy and dose of Mg ion implantation for ion implantation. In this embodiment, two-step implantation is selected. The first implantation energy is 30keV, and the dose is 1.5×10 14 cm -2 , the second implantation energy is 60keV, and the dose is 2×10 14 cm -2 ,

[0038] S3: remove AlN material,

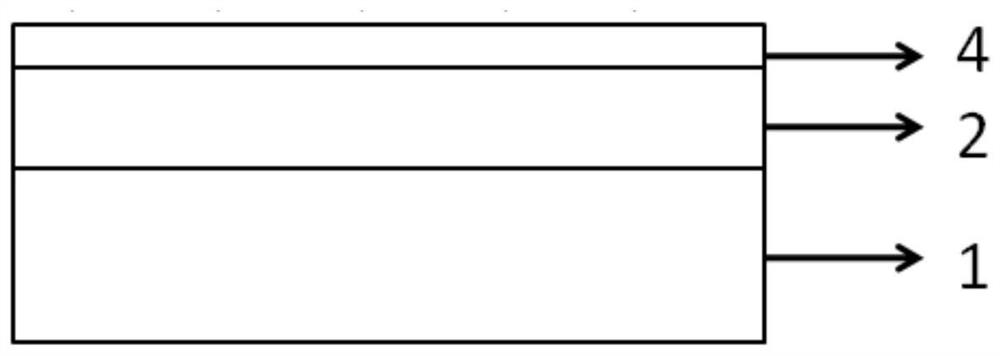

[0039] S4: Deposit 200nm silicon dioxide on the surface of the GaN sample as a protective layer during high temperature annealing,

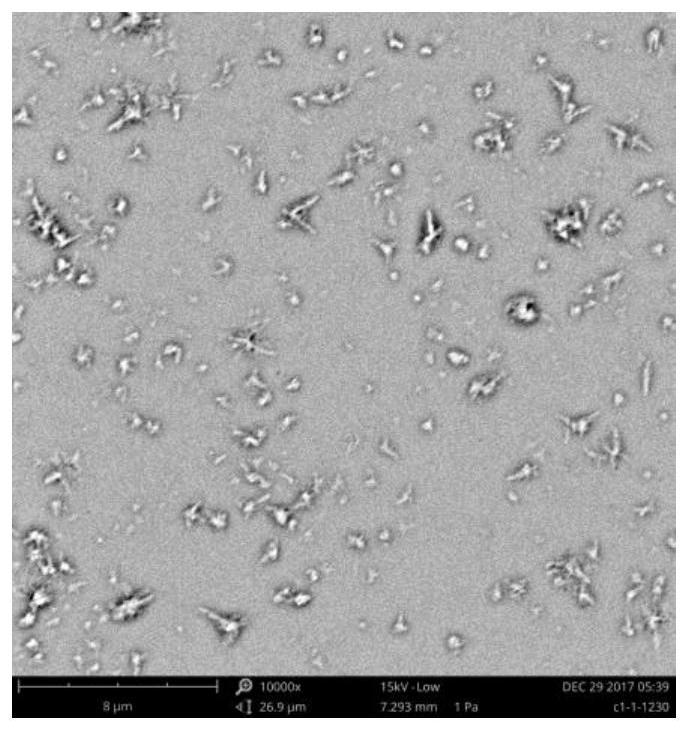

[0040]S5: Perform high-temperature annealing on the GaN sample, the gas atmosphere is a nitrogen atmosphere, the temperature is 1230°C, and the annealing time is 30 minutes.

[0041] S6: Remove the silicon dioxide high-temperature annealing protective layer on the GaN surface to obta...

Embodiment 2

[0046] A method for realizing p-type doping of gallium nitride based on Mg ion implantation and high temperature annealing process, comprising the following steps:

[0047] S1: Deposit 20nm AlN material on the surface of GaN sample,

[0048] S2: Select the appropriate energy and dose of Mg ion implantation for ion implantation. In this embodiment, two-step implantation is selected. The first implantation energy is 250keV, and the dose is 4×10 14 cm -2 , the second implantation energy is 500keV, and the dose is 6×10 14 cm -2 ,

[0049] S3: remove AlN material,

[0050] S4: Deposit 200nm silicon dioxide on the surface of the GaN sample as a protective layer during high temperature annealing,

[0051] S5: Perform high-temperature annealing on the GaN sample, the gas atmosphere is a nitrogen atmosphere, the temperature is 1230°C, and the annealing time is 30 minutes.

[0052] S6: Remove the silicon dioxide high-temperature annealing protective layer on the GaN surface to obt...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com