Cementitious capillary crystalline waterproofing coating, preparation method and using method thereof

A technology for penetrating crystalline masterbatches and waterproof coatings. It is applied in the field of waterproof coatings. It can solve the problems of single type of active masterbatches, permeability performance, crystallization performance and waterproof performance that need to be further improved, so as to achieve strong coating, improve impermeability, Enhanced compactness effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

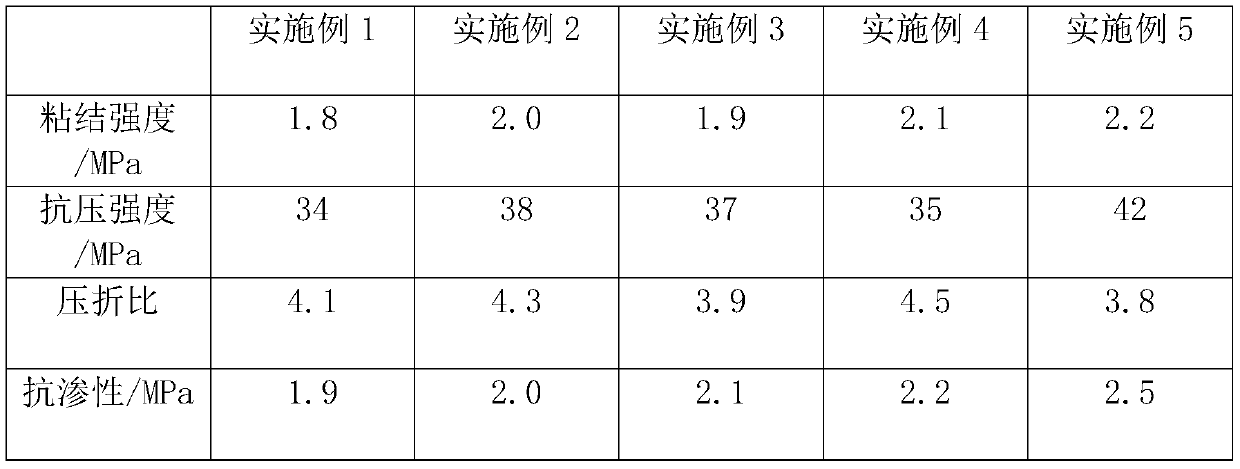

Examples

Embodiment 1

[0015] A cement-based osmotic crystalline waterproof coating, comprising the following components in parts by weight: 45 parts of 42.5 ordinary Portland cement, 45 parts of 70-120 mesh quartz sand, 1.5 parts of dispersible latex powder, 2 parts of osmotic crystalline masterbatch, hydroxyl 0.1 part of propyl methylcellulose, 0.2 part of silicone defoamer; the infiltration crystallization masterbatch includes the following raw materials in percentage by weight: barium oxide 55%, magnesium nitride 10%, chromium sulfate dodecahydrate 5%, copper sulfate 5%, magnesium sulfate 15%, maleic acid-acrylic acid copolymer sodium salt 10%.

Embodiment 2

[0017] A cement-based osmotic crystalline waterproof coating, comprising the following components in parts by weight: 46 parts of 42.5 ordinary Portland cement, 46 parts of 70-120 mesh quartz sand, 1.6 parts of dispersible latex powder, 2.2 parts of osmotic crystalline masterbatch, hydroxyl 0.13 part of propyl methylcellulose, 0.23 part of organosilicon defoamer; The infiltration crystallization masterbatch comprises following raw materials in percentage by weight: 46% of barium oxide, 12% of magnesium nitride, 6% of chromium sulfate dodecahydrate, copper sulfate 6%, magnesium sulfate 18%, maleic acid-acrylic acid copolymer sodium salt 12%.

Embodiment 3

[0019] A cement-based osmotic crystalline waterproof coating, comprising the following components in parts by weight: 48 parts of 42.5 ordinary Portland cement, 48 parts of 70-120 mesh quartz sand, 1.8 parts of dispersible latex powder, 2.3 parts of osmotic crystalline masterbatch, hydroxyl 0.16 part of propyl methylcellulose, 0.26 part of organosilicon defoamer; The infiltration crystallization masterbatch comprises following raw materials in weight percent: 40% of barium oxide, 13% of magnesium nitride, 7% of chromium sulfate dodecahydrate, copper sulfate 8%, magnesium sulfate 18%, maleic acid-acrylic acid copolymer sodium salt 14%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com