Shell and manufacturing method thereof

A manufacturing method and shell technology, which are applied in the directions of metal shells, cabinets/cabinets/drawer parts, ion implantation plating, etc., can solve the problem of difficulty in maintaining decorative appearance, and inability to effectively improve the corrosion resistance of magnesium or magnesium alloy substrates. performance, low electrode potential, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

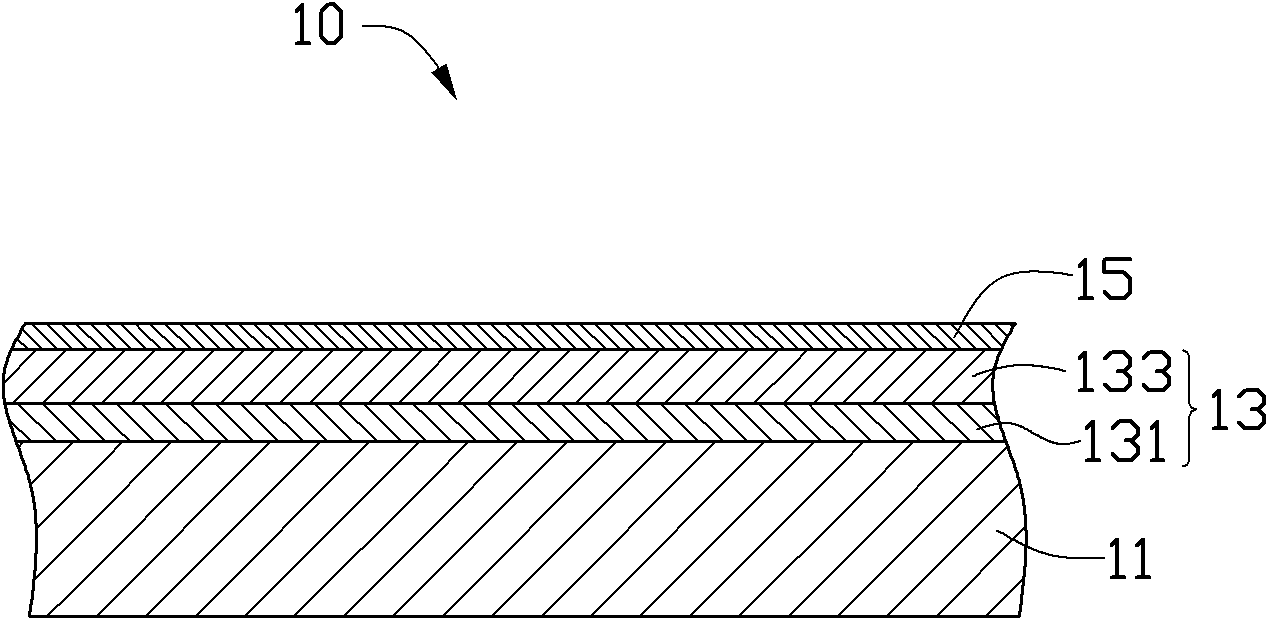

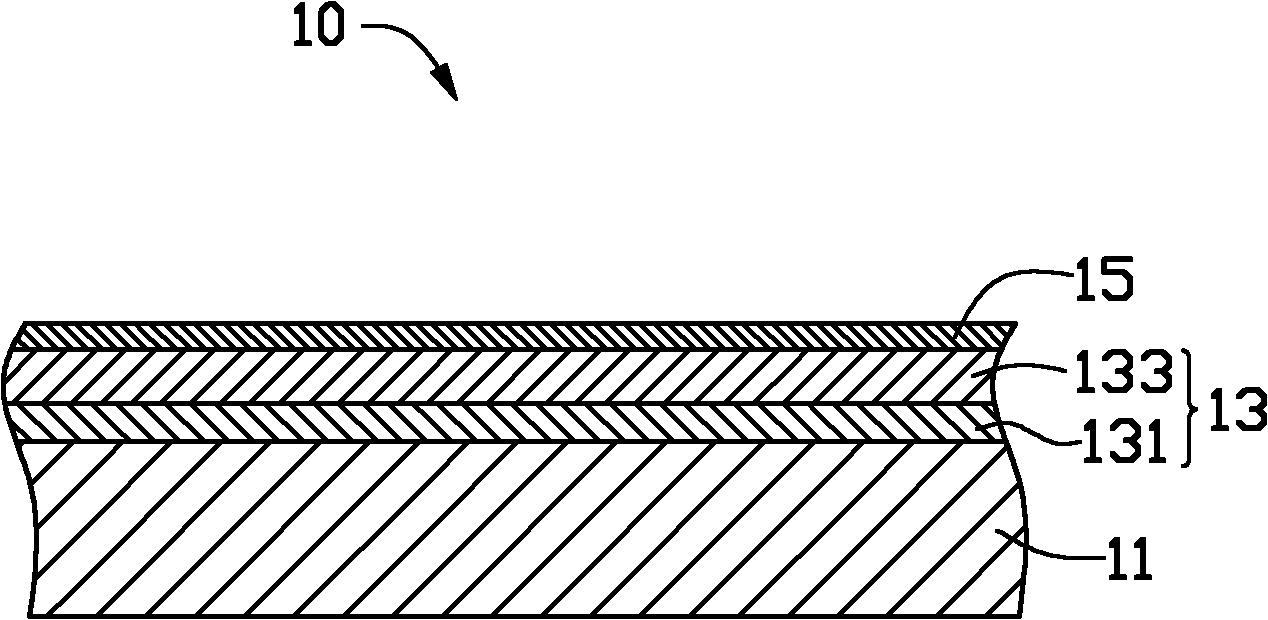

[0020] see figure 1 , The casing 10 of a preferred embodiment of the present invention includes a magnesium or magnesium alloy substrate 11 , an anti-corrosion layer 13 and a color layer 15 sequentially formed on the magnesium or magnesium alloy substrate 11 . The casing 10 can be a casing of a 3C electronic product, and can also be an industrial, building component, and a vehicle component such as an automobile.

[0021] The anti-corrosion layer 13 includes a magnesium layer 131 and a magnesium oxide layer 133 , the magnesium layer 131 is formed on the surface of the substrate 11 , and the magnesium oxide layer 133 is formed on the surface of the magnesium layer 131 . The thickness of the magnesium layer 131 is 1.0-3.0 μm; the thickness of the magnesium oxide layer 133 is 0.5-1.0 μm.

[0022] The color layer 15 is a Ti-N layer with a thickness of 1.0-3.0 μm. It can be understood that the color layer 15 can also be a Cr-N layer or other decorative film layers.

[0023] Both...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com