Casing and manufacturing method thereof

一种制造方法、壳体的技术,应用在金属外壳、离子注入镀覆、涂层等方向,能够解决脱落、不能有效提高铝、铝合金、镁或镁合金基体耐腐蚀性能、微电池腐蚀等问题

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

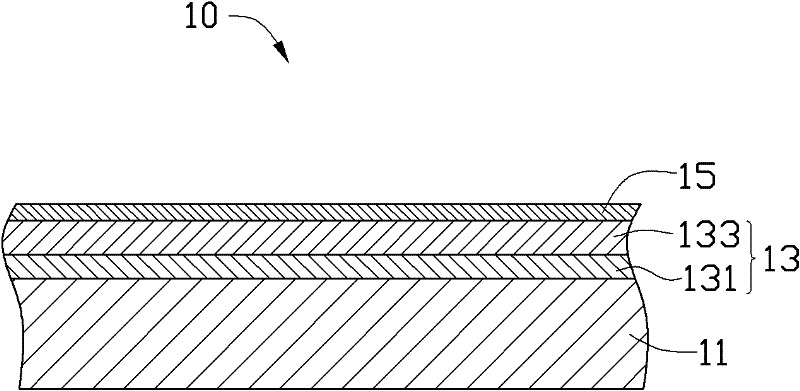

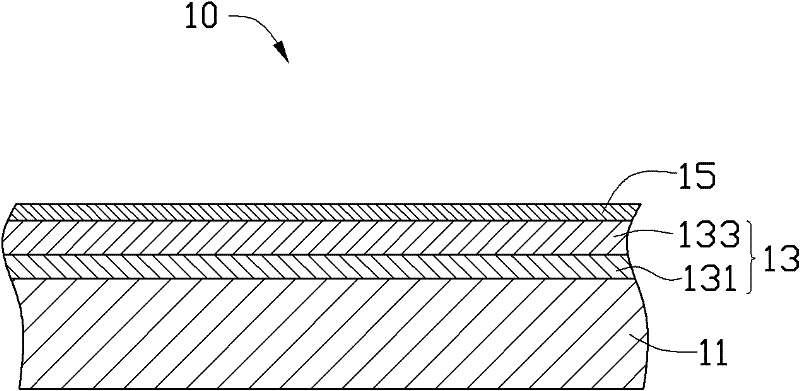

[0025] see figure 1 , The casing 10 of a preferred embodiment of the present invention includes an aluminum / magnesium metal base 11 , an anti-corrosion layer 13 and a color layer 15 sequentially formed on the aluminum / magnesium metal base 11 . The casing 10 can be a casing of a 3C electronic product, and can also be an industrial, building component, and a vehicle component such as an automobile.

[0026] The aluminum / magnesium metal base 11 is made of aluminum, aluminum alloy, magnesium or magnesium alloy.

[0027] The anti-corrosion layer 13 includes an aluminum-copper film 131 and an aluminum nitride gradient film 133, the aluminum-copper film 131 is formed on the surface of the aluminum / magnesium metal substrate 11, and the aluminum nitride gradient film 133 is formed on the aluminum-copper film 131 s surface. The thickness of the Al-Cu film 131 is 1.0-3.0 μm; the thickness of the aluminum nitride gradient film 133 is 0.5-1.0 μm. The number and percentage of N atoms in ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com